What Does V8 Mean On A Car

Alright, let's talk V8 engines. You've seen the badge, heard the rumble, but what does "V8" really mean on a car? It's more than just a marketing term; it's a specific engine configuration with significant implications for performance, fuel economy, and even maintenance. This article will break down the anatomy and operation of a V8 engine, giving you the knowledge to understand its strengths, weaknesses, and how to troubleshoot common issues.

Purpose: Decoding the V8 Engine

Understanding the V8 engine configuration, its components, and its operation is crucial for several reasons, especially if you're a DIY mechanic or someone interested in modifying your car. Knowing the basics of a V8 allows you to:

- Perform Basic Maintenance: Understanding the layout helps you locate components like spark plugs, oil filter, and other essential parts.

- Diagnose Problems: Recognizing symptoms related to specific cylinders or banks of cylinders can greatly improve your troubleshooting accuracy.

- Plan Modifications: Whether you're thinking about adding headers, a new intake manifold, or even forced induction, knowing how the V8 works is essential for making informed decisions.

- Make Informed Purchasing Decisions: When buying a car, understanding the engine type and its potential maintenance costs can help you make a smarter choice.

Key Specs and Main Parts

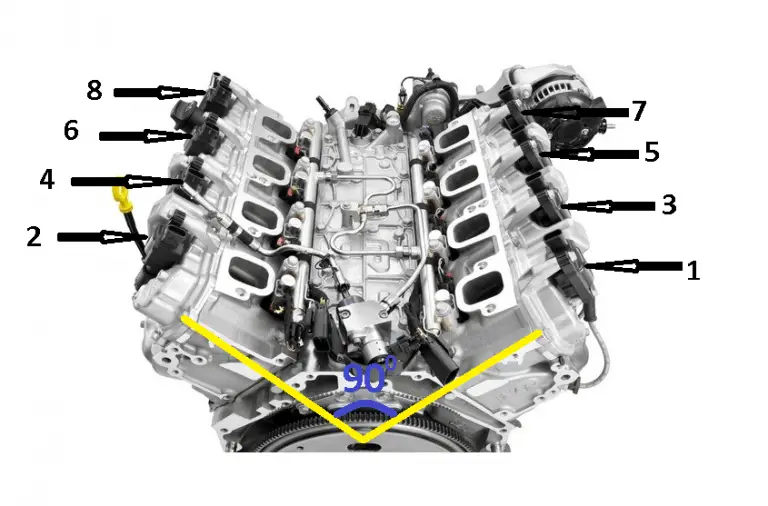

The "V8" designation refers to an 8-cylinder engine where the cylinders are arranged in two banks of four cylinders, forming a "V" shape when viewed from the front or rear of the engine. This configuration offers a good balance of power and smoothness compared to inline engines with fewer cylinders.

Main Components:

- Cylinder Block: The foundation of the engine, containing the cylinders and coolant passages. Typically made of cast iron or aluminum.

- Cylinder Heads: Sit atop the cylinder block and contain the intake and exhaust valves, combustion chambers, and spark plugs. Often made of aluminum for better heat dissipation.

- Pistons: Move up and down within the cylinders, driven by the combustion process. Connected to the connecting rods.

- Connecting Rods: Connect the pistons to the crankshaft. Transfer the piston's motion to rotational motion.

- Crankshaft: A rotating shaft that converts the reciprocating motion of the pistons into rotational motion, which is then transmitted to the transmission.

- Camshaft: Controls the opening and closing of the intake and exhaust valves. Can be located in the block (OHV/pushrod engines) or in the cylinder heads (OHC/DOHC engines).

- Intake Manifold: Distributes the air/fuel mixture (or just air in direct injection engines) to the cylinders.

- Exhaust Manifold (Headers): Collects the exhaust gases from the cylinders and directs them to the exhaust system.

- Valve Train: Includes the valves, springs, rocker arms (in OHV engines), pushrods (in OHV engines), and lifters (or tappets). Controls the timing and duration of valve opening and closing.

- Fuel Injection System: Delivers fuel to the cylinders. Can be port fuel injection (PFI) or direct injection (DI).

- Ignition System: Provides the spark to ignite the air/fuel mixture. Includes the spark plugs, ignition coils, and control module.

Key Specs:

- Displacement: The total volume displaced by all the pistons in the engine, typically measured in cubic inches (ci) or liters (L). A larger displacement generally means more power.

- Compression Ratio: The ratio of the volume of the cylinder when the piston is at the bottom of its stroke to the volume when the piston is at the top of its stroke. Higher compression ratios generally mean more power and efficiency but require higher octane fuel.

- Horsepower: A measure of the engine's power output.

- Torque: A measure of the engine's rotational force.

- Firing Order: The sequence in which the cylinders fire. This is crucial for smooth engine operation and minimizing vibrations.

How It Works: The Four-Stroke Cycle

The vast majority of V8 engines operate on the four-stroke cycle. Each cylinder goes through these four distinct phases:

- Intake: The intake valve opens, and the piston moves down, drawing a mixture of air and fuel (or just air in direct injection engines) into the cylinder.

- Compression: The intake valve closes, and the piston moves up, compressing the air/fuel mixture.

- Combustion (Power): The spark plug ignites the compressed air/fuel mixture, creating a controlled explosion that forces the piston down. This is the power stroke.

- Exhaust: The exhaust valve opens, and the piston moves up, pushing the exhaust gases out of the cylinder and into the exhaust manifold.

Because there are eight cylinders and each cylinder fires on a different part of the cycle, you get much smoother power delivery than with an engine with fewer cylinders. The "V" configuration also allows for a shorter engine length compared to an inline engine with the same number of cylinders.

Real-World Use: Basic Troubleshooting Tips

Here are some common problems you might encounter with a V8 engine and some basic troubleshooting steps:

- Rough Idle: Could be caused by vacuum leaks, faulty spark plugs, dirty fuel injectors, or a malfunctioning idle air control (IAC) valve. Check for vacuum leaks with a spray bottle of soapy water, inspect the spark plugs, and consider cleaning the fuel injectors with an injector cleaner.

- Misfires: Often caused by faulty spark plugs, ignition coils, or fuel injectors. A diagnostic scan tool can help identify which cylinder is misfiring.

- Low Power: Could be caused by a clogged air filter, restricted exhaust, or a failing fuel pump. Check the air filter, inspect the exhaust system for restrictions, and test the fuel pressure.

- Overheating: Could be caused by a low coolant level, a faulty thermostat, a leaking radiator, or a malfunctioning water pump. Check the coolant level, inspect the radiator for leaks, and make sure the thermostat is opening properly.

- Oil Leaks: Common around the valve covers, oil pan, and crankshaft seals. Clean the engine and look for the source of the leak. Often requires replacing gaskets or seals.

Important Note: Always consult a repair manual or a qualified mechanic for complex repairs. Using a diagnostic scan tool can also greatly simplify the troubleshooting process.

Safety: Handle with Care

Working on a V8 engine involves dealing with potentially hazardous components. Always disconnect the battery before working on the electrical system. Be extremely careful when working around the fuel system, as gasoline is highly flammable. Hot exhaust components can cause severe burns, so allow the engine to cool down before working on the exhaust system.

Specifically, pay extra attention to:

- Fuel Lines: Pressurized fuel can spray if lines are disconnected improperly. Depressurize the fuel system before disconnecting any lines.

- Exhaust Manifold: Can remain extremely hot for a long time after the engine is turned off. Wear heat-resistant gloves.

- Electrical System: High voltage is present in the ignition system. Always disconnect the battery before working on the electrical system.

- Rotating Parts: Keep hands and clothing away from moving parts like the crankshaft, camshaft, and accessory drive belts when the engine is running.

Remember, safety is paramount. If you're unsure about any procedure, consult a qualified mechanic.

This article provides a solid foundation for understanding V8 engines. With the right knowledge and tools, you can confidently tackle many common maintenance and repair tasks.