What Engine Does The Gtr Have

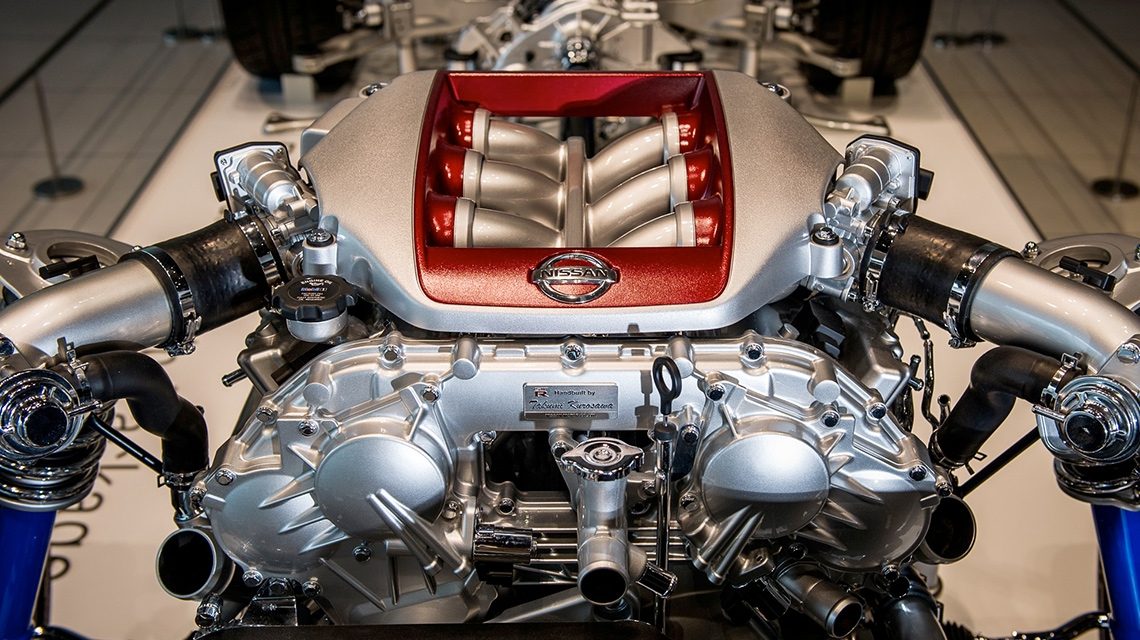

Alright gearheads, let's dive deep into the heart of the Nissan GT-R and talk about the engine that makes it the legendary "Godzilla" we all know and love: the VR38DETT. Understanding this engine is crucial whether you're planning on some DIY maintenance, considering modifications, or just want to appreciate the engineering marvel that sits under that sculpted hood. We'll break down the key components, how they work together, and even touch on some common issues. Plus, for those who want to go even further, we've got the full engine diagram available for download – link will be provided at the end!

Why Understanding the VR38DETT Matters

Why bother learning about the intricacies of this engine? Well, a solid understanding of your engine empowers you in several ways:

- Informed Maintenance: Knowing the engine layout and components helps you diagnose problems more accurately, perform routine maintenance more effectively, and identify potential issues before they become major headaches.

- Smarter Modifications: Thinking about adding more boost or upgrading components? Understanding how the engine works allows you to make informed decisions about which modifications will yield the best results and avoid costly mistakes.

- General Appreciation: Let's be honest, the VR38DETT is a technological masterpiece. Understanding its complexities adds to your appreciation of the GT-R as a whole.

Key Specs and Main Parts

Let's get down to the nitty-gritty. The VR38DETT is a 3.8-liter (3799cc) 60-degree V6, twin-turbocharged engine. Here's a rundown of the key specs:

- Configuration: V6, 60-degree angle

- Displacement: 3.8 liters (3799 cc)

- Aspiration: Twin-turbocharged

- Valve Train: DOHC, 4 valves per cylinder (24 valves total)

- Bore x Stroke: 95.5 mm x 88.4 mm

- Compression Ratio: Varies by year/model, generally around 9.0:1

- Fuel Delivery: Sequential multi-point fuel injection

Now, let's identify the main parts we'll be focusing on:

- Engine Block: The foundation of the engine, housing the crankshaft, pistons, and connecting rods. The VR38DETT block is made of cast aluminum alloy.

- Cylinder Heads: Located atop the engine block, containing the valves, camshafts, and spark plugs. These are also made of aluminum alloy.

- Crankshaft: Converts the linear motion of the pistons into rotational motion. It's made of forged steel for strength and durability.

- Pistons & Connecting Rods: The pistons move up and down within the cylinders, driven by the combustion process, and connect to the crankshaft via connecting rods.

- Camshafts: Control the opening and closing of the intake and exhaust valves. The VR38DETT uses Dual Overhead Camshafts (DOHC) for precise valve timing.

- Turbochargers: Forced induction devices that compress intake air, increasing the amount of oxygen entering the cylinders and boosting power output. The VR38DETT uses two IHI turbochargers.

- Intercoolers: Cool the compressed air from the turbochargers before it enters the engine, increasing its density and further improving power.

- Fuel Injectors: Spray fuel into the intake ports for combustion. The VR38DETT uses high-flow injectors to meet the engine's fuel demands.

- ECU (Engine Control Unit): The "brain" of the engine, controlling various parameters such as fuel injection, ignition timing, and boost pressure.

Visualizing the Components

Think of the engine block as the sturdy base of a building. The crankshaft is the central rotating component, like the axle in a wheel. The pistons are pushed up and down by explosions, turning that wheel. The cylinder heads sit on top, managing the airflow (air and exhaust) like the roof controls the ventilation. The turbos act like super-powered fans forcing more air in, and the ECU is the architect, making sure everything works in harmony.

How It Works

The VR38DETT operates on the standard four-stroke combustion cycle: Intake, Compression, Combustion (Power), and Exhaust. Let's walk through each stage:

- Intake: The intake valve opens, and the piston moves down, creating a vacuum that draws air into the cylinder. The air is measured by the MAF (Mass Airflow) sensor.

- Compression: The intake valve closes, and the piston moves up, compressing the air-fuel mixture. The fuel is sprayed into the intake port by the fuel injectors.

- Combustion (Power): The spark plug ignites the compressed air-fuel mixture, creating an explosion that forces the piston down. This is the power stroke that turns the crankshaft.

- Exhaust: The exhaust valve opens, and the piston moves up, pushing the exhaust gases out of the cylinder and into the exhaust manifold, through the turbochargers, and finally out the exhaust system.

The twin-turbochargers significantly enhance this process. They compress the intake air, forcing more air into the cylinders than would naturally occur. This allows the engine to burn more fuel and produce more power. The intercoolers then cool this compressed air, further increasing its density and power potential.

Real-World Use – Basic Troubleshooting

Okay, so you've got the basics down. Now, what if something goes wrong? Here are a few common issues and troubleshooting tips:

- Loss of Power: Could be a variety of things, including a faulty turbocharger, a clogged air filter, a bad mass airflow sensor, or even a simple vacuum leak. Check for any unusual noises or smells. Start with the easy things first like air filter.

- Check Engine Light: The dreaded CEL! Use an OBD-II scanner to retrieve the diagnostic trouble code (DTC). Research the code to determine the potential cause. Common culprits include faulty oxygen sensors, misfires, or issues with the fuel system.

- Rough Idling: Could be caused by a vacuum leak, dirty fuel injectors, or a faulty ignition coil.

- Excessive Oil Consumption: Potential causes include worn piston rings, leaky valve stem seals, or turbocharger issues.

Important Note: These are just basic troubleshooting tips. Always consult a qualified mechanic for complex issues. When diagnosing, it's best to start with the most accessible and least expensive components first.

Safety – Highlight Risky Components

Working on the VR38DETT requires caution, as with any high-performance engine. Here are a few areas to pay particular attention to:

- High-Pressure Fuel System: The fuel injectors and fuel lines operate under high pressure. Always relieve the pressure before disconnecting any fuel system components.

- Electrical System: Disconnect the battery before working on any electrical components. Short circuits can be dangerous and damage sensitive electronic components.

- Turbochargers: Turbochargers get extremely hot during operation. Allow them to cool down completely before handling them. The exhaust manifolds are also scalding hot.

- Sharp Edges: Be mindful of sharp edges on engine components and use appropriate protective gear, such as gloves.

- Hot Fluids: Coolant and oil can be extremely hot. Allow the engine to cool down before draining these fluids.

- Torque Specs: Always use a torque wrench and adhere to the specified torque values when tightening bolts. Over-tightening or under-tightening can lead to component failure.

Remember: Safety should always be your top priority. If you're unsure about any procedure, consult a qualified mechanic.

We've covered a lot of ground here, from the basic specs of the VR38DETT to some common troubleshooting tips. This should give you a solid foundation for understanding this incredible engine.

Now, as promised, we have the full engine diagram available for download. This detailed diagram includes exploded views of all the major components, part numbers, and other useful information. It's a valuable resource for anyone planning on working on their GT-R.

Happy wrenching! (But be safe!)