What Does V Mean In V8 Engine

Alright, let's talk V8 engines. You've heard the rumble, you've maybe even worked on one. But understanding the "V" in V8 beyond just a configuration is crucial, especially if you're diving into repairs, modifications, or just want a deeper understanding of what's going on under the hood. This isn't just about bragging rights; knowing the layout can save you time diagnosing problems and even prevent costly mistakes.

Purpose: Why This Knowledge Matters

Why bother digging into the specifics of a V8 configuration? Simple. For the intermediate car owner or DIY mechanic, knowing the arrangement and operation of a V8 engine allows for:

- More Accurate Diagnosis: Understanding cylinder banks and firing order helps pinpoint misfires and other performance issues.

- Informed Modifications: Planning performance upgrades like camshafts or exhaust systems requires knowing how the engine is laid out.

- Efficient Repairs: Locating components like spark plugs, fuel injectors, and exhaust manifolds becomes much easier.

- General Knowledge: A deeper understanding of automotive engineering is, well, just plain cool!

Key Specs and Main Parts of a V8

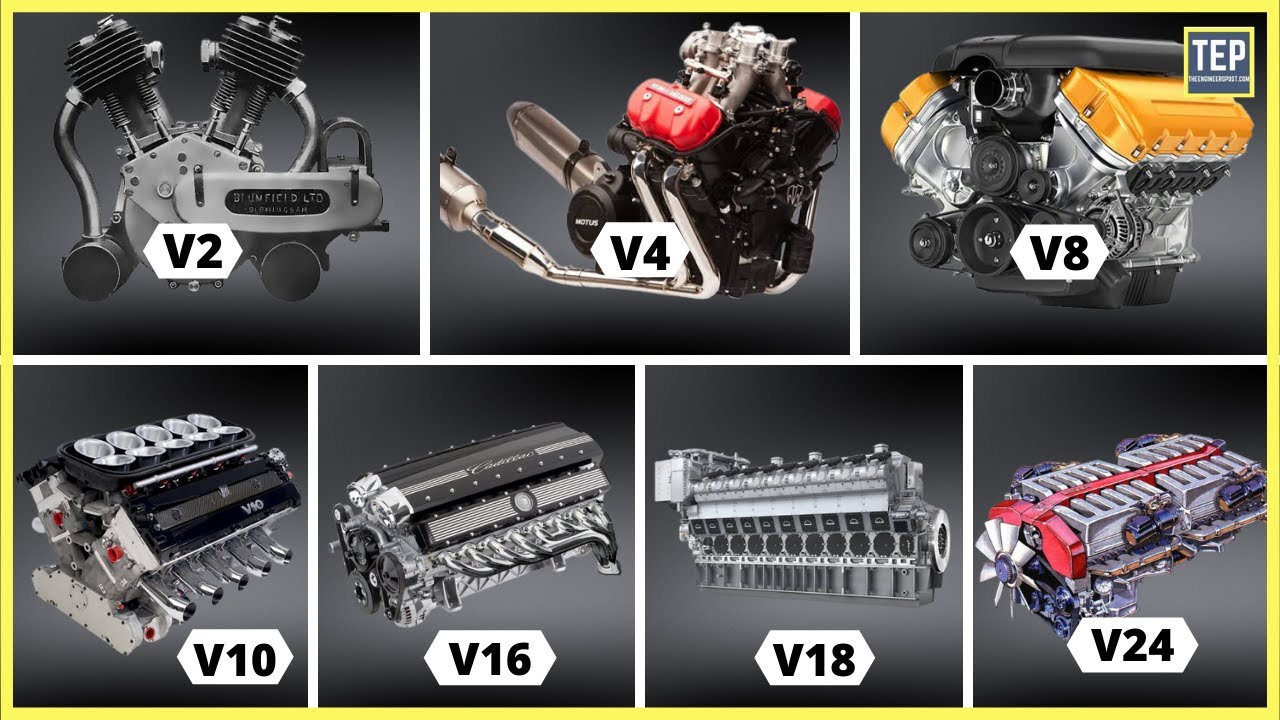

The "V" in V8 refers to the configuration of the cylinders. Instead of a straight line (inline engine) or a horizontally opposed layout (boxer engine), the cylinders are arranged in two banks, forming a "V" shape when viewed from the front or rear of the engine. A V8 engine has eight cylinders, four on each bank.

Key Specifications:

- Bank Angle: The angle between the two cylinder banks. Common angles are 90 degrees (classic V8 design, offering inherent balance), but you'll also find wider and narrower angles depending on the manufacturer's design goals (compactness, performance, etc.). A 90-degree V8 is inherently balanced due to the firing pulses occurring evenly throughout the crankshaft's rotation. Other angles often require balance shafts to mitigate vibrations.

- Firing Order: The sequence in which the cylinders fire. This is critical for smooth engine operation and affects exhaust scavenging. A typical V8 firing order might be 1-8-4-3-6-5-7-2, but it varies by manufacturer.

- Displacement: The total volume displaced by all the pistons as they move from bottom dead center (BDC) to top dead center (TDC). This is often expressed in cubic inches (cu in) or liters (L).

- Bore and Stroke: Bore is the diameter of the cylinder, and stroke is the distance the piston travels within the cylinder. These measurements affect the engine's torque and horsepower characteristics. A "square" engine has roughly equal bore and stroke. Over-square engines (larger bore than stroke) tend to rev higher, while under-square engines (smaller bore than stroke) tend to produce more low-end torque.

Main Parts:

- Cylinder Block: The main structure of the engine, containing the cylinders and coolant passages. V8 blocks are typically made of cast iron or aluminum.

- Cylinder Heads: These sit atop the cylinder block and contain the intake and exhaust valves, spark plugs, and combustion chambers. The design of the cylinder heads significantly impacts the engine's performance.

- Crankshaft: Converts the linear motion of the pistons into rotational motion. The crankshaft's design, including its counterweights, is crucial for engine balance.

- Connecting Rods: Connect the pistons to the crankshaft.

- Pistons: Move up and down within the cylinders, compressing the air-fuel mixture.

- Camshaft: Controls the opening and closing of the intake and exhaust valves. The camshaft's profile (or "lobes") dictates the valve timing, which greatly affects engine performance.

- Intake Manifold: Distributes the air-fuel mixture to the cylinders.

- Exhaust Manifolds/Headers: Collect the exhaust gases from the cylinders and direct them to the exhaust system.

How It Works

The V8 engine operates on the four-stroke cycle: Intake, Compression, Combustion (Power), and Exhaust. Let's break it down:

- Intake: The piston moves down, creating a vacuum. The intake valve opens, allowing the air-fuel mixture (or just air in a direct-injection engine) to enter the cylinder.

- Compression: The intake valve closes, and the piston moves up, compressing the air-fuel mixture.

- Combustion (Power): The spark plug ignites the compressed air-fuel mixture, creating a rapid expansion of gases. This force pushes the piston down, driving the crankshaft.

- Exhaust: The exhaust valve opens, and the piston moves up, pushing the exhaust gases out of the cylinder and into the exhaust manifold.

This cycle repeats for each cylinder, with the crankshaft connecting all pistons to produce continuous rotational power. The firing order ensures that the power strokes are evenly distributed, minimizing vibrations and creating smooth engine operation.

Real-World Use: Basic Troubleshooting Tips

Okay, your V8 isn't running right. Here are a few common issues and how the V-configuration knowledge can help:

- Misfire: A misfire is when a cylinder fails to fire correctly. If you have a check engine light, the OBD-II code will usually identify the misfiring cylinder (e.g., P0301 for cylinder #1). Knowing which bank cylinder #1 is on helps you quickly locate the spark plug, ignition coil, or fuel injector for that cylinder.

- Uneven Exhaust Note: A "puffing" or "popping" sound from one side of the engine might indicate a problem with the exhaust valve or exhaust manifold gasket on that cylinder bank.

- Vibration: Excessive vibration can be caused by a variety of issues, including a damaged harmonic balancer, worn engine mounts, or internal engine damage. Because the engine is comprised of two separate banks, you need to inspect both sides independently, starting by verifying the balance shafts, if the engine is so equipped, and inspecting all the engine mounts on each side.

- Coolant Leak: If you see coolant leaking, knowing the location of the coolant passages in the cylinder block and heads helps you trace the leak to its source.

Pro Tip: Use a stethoscope or a long screwdriver to listen to individual injectors. They should all make a consistent clicking sound. If one is silent or sounds different, it may be faulty.

Safety – Risky Components

Working on a V8 engine can be hazardous. Here are a few key safety considerations:

- Electrical System: The ignition system operates at high voltage. Always disconnect the battery before working on any electrical components, especially the spark plugs or ignition coils.

- Fuel System: Fuel is flammable. Work in a well-ventilated area and avoid sparks or open flames. Depressurize the fuel system before disconnecting any fuel lines.

- Hot Surfaces: The exhaust manifolds and engine block get extremely hot. Allow the engine to cool completely before touching these components.

- Moving Parts: Keep your hands and tools away from moving parts like the crankshaft and camshaft when the engine is running (obviously!).

- Springs & Tension: Valve springs and belt tensioners store a lot of potential energy. Use the correct tools and procedures when working with these components to avoid injury.

Remember, safety first! If you're unsure about any procedure, consult a qualified mechanic or refer to a repair manual.

With a solid understanding of the V8 engine layout and its inner workings, you'll be better equipped to diagnose problems, perform maintenance, and even tackle performance upgrades. Remember to always prioritize safety and consult reliable resources when working on your vehicle.