What Engine Fits In My Car

So, you're thinking about an engine swap, a serious repair, or just want to understand your car's guts a little better? Figuring out exactly what engine fits in your car isn't as simple as just measuring the space and slapping something in. There are a ton of factors involved, from mounting points to electrical compatibility. This article will guide you through understanding the diagrams and specifications you need to make informed decisions. We'll break down the key elements, so you can approach your project with confidence, whether it's a full-blown modification or a simpler repair.

Purpose: Decoding Engine Compatibility

Why bother diving into these engine diagrams and specs? The answer is multifaceted:

- Repairs and Replacements: When your engine finally gives up the ghost, knowing compatible replacement engines is crucial. You don't want to buy an engine only to find it doesn't bolt up or communicate with your car's computer.

- Performance Upgrades (Engine Swaps): Swapping in a more powerful or modern engine can drastically improve performance. However, this is a complex undertaking that requires meticulous planning and a deep understanding of engine compatibility.

- Learning and Understanding: Even if you aren't planning a major project, understanding the intricacies of your engine compartment and engine specifications is a great way to deepen your mechanical knowledge.

- Troubleshooting: Diagrams are invaluable for pinpointing components and tracing electrical circuits when diagnosing engine problems.

Key Specs and Main Parts

Before you even look at a diagram, you need to grasp some essential engine specifications. These will be the starting points when determining compatibility:

- Engine Family/Code: This is the engine's unique identifier (e.g., "GM LS3," "Toyota 2JZ-GTE"). This code tells you everything about the engine's design, displacement, and intended application.

- Displacement: Measured in liters (L) or cubic inches (CID), displacement indicates the total volume swept by all the pistons inside the cylinders. Bigger displacement generally means more power, but also increased fuel consumption.

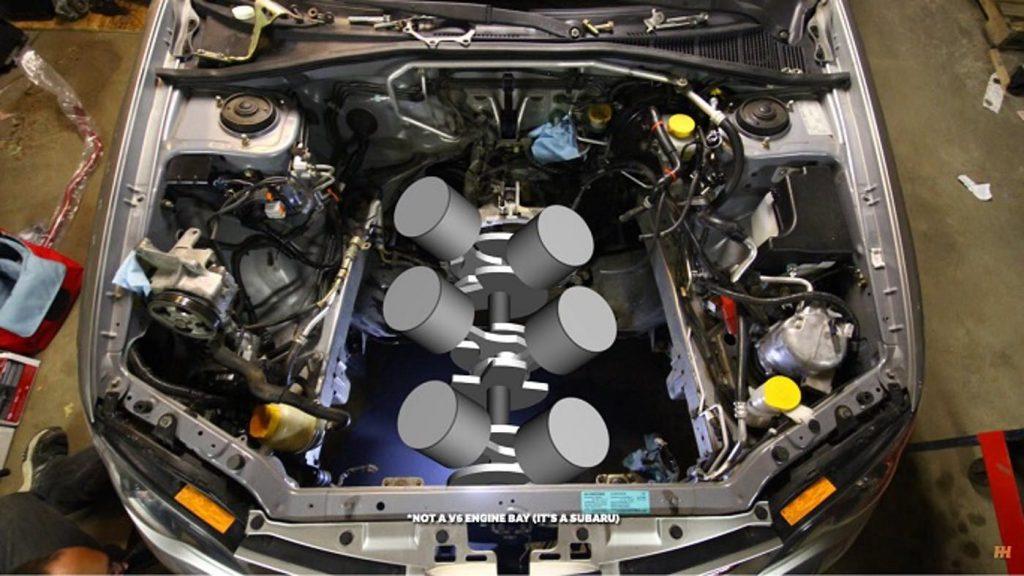

- Engine Configuration: Inline (I), V-shaped (V), or horizontally opposed (Boxer) configurations determine the engine's physical shape and impact its fitment.

- Mounting Points: The location and design of the engine mounts must align with your car's chassis. This is often the biggest hurdle in engine swaps.

- Transmission Compatibility: Will your existing transmission bolt up to the new engine? What about the driveshaft? You'll need to research this carefully.

- Fuel System: Is the engine designed for fuel injection (EFI) or a carburetor? Your car’s fuel system will need to be compatible or modified.

- Electrical System: Engine management systems (EMS) are complex. You'll need to consider the compatibility of the engine's wiring harness, sensors, and computer (ECU) with your car's electrical system. This is probably the trickiest aspect of swaps.

- Exhaust System: The engine's exhaust manifold design will influence how easily it connects to your car's existing exhaust system.

Main engine components you will typically find referenced in a diagram:

- Cylinder Block: The engine's foundation, containing the cylinders.

- Cylinder Head: Sits atop the cylinder block, containing the valves and combustion chambers.

- Pistons: Move up and down within the cylinders, driven by combustion.

- Connecting Rods: Connect the pistons to the crankshaft.

- Crankshaft: Converts the linear motion of the pistons into rotary motion.

- Camshaft(s): Controls the opening and closing of the valves.

- Intake Manifold: Distributes air to the cylinders.

- Exhaust Manifold: Collects exhaust gases from the cylinders.

- Sensors: Monitor various engine parameters (e.g., temperature, pressure, oxygen levels).

- ECU (Engine Control Unit): The engine's "brain," controlling fuel injection, ignition timing, and other critical functions.

Symbols: Reading the Engine Diagram Language

Engine diagrams use a variety of symbols to represent different components and connections. Understanding these symbols is crucial for interpreting the diagram correctly.

- Lines:

- Solid Lines: Typically represent fluid lines (fuel, oil, coolant) or mechanical linkages.

- Dashed Lines: Usually indicate vacuum lines or electrical wiring. The thickness of the dashed line might differentiate between low-current and high-current wiring.

- Dotted Lines: Often represent control lines or signals.

- Colors: Colors in wiring diagrams are standardized. For example, red is usually power (12V), black is ground, and other colors indicate specific signals. Always refer to the diagram's color key.

- Icons: Icons represent specific components like sensors, actuators, valves, and pumps. Common icons include:

- Resistors: A zig-zag line.

- Capacitors: Two parallel lines.

- Diodes: A triangle pointing to a line.

- Sensors: Often represented by a circle with a symbol inside indicating what it measures (e.g., temperature sensor, pressure sensor).

- Actuators (e.g., injectors, solenoids): May be represented by a rectangle with a specific symbol inside.

- Numerical Values: Diagrams often include numerical values indicating wire gauge (thickness), voltage, pressure, or resistance.

Always consult the diagram's legend or key to understand the specific symbols and conventions used in that particular diagram.

How It Works: Putting It All Together

Engine diagrams are essentially visual representations of the engine's systems. They show how the various components are connected and how they interact with each other.

For example, a fuel system diagram will show the fuel tank, fuel pump, fuel filter, fuel lines, fuel rail, fuel injectors, and fuel pressure regulator. It will also show the electrical connections to the fuel pump and injectors. By tracing the lines and symbols, you can understand how fuel flows from the tank to the engine and how the ECU controls fuel delivery.

Similarly, an electrical wiring diagram will show all the wiring harnesses, connectors, sensors, actuators, and the ECU. By following the lines and noting the wire colors, you can trace electrical circuits and identify potential faults.

Real-World Use: Basic Troubleshooting Tips

Here's how you can use engine diagrams for troubleshooting:

- Identify the Problem Component: Use the diagram to locate the component you suspect is faulty.

- Trace the Circuit: Follow the wiring diagram to trace the circuit connected to the component. Look for breaks in the wiring, corroded connectors, or short circuits.

- Check Sensor Readings: Use the diagram to identify the location of sensors and check their readings with a scan tool or multimeter. Compare the readings to the specifications in the service manual.

- Test Actuators: Use the diagram to identify the wiring to actuators (e.g., fuel injectors, solenoids) and test their functionality by applying voltage or using a scan tool to activate them.

- Verify Grounds: Many electrical problems are caused by poor grounds. Use the diagram to locate ground points and ensure they are clean and properly connected.

Safety: Handling Risky Components

Engines contain several potentially dangerous components:

- Fuel System: Fuel is highly flammable. Always disconnect the fuel pump and relieve fuel pressure before working on the fuel system. Work in a well-ventilated area and avoid sparks or open flames.

- Electrical System: High voltage components, such as the ignition coils, can deliver a dangerous shock. Disconnect the battery before working on the electrical system.

- Exhaust System: Exhaust gases are toxic. Always work in a well-ventilated area and avoid breathing exhaust fumes. Exhaust systems can also be extremely hot.

- Rotating Parts: Never work on a running engine with loose clothing or jewelry that could get caught in rotating parts like belts or pulleys.

- High Pressure Fluids: The oil and coolant systems operate under pressure. Allow the engine to cool down before opening these systems to prevent burns.

Always consult the service manual for your specific vehicle for detailed safety precautions.

Understanding engine diagrams is a vital skill for any serious DIY mechanic or modder. While engine swaps and major repairs can be complex, a solid grasp of the engine's systems, coupled with accurate diagrams, will help you approach these projects with confidence and safety. We have the file, and you can download the diagram to start your project.