What Engine Is In The Nissan Gtr

Alright, let's dive deep into the heart of the Nissan GT-R and uncover the secrets of its legendary engine. Knowing the ins and outs of this powerplant is crucial, whether you're planning on performing routine maintenance, diagnosing a pesky problem, or even contemplating some serious performance upgrades. This isn't just about knowing what engine is in there; it's about understanding how it works, why it's designed the way it is, and how to keep it running strong.

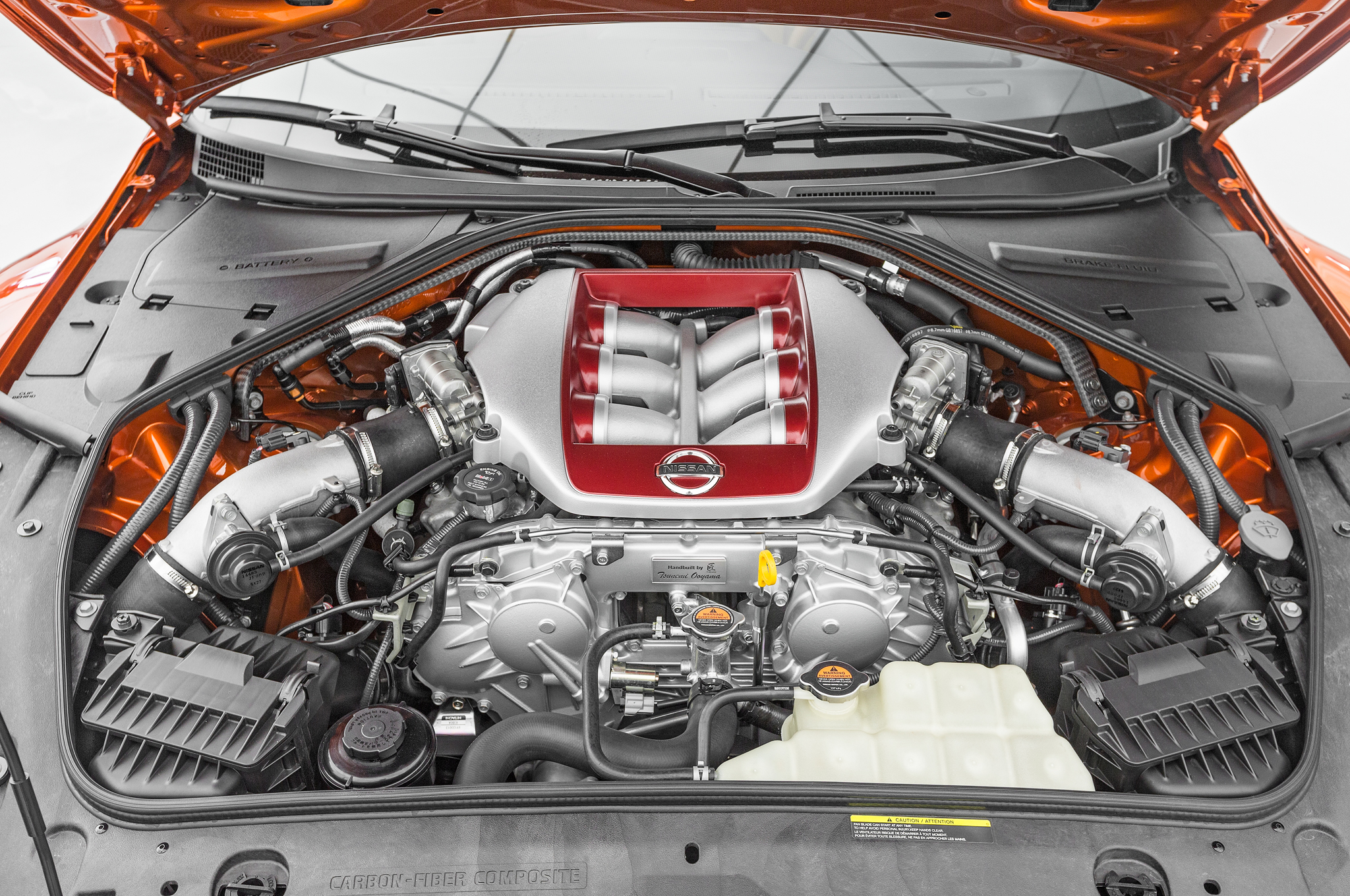

The VR38DETT: A Technical Overview

The engine powering the Nissan GT-R is the VR38DETT. This is more than just a name; it tells you a lot about the engine's configuration. Let's break it down:

- VR: This indicates a V-shaped engine block with a narrow angle between the cylinder banks (approximately 60 degrees). The "R" further designates it as a racing-derived engine.

- 38: This denotes the engine's displacement, which is approximately 3.8 liters.

- DE: These letters signify Dual Overhead Camshafts. This means there are two camshafts per cylinder bank, one for intake valves and one for exhaust valves.

- TT: This indicates that the engine is Twin-Turbocharged.

Key Specs and Main Parts

Here's a rundown of the critical specifications that define the VR38DETT:

- Configuration: V6, Twin-Turbocharged

- Displacement: 3.8 liters (3799 cc)

- Bore x Stroke: 95.5 mm x 88.4 mm

- Compression Ratio: Varies depending on the model year, but typically around 9.0:1

- Valve Train: DOHC, 4 valves per cylinder (24 valves total)

- Fuel Delivery: Electronic Fuel Injection (EFI)

- Turbochargers: IHI Turbochargers (Model varies depending on year)

- Intercoolers: Air-to-Air

- Horsepower: Varies by year and tune, ranging from around 480 hp to over 600 hp in factory trims, and significantly higher with aftermarket modifications.

- Torque: Similar to horsepower, torque figures vary, but generally fall in the range of 430-480 lb-ft.

Now, let's look at the main components that make the VR38DETT tick:

- Cylinder Block: Typically cast aluminum alloy, providing a lightweight yet strong foundation for the engine.

- Cylinder Heads: Aluminum alloy, housing the valves, camshafts, and fuel injectors.

- Crankshaft: Forged steel, converting the reciprocating motion of the pistons into rotational power.

- Connecting Rods: High-strength steel, connecting the pistons to the crankshaft.

- Pistons: Forged aluminum alloy, moving up and down within the cylinders to compress the air-fuel mixture.

- Camshafts: Controlling the opening and closing of the intake and exhaust valves.

- Turbochargers: Forced induction devices that compress the intake air, increasing engine power.

- Intercoolers: Cooling the compressed air from the turbochargers before it enters the engine, further increasing power.

- Fuel Injectors: Precisely metering and injecting fuel into the cylinders.

- Engine Control Unit (ECU): The "brain" of the engine, controlling fuel injection, ignition timing, and other critical parameters.

How It Works

The VR38DETT operates on the four-stroke principle: Intake, Compression, Combustion, and Exhaust. Let's walk through each step:

- Intake: The piston moves down, creating a vacuum in the cylinder. The intake valve opens, allowing air to be drawn into the cylinder. The turbochargers significantly increase the amount of air entering the cylinder, which is then cooled by the intercoolers.

- Compression: The intake valve closes, and the piston moves up, compressing the air-fuel mixture. This compression increases the mixture's temperature, making it more readily combustible.

- Combustion: At the peak of compression, the spark plug ignites the air-fuel mixture, causing a rapid expansion of gases. This expansion pushes the piston down, generating power.

- Exhaust: The exhaust valve opens, and the piston moves up, pushing the burnt gases out of the cylinder and into the exhaust system.

The twin-turbocharger system is a crucial element in the VR38DETT's performance. Each turbocharger is dedicated to one bank of cylinders, providing a more responsive and efficient boost. The intercoolers play a vital role in cooling the compressed air, as cooler air is denser and contains more oxygen, leading to more power.

Real-World Use – Basic Troubleshooting Tips

Here are a few common issues you might encounter with the VR38DETT and some initial troubleshooting steps:

- Reduced Power/Turbo Lag: Check for boost leaks in the turbocharger system. Inspect the intercooler piping, turbocharger hoses, and wastegate actuators. A faulty boost sensor can also cause this issue.

- Rough Idle/Misfires: Check the spark plugs, ignition coils, and fuel injectors. A vacuum leak can also contribute to rough idling. Scan for diagnostic trouble codes (DTCs) using an OBD-II scanner.

- Overheating: Check the coolant level, radiator, thermostat, and water pump. A blown head gasket can also cause overheating.

- Oil Leaks: The VR38DETT can be prone to oil leaks, especially around the valve covers, oil pan, and turbocharger lines. Regularly inspect these areas for leaks.

Important Note: Many VR38DETT issues require specialized diagnostic tools and expertise. If you're not comfortable working on complex engine components, it's best to consult a qualified mechanic.

Safety – Highlight Risky Components

Working on the VR38DETT involves inherent risks due to the high pressures, temperatures, and electrical voltages involved. Here are some key safety considerations:

- Fuel System: The fuel system operates under high pressure. Always relieve fuel pressure before disconnecting any fuel lines or components. Gasoline is highly flammable, so exercise extreme caution when working around fuel.

- Turbocharger System: The turbochargers operate at extremely high temperatures. Allow the engine to cool down completely before working on the turbocharger system.

- Electrical System: The ignition system generates high voltages. Disconnect the battery before working on any electrical components.

- Exhaust System: The exhaust system gets extremely hot. Allow the engine to cool down completely before working on the exhaust system.

Wear appropriate safety gear, including safety glasses, gloves, and protective clothing. Always follow the manufacturer's recommendations and procedures when performing any maintenance or repairs.

Having access to a detailed engine diagram is invaluable for performing maintenance, repairs, and upgrades. The diagram provides a visual representation of the engine's components and their relationships. You can use it to identify parts, trace circuits, and understand the engine's overall layout.

We have a high-resolution diagram of the VR38DETT available for download. This diagram includes detailed illustrations of the engine's components, wiring harnesses, and fluid lines. This resource will be invaluable for your repairs and modifications.