What Does The V Stand For In V8

Alright, let's dive into the heart of that V8 roar. We’re going to break down what that "V" actually signifies and how it all comes together. Understanding the V8 engine, especially its configuration, is fundamental whether you're tackling a repair, considering performance modifications, or just expanding your automotive knowledge. It’s not just about brute power; it’s about engineering ingenuity. This explanation is geared toward the DIY enthusiast who isn't afraid to get their hands dirty and wants to understand the "why" behind the "how." Plus, we have a detailed diagram of a typical V8 available for download, which you can use as a reference as we go through this.

Key Specs and Main Parts of a V8 Engine

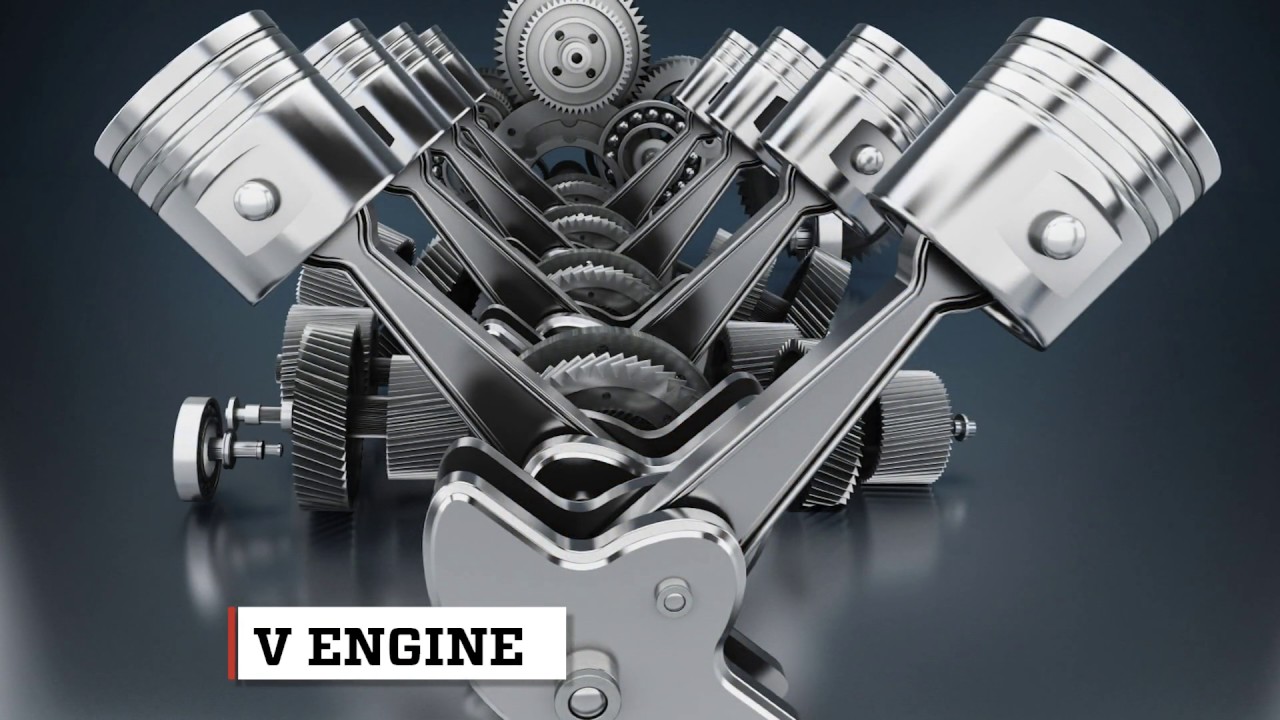

Before we get into the "V," let's briefly review the core components that make a V8 a V8. The "8" tells you there are eight cylinders. These are arranged in two banks of four cylinders each, set at an angle to each other, forming the "V" shape. Here are some key specs and main parts:

- Engine Block: The foundation of the engine, housing the cylinders, coolant passages, and oil galleries. Think of it as the skeleton of the engine.

- Cylinders: Where the combustion of fuel and air happens. They are precisely machined bores where the pistons travel.

- Pistons: Move up and down inside the cylinders, driven by the expanding gases from combustion. They are connected to the connecting rods.

- Connecting Rods: Link the pistons to the crankshaft, converting linear motion into rotational motion.

- Crankshaft: The rotating shaft that converts the reciprocating motion of the pistons into rotational motion, ultimately powering the wheels. It's the heart of the engine's power output.

- Cylinder Heads: Located atop the engine block, they contain the intake and exhaust valves, spark plugs, and combustion chambers. They control the flow of air and fuel in and out of the cylinders.

- Valves (Intake & Exhaust): Control the flow of air and fuel into the cylinders (intake) and the exhaust gases out (exhaust).

- Camshaft: Controls the opening and closing of the valves, synchronized with the crankshaft's rotation. It's like the conductor of the engine's airflow orchestra.

- Spark Plugs: Ignite the air-fuel mixture in the cylinders, initiating combustion.

- Intake Manifold: Distributes the air-fuel mixture to the cylinders.

- Exhaust Manifold: Collects the exhaust gases from the cylinders.

Typical specs often include:

- Displacement: The total volume displaced by all the pistons during one stroke, usually measured in cubic inches (cu in) or liters (L). For example, a 5.7L V8.

- Compression Ratio: The ratio of the volume of the cylinder when the piston is at the bottom of its stroke (bottom dead center) to the volume when the piston is at the top of its stroke (top dead center). It impacts engine efficiency and power.

- Firing Order: The sequence in which the cylinders fire. This is crucial for engine balance and smooth operation. A common firing order might be 1-8-4-3-6-5-7-2.

Deciphering the "V": Why the Angle Matters

The "V" in V8 refers to the arrangement of the cylinders. Instead of all eight cylinders being in a straight line (an inline engine), they are split into two banks of four, forming a "V" shape when viewed from the front or rear of the engine. This configuration offers several advantages:

- Shorter Engine Length: V8 engines are significantly shorter than inline-8 engines. This is critical for fitting the engine within the engine bay of a vehicle.

- Improved Balance: The V configuration, especially with a properly designed crankshaft and firing order, can improve engine balance, reducing vibrations and contributing to smoother operation. Think of it like two smaller, balanced engines working in tandem.

- Increased Power Potential: The V8 configuration provides a good balance of displacement, cylinder head surface area, and crankshaft strength, which are all factors that contribute to higher power output.

The angle of the "V" is also important. Common V8 angles are 90 degrees (a very common angle for balanced firing) and less common angles such as 60 or 72 degrees. A 90-degree V8 can be inherently balanced, which reduces the need for complex balancing shafts. The angle is a compromise between size, balance, and manufacturing complexity.

How It Works: The Four-Stroke Cycle

While not unique to V8s, understanding the four-stroke cycle is crucial. Each cylinder goes through these four strokes:

- Intake: The intake valve opens, and the piston moves down, drawing a mixture of air and fuel (or just air in a direct-injection engine) into the cylinder.

- Compression: The intake valve closes, and the piston moves up, compressing the air-fuel mixture.

- Combustion (Power): The spark plug ignites the compressed mixture, creating a powerful explosion that forces the piston down. This is the stroke that produces power.

- Exhaust: The exhaust valve opens, and the piston moves up, pushing the exhaust gases out of the cylinder.

These strokes happen sequentially in each cylinder, but offset from each other according to the firing order. This creates a continuous flow of power from the engine.

Real-World Use: Basic Troubleshooting Tips

Here are some common issues you might encounter with a V8 engine, especially when dealing with older models:

- Misfires: Often caused by faulty spark plugs, ignition coils, or fuel injectors. Check your spark plugs first – they are the easiest to inspect.

- Rough Idle: Can be due to vacuum leaks, a dirty throttle body, or issues with the idle air control (IAC) valve. Inspect vacuum lines for cracks.

- Overheating: Could be caused by a low coolant level, a faulty thermostat, a clogged radiator, or a failing water pump. Never open a hot radiator cap!

- Oil Leaks: Common areas for leaks include the valve covers, oil pan, and crankshaft seals. Check for oil puddles under the engine.

Using the Diagram: Having the diagram handy allows you to visually trace components, understand the relationships between them, and pinpoint potential problem areas. When troubleshooting, start with the most accessible and easily testable components first.

Safety: Handle with Care

Working on a V8 engine involves risks. Here are some key safety precautions:

- Disconnect the Battery: Always disconnect the negative battery cable before starting any electrical work.

- Wear Safety Glasses: Protect your eyes from debris and fluids.

- Use Jack Stands: Never work under a vehicle supported only by a jack.

- Be Careful with Fuel: Fuel is highly flammable. Work in a well-ventilated area and avoid sparks or open flames.

- Hot Surfaces: Be aware that engine components can be extremely hot, even after the engine has been turned off for a while. Allow sufficient time for cooling before touching anything.

- High Pressure: The fuel system can hold residual pressure. Depressurize the system before disconnecting fuel lines.

Remember: If you're unsure about any procedure, consult a qualified mechanic. It's better to be safe than sorry.

Diagram: Your Visual Aid

We've covered a lot of ground, and having a visual reference can make a huge difference. We have a detailed diagram of a generic V8 engine available for you to download. This diagram will help you visualize the layout, component locations, and the flow of fluids within the engine. It will be invaluable for understanding the concepts we discussed and for tackling your own V8 projects.

By understanding the basics of the V8 engine configuration, specifically what the "V" means, you're well on your way to being a more confident and capable DIY mechanic. Remember to take your time, be meticulous, and always prioritize safety. Happy wrenching!