What Does V In V8 Mean

Alright, let's dive into what that "V" really means in a V8 engine. For those of us who wrench on our own cars, or are thinking about getting deeper into engine work, understanding the basic architecture of different engine configurations is absolutely crucial. Knowing why a V8 is designed the way it is will help you diagnose problems, plan modifications, and ultimately, appreciate the engineering that goes into these powerful beasts.

Why This Matters

Understanding the V8 configuration isn't just about bragging rights at the next car meet. It's about being able to diagnose misfires, understand lubrication pathways, and even choose the right performance upgrades. Knowing the layout of the cylinders, the firing order, and how the camshafts interact with the valves is fundamental to any serious engine work.

Moreover, if you're contemplating an engine swap or performance build, grasping the advantages and disadvantages of a V8 layout compared to, say, an inline-four or a V6 is paramount. This knowledge empowers you to make informed decisions and avoid costly mistakes.

Key Specs and Main Parts of a V8 Engine

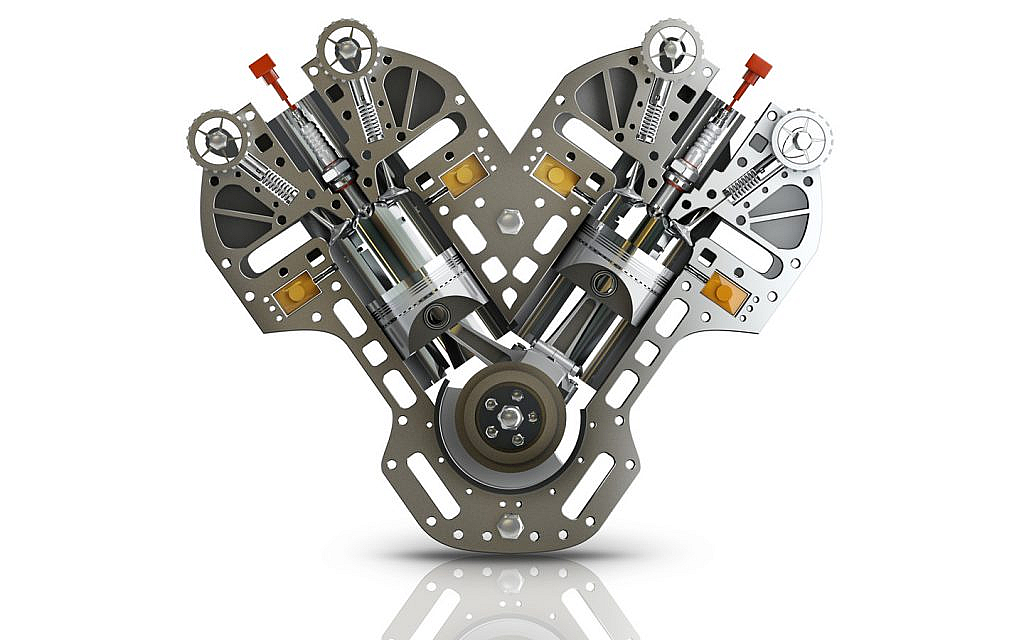

The defining characteristic of a V8 engine is, of course, its eight cylinders arranged in a "V" configuration. This means two banks of four cylinders each, set at an angle to each other. Common V-angles are 90 degrees (often found in American V8s) or narrower angles (like 60 degrees in some European designs).

Main Components:

- Cylinder Block: The foundation of the engine, containing the cylinders and coolant passages. The block's design significantly impacts the engine's strength and cooling efficiency.

- Cylinder Heads: These sit atop the cylinder block and house the intake and exhaust valves, spark plugs, and combustion chambers. Port design in the cylinder heads is crucial for airflow and power output.

- Pistons: Reciprocating components within the cylinders that are driven by the combustion process. Piston design (flat-top, dished, etc.) affects compression ratio and combustion efficiency.

- Connecting Rods: Connect the pistons to the crankshaft, transmitting the force of combustion.

- Crankshaft: Converts the reciprocating motion of the pistons into rotational motion, which is then transmitted to the transmission. The crankshaft's design, including counterweights and journal sizes, impacts engine balance and durability.

- Camshaft(s): Controls the opening and closing of the intake and exhaust valves. Camshaft profile (lift and duration) dramatically affects engine performance characteristics. Some V8s have a single camshaft (pushrod engines), while others have dual overhead camshafts (DOHC) for each cylinder bank.

- Valvetrain: Includes valves, valve springs, lifters (or tappets), pushrods (in pushrod engines), and rocker arms. This system controls the flow of air and fuel into the cylinders and exhaust gases out.

- Intake Manifold: Distributes air (or air/fuel mixture in older carbureted engines) to the cylinders. Intake manifold design influences airflow and power distribution across the RPM range.

- Exhaust Manifold (or Headers): Collects exhaust gases from the cylinders. Exhaust manifold design significantly affects exhaust flow and can influence power output.

Key Specs to consider:

- Displacement: The total volume displaced by all pistons during one stroke, typically measured in cubic inches (ci) or liters (L).

- Compression Ratio: The ratio of the cylinder volume when the piston is at the bottom of its stroke (bottom dead center or BDC) to the cylinder volume when the piston is at the top of its stroke (top dead center or TDC). Higher compression ratios generally lead to increased power and efficiency.

- Bore and Stroke: The bore is the diameter of the cylinder, and the stroke is the distance the piston travels within the cylinder. These dimensions influence engine characteristics like torque and RPM potential.

- Firing Order: The sequence in which the cylinders fire. A well-optimized firing order minimizes vibration and promotes smoother operation.

How It Works

The V8 engine operates on the four-stroke principle: intake, compression, combustion (power), and exhaust. Let's break it down:

- Intake: The intake valve opens, and the piston moves down, creating a vacuum that draws air (or air/fuel mixture) into the cylinder.

- Compression: The intake valve closes, and the piston moves up, compressing the air/fuel mixture.

- Combustion (Power): The spark plug ignites the compressed air/fuel mixture, creating a rapid expansion of gases that forces the piston down. This is the power stroke.

- Exhaust: The exhaust valve opens, and the piston moves up, pushing the exhaust gases out of the cylinder and into the exhaust manifold.

This cycle repeats for each cylinder, timed precisely by the camshaft(s). The "V" configuration allows for a shorter engine block compared to an inline-eight, leading to better packaging and weight distribution. It also allows for the use of a shorter, stiffer crankshaft, improving engine balance and allowing for higher RPMs in some designs.

Real-World Use and Basic Troubleshooting

Understanding the V8's basic operation is essential for troubleshooting common problems. For example:

- Misfires: A misfire occurs when one or more cylinders fail to fire correctly. This can be caused by faulty spark plugs, ignition coils, fuel injectors, or valve problems. To diagnose a misfire, you can use an OBD-II scanner to identify the affected cylinder(s) and then systematically check the components.

- Oil Leaks: Common leak locations include valve cover gaskets, oil pan gaskets, and rear main seals. Identifying the source of the leak is crucial before attempting a repair.

- Overheating: Overheating can be caused by a faulty thermostat, water pump, radiator, or head gasket. Inspecting these components for leaks or damage is essential.

- Low Power: Low power can be caused by a variety of factors, including a clogged air filter, faulty fuel pump, or worn-out engine components. A compression test can help determine the overall health of the engine.

When troubleshooting, always refer to a service manual for your specific vehicle. This will provide detailed instructions and specifications.

Safety Considerations

Working on a V8 engine involves inherent risks. Always disconnect the battery before starting any work to prevent electrical shocks. Be extremely careful when working around the fuel system, as gasoline is highly flammable. Never work under a vehicle supported only by a jack; use jack stands. Wear safety glasses and gloves to protect yourself from fluids and sharp edges. High-pressure fuel injection systems can be dangerous; depressurize the system before disconnecting any fuel lines. Be aware of hot engine components, especially the exhaust manifolds and catalytic converters.

Furthermore, remember that some components, like the timing chain or belt, require specialized tools and knowledge to replace properly. If you're unsure about any procedure, it's always best to consult with a qualified mechanic.

In Conclusion

By understanding the basic architecture, key components, and operational principles of a V8 engine, you'll be better equipped to diagnose problems, perform repairs, and appreciate the engineering that goes into these complex machines. Remember to always prioritize safety and consult a service manual for specific instructions. Happy wrenching!

We have a detailed V8 engine diagram available for download. This diagram includes labeled components, fluid pathways, and wiring schematics. This resource will be invaluable for understanding the inner workings of your V8. Contact us to get access to the diagram file.