What Fuel Do Electric Cars Run On

Alright, let's talk about what "fuel" powers your electric car. It's not gasoline, obviously, but it's not magic either. Understanding the flow of energy in an electric vehicle (EV) is crucial, whether you're planning some basic maintenance, diagnosing a charging issue, or even contemplating more advanced modifications. We'll break down the core components and how they work together.

Electric Vehicle "Fuel": More Than Just Electrons

Technically, the "fuel" is electricity, but it's the storage and delivery of that electricity that makes an EV function. Think of it like this: gasoline is the fuel for an internal combustion engine, but the fuel pump, lines, and injectors are just as important. We're going to explore the EV equivalent of that.

Key Specs and Main Parts

Here's a breakdown of the essential components, consider this a quick reference before we deep dive:

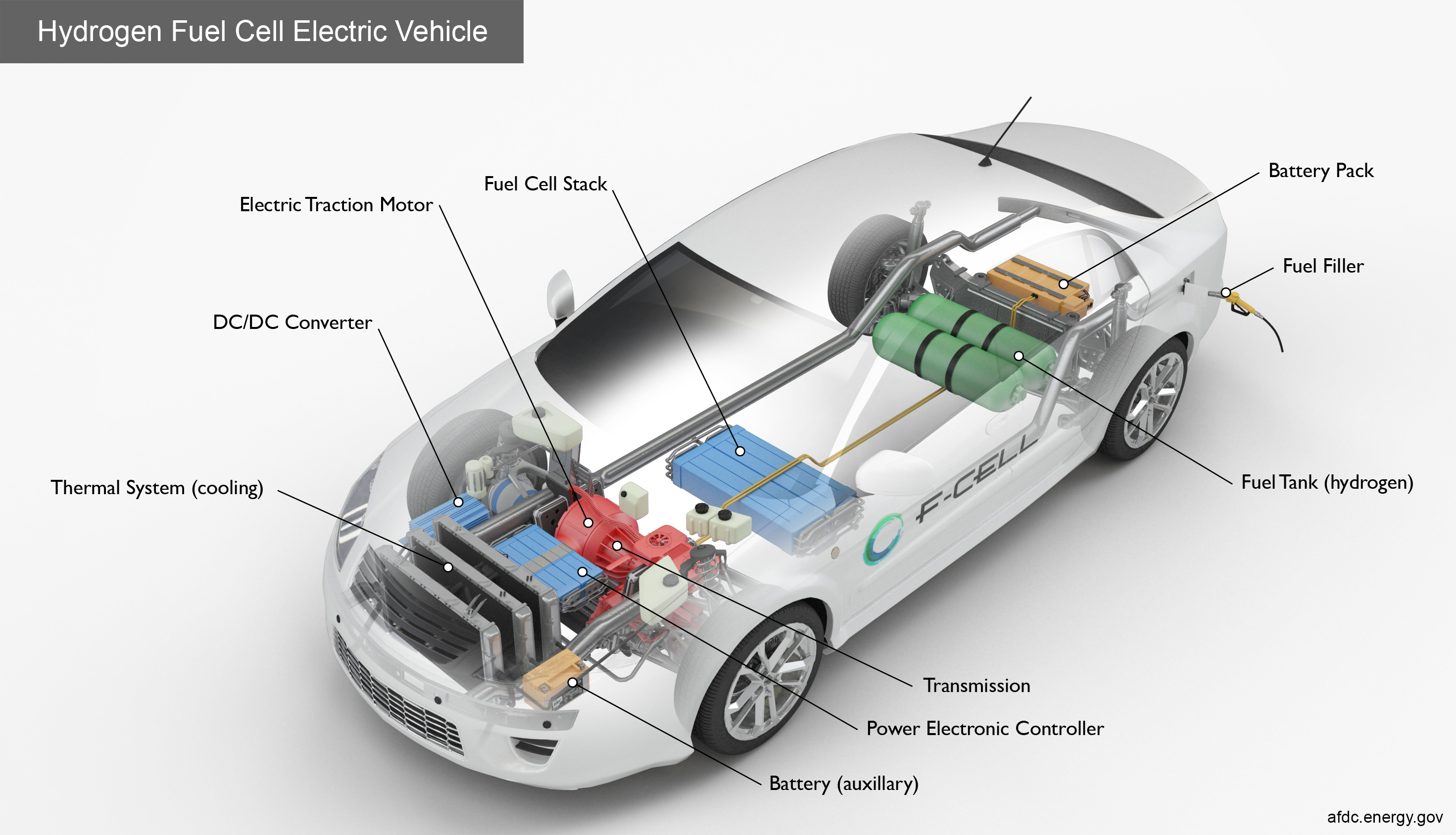

- Battery Pack: The heart of the system, storing the DC (Direct Current) electricity. Key specs include voltage (V), capacity (kWh - kilowatt-hours), and C-rate (charge/discharge rate).

- Battery Management System (BMS): Critically important. This electronic control unit monitors the battery's state of charge (SOC), state of health (SOH), temperature, and voltage of individual cells, preventing overcharging, over-discharging, and thermal runaway.

- Onboard Charger (OBC): Converts AC (Alternating Current) electricity from a wall outlet or charging station into DC electricity suitable for charging the battery. Its power rating (kW) determines charging speed.

- DC-DC Converter: Steps down the high-voltage DC from the battery to a lower voltage (typically 12V) to power auxiliary systems like lights, infotainment, and other electronics – just like in a regular car.

- Traction Inverter: Converts DC electricity from the battery into AC electricity that drives the electric motor(s).

- Electric Motor(s): Convert electrical energy into mechanical energy, turning the wheels. Key specs include power (kW or hp) and torque (Nm or lb-ft).

- Thermal Management System: Cools or heats the battery pack, motor(s), and other components to maintain optimal operating temperature and prolong lifespan.

- Charging Port: The physical interface for connecting to AC or DC charging stations.

Understanding the Symbols and Connections

Visualizing the energy flow requires understanding the symbols used in EV schematics. While standardization isn't perfect, here are some common conventions:

- Solid Lines: Typically represent high-voltage DC power circuits. The thicker the line, the higher the current capacity.

- Dashed Lines: Often indicate communication or control signals between components (e.g., CAN bus).

- Thin Lines: Usually represent low-voltage DC circuits (e.g., 12V system).

- Colors:

- Orange: Universally indicates high-voltage circuits. Exercise extreme caution!

- Red: Positive (+) DC voltage.

- Black: Negative (-) DC voltage or ground.

- Blue/White: Communication lines (CAN, Ethernet, etc.).

- Icons: You'll see standard electrical symbols for resistors, capacitors, inductors, diodes, and transistors within the internal circuits of the BMS, OBC, and inverter. Knowing these symbols is fundamental to understanding the finer details of the control systems.

How It Works: From Plug to Motion

Let's trace the path of energy from the charging station to the wheels:

- Charging (AC): When you plug into an AC charging station, the AC electricity flows through the charging port to the onboard charger (OBC). The OBC converts the AC to DC and regulates the voltage and current to safely charge the battery pack. The BMS constantly monitors the battery's condition during charging.

- Charging (DC Fast Charging): With DC fast charging, the AC-to-DC conversion happens *outside* the car, in the charging station itself. The DC electricity is then fed directly into the battery pack, bypassing the OBC. This allows for much faster charging rates. The BMS still plays a critical role in overseeing the charging process.

- Battery Power: The battery pack stores the DC electricity at a high voltage (typically 400V or 800V).

- Powering the Motor: When you accelerate, the BMS signals the traction inverter to draw power from the battery. The inverter converts the DC electricity into AC electricity of the appropriate voltage and frequency to control the speed and torque of the electric motor(s).

- Auxiliary Systems: The DC-DC converter steps down the high-voltage DC from the battery to 12V to power the car's lights, infotainment system, climate control, and other accessories.

- Regenerative Braking: When you decelerate, the electric motor acts as a generator, converting kinetic energy back into electrical energy and feeding it back into the battery pack. This helps to recapture some of the energy that would otherwise be lost as heat during braking, improving efficiency.

Real-World Use: Basic Troubleshooting Tips

Even without specialized tools, you can perform some basic troubleshooting:

- Charging Issues: If your car isn't charging, first check the charging cable and the charging port for any damage or debris. Try a different charging station. If the problem persists, it could be a faulty OBC or a BMS issue. Consult a qualified technician.

- Reduced Range: A significant drop in range could indicate a degradation of the battery pack's capacity. Check your car's software for battery health diagnostics. Extreme temperatures can also temporarily affect range.

- Warning Lights: Pay attention to any warning lights on the dashboard. Refer to your owner's manual to understand their meaning. Never ignore a high-voltage warning light.

Note: Most EV repairs require specialized equipment and training. Don't attempt to work on high-voltage components unless you are properly qualified and equipped.

Safety First: High-Voltage Hazards

High-voltage systems are extremely dangerous and can be lethal. Always take the following precautions:

- Never work on high-voltage components unless you are properly trained and have the appropriate personal protective equipment (PPE), including high-voltage gloves and eye protection.

- Always disconnect the high-voltage battery before performing any maintenance or repairs. Follow the manufacturer's recommended procedure for disconnecting the battery, including waiting the specified amount of time for the capacitors to discharge.

- Use a CAT III or CAT IV multimeter to verify that the high-voltage system is de-energized before touching any components.

- Be aware of the potential for arc flash, which can occur when working with high-voltage systems.

- If you are not comfortable working on high-voltage systems, leave it to a qualified technician.

The battery pack, inverter, and all the orange-cabled components are potentially lethal if mishandled. Understand your limits and prioritize safety. Incorrect handling can cause severe burns, electrocution, or even death. If you're unsure, seek professional help. It's always better to be safe than sorry.

This article gives you a foundational understanding of the energy flow in an EV. For a more detailed view, including specific component schematics and wiring diagrams, we have a detailed diagram available for download. This diagram provides a more in-depth look at the different circuits and components within the EV's powertrain. This will let you go further in your EV projects. It provides a deeper understanding than what we've gone over here. Click here to access the complete EV energy flow diagram.