What Does The Drive Belt Do

So, you're diving into the world of automotive systems and have your sights set on understanding the drive belt, sometimes called the serpentine belt. Excellent choice! It's a critical component, and mastering its function and maintenance can save you time, money, and headaches. This deep dive will give you the knowledge needed to confidently diagnose issues, perform replacements, and understand how this seemingly simple belt plays a vital role in your vehicle’s operation.

Purpose

Why bother learning about the drive belt? Several reasons. Firstly, if it fails, essential vehicle systems like the power steering, alternator, and air conditioning can grind to a halt. Recognizing the symptoms of a failing belt early on can prevent a roadside breakdown. Secondly, understanding the belt’s routing and tensioning is crucial for performing replacements correctly. Over-tensioning or improper routing can damage components. Finally, if you're planning modifications or upgrades to accessories that are driven by the belt, knowing the system inside and out will allow you to choose the right belt length and ensure compatibility. We have a detailed diagram illustrating typical drive belt routing available for download at the end of this article.

Key Specs and Main Parts

Let's break down the key aspects of the drive belt and its supporting components:

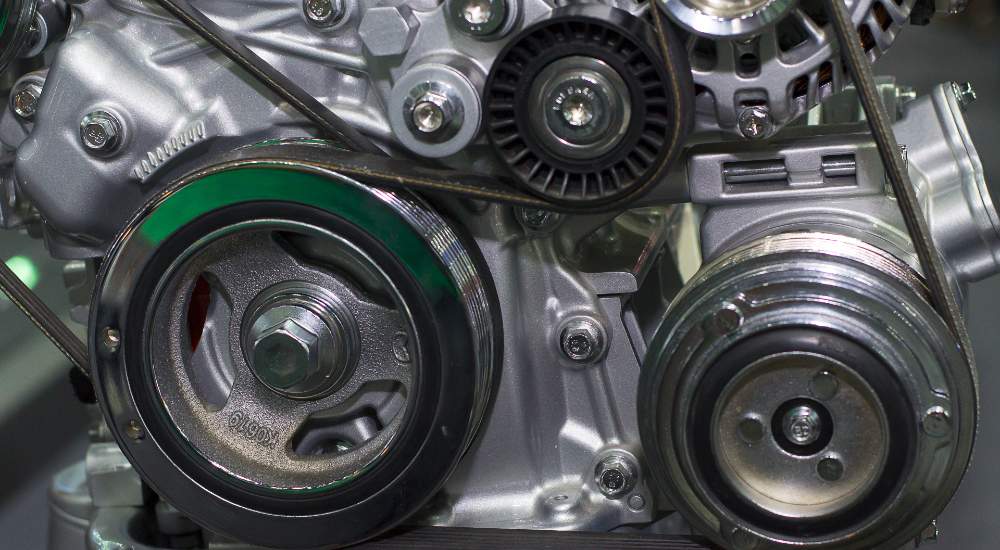

- The Drive Belt (Serpentine Belt): Usually made of reinforced rubber, the drive belt transfers rotational power from the engine's crankshaft to various accessories. Modern vehicles typically use a single, long "serpentine" belt to drive multiple components.

- Crankshaft Pulley (Crank Pulley): This pulley, attached to the crankshaft, is the source of rotational power for the entire drive belt system. It is the primary driver.

- Alternator Pulley: The alternator generates electricity to charge the battery and power electrical components. The drive belt spins the alternator pulley, causing the alternator to produce power.

- Power Steering Pump Pulley: In vehicles with hydraulic power steering, the drive belt spins the power steering pump. This pump provides hydraulic pressure to assist steering.

- Air Conditioning Compressor Pulley: The A/C compressor compresses refrigerant, a process essential for cooling the vehicle's cabin. The drive belt spins the compressor pulley, driving the compressor.

- Idler Pulley: An idler pulley is a smooth pulley used to guide the belt and maintain proper routing, preventing it from contacting other components or itself. It doesn't drive any accessory.

- Tensioner Pulley (Belt Tensioner): The tensioner maintains the correct amount of tension on the drive belt. This is crucial for proper operation and preventing belt slippage or premature wear. Tensioners can be spring-loaded or hydraulic. They apply constant pressure to the belt, compensating for stretching and wear.

Key Specifications: The most important specification is the belt length, usually measured in millimeters or inches. The correct length is critical for proper tensioning and operation. Belt width and rib profile (the shape and number of the "grooves" on the belt) are also important for compatibility with the pulleys. These specifications are usually printed on the belt itself.

How It Works

The operating principle is fairly straightforward. The crankshaft, powered by the engine, spins the crankshaft pulley. This rotational energy is then transferred to the drive belt, which wraps around all the other pulleys in the system. As the crankshaft pulley spins, it forces the drive belt to rotate, causing all the accessory pulleys connected to the belt to spin as well. Each accessory, in turn, performs its specific function.

The tensioner plays a vital role in this process. Without proper tension, the belt would slip on the pulleys, reducing the efficiency of the accessories and potentially damaging the belt. The tensioner applies constant pressure to the belt, ensuring that it maintains adequate grip on the pulleys, even as the belt stretches over time.

Real-World Use – Basic Troubleshooting Tips

Here are some common symptoms of a failing drive belt and basic troubleshooting steps:

- Squealing or Chirping Noise: This is often the first sign of a problem. It can be caused by a loose belt, a worn belt, or a glazed (shiny) belt surface. Try tightening the belt tensioner (if adjustable) or replacing the belt. A belt dressing product can provide temporary relief, but it's often a band-aid fix. Also, check the pulleys for damage or misalignment.

- Cracked or Frayed Belt: Visual inspection is crucial. Cracks, fraying, or missing ribs indicate a worn belt that needs replacement. Don’t wait until it breaks completely.

- Accessory Malfunctions: If your power steering suddenly becomes difficult, your alternator stops charging the battery, or your A/C blows warm air, a slipping or broken drive belt could be the culprit.

- Visible Belt Dust: Excessive black dust around the belt or pulleys indicates wear and tear and suggests the belt needs replacement.

- Belt Slippage in Wet Conditions: A worn or glazed belt is more likely to slip when wet. Replacement is usually the best solution.

When troubleshooting, remember to always disconnect the negative battery cable to prevent electrical shocks. Rotate the belt by hand to inspect its entire surface. Pay close attention to the ribs and the back of the belt.

Safety

Working around the drive belt system can be hazardous if you're not careful. Here are some safety precautions to keep in mind:

- Never work on the drive belt system with the engine running. This is extremely dangerous and can result in serious injury.

- Disconnect the negative battery cable before starting any work to prevent accidental starting.

- Wear safety glasses to protect your eyes from flying debris.

- Be careful of hot engine components. Allow the engine to cool down completely before working on the drive belt system.

- Keep your hands, hair, and clothing away from moving parts. The rotating belt and pulleys can quickly pull you in, causing serious injury.

- Use the correct tools for the job. Trying to force things can damage components or lead to injury.

- The tensioner spring is under considerable force. When removing the belt, use the correct tool to relieve the tension and avoid injury. The spring can snap back forcefully if not handled properly.

Important Note: The crankshaft pulley is directly connected to the engine's rotating assembly. Any tools or objects left in the path of the belt can be forcefully thrown out, causing severe damage and potential injury.

Drive Belt Diagram Download

To help you further understand the drive belt system, we have created a detailed diagram illustrating typical drive belt routing. The diagram includes labels for all the major components and provides a visual reference for belt installation and troubleshooting. Click here to download the diagram. It is provided as a PDF file.