What Does V8 Mean In Cars

So, you're diving deeper into the heart of your ride and wondering what that "V8" designation really means? You've come to the right place. This article will break down the fundamentals of a V8 engine, focusing on its architecture, operation, and some common troubleshooting scenarios. Consider this your comprehensive guide, from a fellow gearhead to another.

Purpose: Understanding the Powerhouse

Why bother understanding your engine's configuration? Well, knowledge is power, especially when it comes to cars. Understanding the V8 layout is crucial for several reasons:

- Diagnosis and Repair: Knowing the specific components and their locations is essential for accurate diagnosis and efficient repair.

- Performance Tuning: For those looking to boost performance, understanding the engine's architecture allows for informed modifications.

- Preventative Maintenance: Identifying potential weak points and understanding how the engine components function together helps with proactive maintenance.

- General Understanding: You'll gain a deeper appreciation for the engineering marvel that powers your vehicle.

Key Specs and Main Parts of a V8 Engine

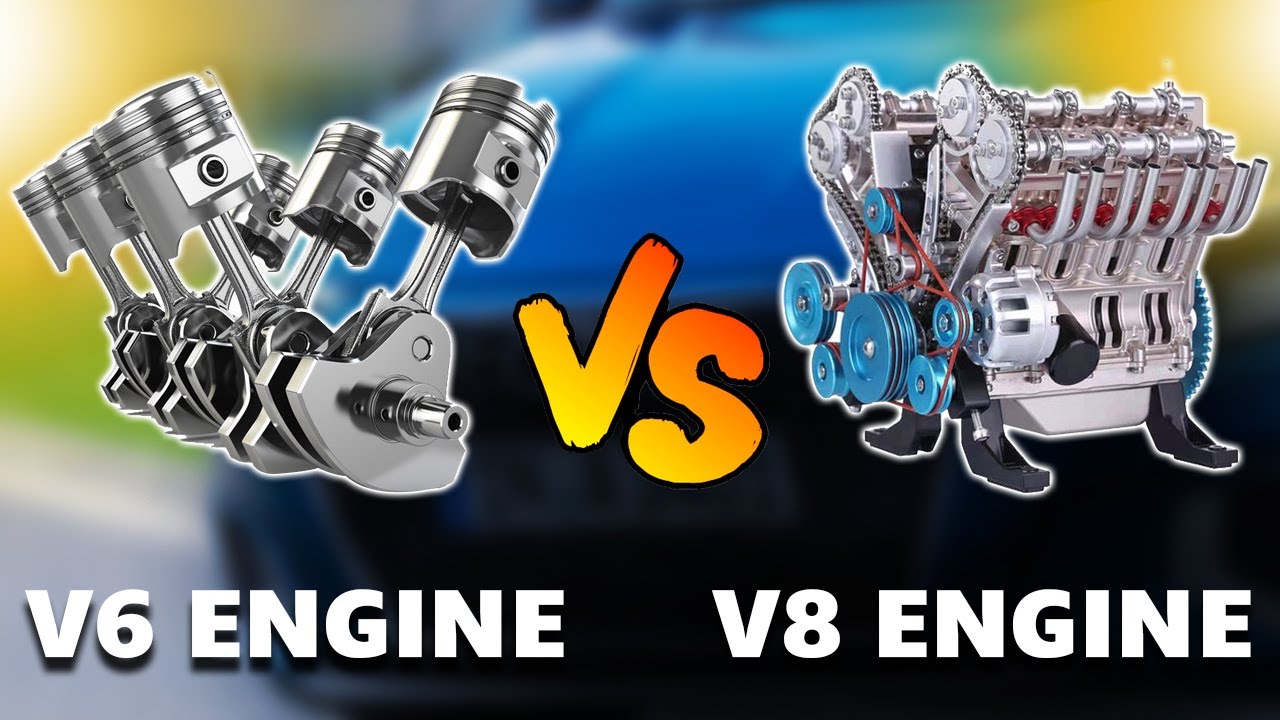

The defining characteristic of a V8 engine is its cylinder arrangement: eight cylinders arranged in a "V" configuration. This design offers a good balance of power, smoothness, and relatively compact size.

Key Specs:

- Cylinder Count: 8

- Configuration: Two banks of 4 cylinders, angled to form a "V". Common angles are 90°, 60°, and 45°. 90° is the most common to offer optimal balance with common firing orders.

- Firing Order: This is the sequence in which the cylinders fire. Common firing orders include 1-8-4-3-6-5-7-2 and 1-5-4-8-6-3-7-2. The firing order plays a crucial role in engine balance and smoothness.

- Displacement: The total volume swept by all the pistons in the cylinders. V8 engines commonly range from around 4.0 liters (244 cubic inches) to over 7.0 liters (427 cubic inches).

- Horsepower and Torque: These figures quantify the engine's power output and rotational force, respectively. V8 engines are known for their high horsepower and torque potential.

Main Parts:

The heart of a V8, like any internal combustion engine, comprises the following critical components:

- Cylinder Block: The foundation of the engine, housing the cylinders, coolant passages, and oil galleries. V8 blocks are typically made of cast iron or aluminum.

- Cylinders: The chambers where combustion occurs.

- Pistons: Move up and down within the cylinders, driven by the combustion process.

- Connecting Rods: Connect the pistons to the crankshaft, converting the reciprocating motion of the pistons into rotational motion.

- Crankshaft: The rotating shaft that converts the linear motion of the pistons into rotational motion, which is then transmitted to the drivetrain.

- Cylinder Heads: Sit atop the cylinder block, containing the valves, spark plugs, and combustion chambers.

- Valves: Control the flow of air and fuel into the cylinders and exhaust gases out.

- Camshaft: Controls the opening and closing of the valves. V8 engines can have one or two camshafts per cylinder bank (Single Overhead Cam - SOHC or Dual Overhead Cam - DOHC).

- Intake Manifold: Distributes air and fuel mixture to the cylinders.

- Exhaust Manifold: Collects exhaust gases from the cylinders and directs them to the exhaust system.

- Fuel System: Supplies fuel to the engine, either through fuel injection or a carburetor (older V8s).

- Ignition System: Provides the spark to ignite the air-fuel mixture in the cylinders.

- Cooling System: Regulates the engine's temperature to prevent overheating.

- Lubrication System: Circulates oil to lubricate and cool the engine's moving parts.

How It Works: The Four-Stroke Cycle

V8 engines, like most internal combustion engines, operate on the four-stroke cycle. Here's a simplified breakdown:

- Intake: The intake valve opens, and the piston moves down, drawing a mixture of air and fuel into the cylinder.

- Compression: The intake valve closes, and the piston moves up, compressing the air-fuel mixture.

- Combustion (Power): The spark plug ignites the compressed air-fuel mixture, causing a rapid expansion of gases that forces the piston down. This is where the engine produces power.

- Exhaust: The exhaust valve opens, and the piston moves up, pushing the exhaust gases out of the cylinder.

This cycle repeats continuously in each cylinder, with each cylinder firing in a specific sequence (the firing order) to create a smooth and powerful engine output. The angled V configuration helps to balance the engine, reducing vibrations and increasing smoothness compared to inline engines with similar cylinder counts.

Real-World Use: Basic Troubleshooting Tips

Alright, let's get practical. Here are some common issues you might encounter with a V8 engine and how to approach them:

- Rough Idling: Could be caused by vacuum leaks, faulty spark plugs, dirty fuel injectors, or a malfunctioning idle air control valve. Start by checking for obvious vacuum leaks and then inspect the spark plugs.

- Loss of Power: Possible causes include a clogged fuel filter, a failing fuel pump, a restricted exhaust system, or low compression in one or more cylinders. Check your fuel pressure and look for any restrictions in the intake or exhaust.

- Engine Knocking (Pinging): Often caused by using low-octane fuel, excessive carbon buildup in the cylinders, or a timing issue. Try using a higher-octane fuel and consider having the engine decarbonized.

- Overheating: Could be due to a coolant leak, a faulty thermostat, a malfunctioning water pump, or a clogged radiator. Check the coolant level and inspect the cooling system for leaks.

- Oil Leaks: Common leak points include valve cover gaskets, oil pan gasket, and crankshaft seals. Visually inspect the engine for oil leaks and replace the affected gaskets or seals.

Important: Always consult your vehicle's repair manual for specific troubleshooting procedures and torque specifications.

Safety: Working Around a V8

Working on a V8 engine can be rewarding, but safety should always be your top priority. Here are some key safety considerations:

- Fuel System: Fuel is highly flammable. Always disconnect the fuel pump fuse or relay before working on the fuel system. Work in a well-ventilated area and avoid sparks or open flames.

- Electrical System: Disconnect the battery's negative terminal before working on the electrical system to prevent accidental shocks or short circuits.

- Hot Surfaces: The exhaust manifold and other engine components can get extremely hot. Allow the engine to cool completely before working on it.

- Moving Parts: Keep your hands and clothing away from moving parts, such as the crankshaft and camshaft, when the engine is running.

- Heavy Components: Cylinder heads and the engine block itself are very heavy. Use proper lifting equipment and techniques to avoid injury.

- Coolant: Coolant is toxic. Avoid skin contact and dispose of properly.

Remember, if you're not comfortable performing a particular repair, it's always best to consult a qualified mechanic. Safety first!

We've put together a detailed diagram of a generic V8 engine layout to aid in your future repairs and learning. This should prove an asset when working on or trying to understand the inner workings of the engine.

You can download the V8 Engine Diagram here: [Link to Diagram] (Diagram file not included in this response, replace with actual link)