What Is A 2 Litre Engine

Alright, let's dive into the heart of many modern vehicles: the 2-liter engine. This isn't just about knowing what size it is; it's about understanding its fundamental design and how it translates to performance and potential issues. Understanding this foundational aspect empowers you for repairs, modifications, and informed decision-making when choosing or maintaining a vehicle. We'll break down the key components, operational principles, and even touch on some common troubleshooting tips. I'm writing this as if you're already comfortable wrenching on cars and just want to deepen your understanding.

Key Specs and Main Parts of a 2-Liter Engine

The term "2-liter" refers to the engine's displacement. Displacement, measured in liters (L) or cubic centimeters (cc), indicates the total volume swept by all the pistons inside the cylinders during one complete engine cycle. A 2-liter engine displaces 2,000 cc, often written as 2000 cm3. This displacement is calculated based on the bore (cylinder diameter) and stroke (distance the piston travels) of each cylinder, multiplied by the number of cylinders. Most 2-liter engines are inline-4 cylinder engines, but you can find some V6 configurations as well. Regardless of configuration, all cylinders combined equal that 2-Liter volume.

Here's a breakdown of the critical parts:

- Cylinder Block: The foundation of the engine, containing the cylinders where combustion occurs. It's typically made of cast iron or aluminum.

- Cylinder Head: Sits atop the cylinder block, sealing the cylinders and housing the valves, camshaft(s), and combustion chambers. Aluminum is the dominant material.

- Pistons: Move up and down within the cylinders, driven by the expanding gases produced during combustion. They are connected to the connecting rods.

- Connecting Rods: Connect the pistons to the crankshaft, transferring the reciprocating motion of the pistons into rotational motion of the crankshaft.

- Crankshaft: A rotating shaft that converts the linear motion of the pistons into rotational motion, which drives the transmission and ultimately the wheels.

- Valves (Intake & Exhaust): Control the flow of air/fuel mixture into the cylinders (intake) and the expulsion of exhaust gases (exhaust).

- Camshaft(s): Controls the opening and closing of the valves, synchronized with the crankshaft. Many modern engines have two (DOHC - Dual Overhead Camshaft) for better valve control.

- Timing Belt/Chain: Connects the crankshaft and camshaft(s), ensuring they are synchronized. Failure of this component can be catastrophic.

- Intake Manifold: Distributes the air/fuel mixture to the cylinders.

- Exhaust Manifold: Collects exhaust gases from the cylinders and directs them to the exhaust system.

- Fuel Injectors: Spray fuel into the intake manifold or directly into the cylinders (direct injection).

- Spark Plugs: Ignite the air/fuel mixture in the cylinders (for gasoline engines). Diesel engines rely on compression ignition.

- Oil Pan: Sits at the bottom of the engine, holding the engine oil.

- Water Pump: Circulates coolant through the engine to regulate temperature.

How It Works: The Four-Stroke Cycle

Most 2-liter engines operate on the four-stroke cycle, also known as the Otto cycle (for gasoline engines):

- Intake: The intake valve opens, and the piston moves down, drawing the air/fuel mixture into the cylinder.

- Compression: The intake valve closes, and the piston moves up, compressing the air/fuel mixture. This compression heats the mixture, making it easier to ignite.

- Combustion: The spark plug ignites the compressed air/fuel mixture. The rapidly expanding gases force the piston down.

- Exhaust: The exhaust valve opens, and the piston moves up, pushing the burnt gases out of the cylinder.

This cycle repeats continuously, converting chemical energy (fuel) into mechanical energy (rotation of the crankshaft).

Real-World Use: Basic Troubleshooting Tips

Here are a few basic troubleshooting tips related to common 2-liter engine problems:

- Rough Idling or Stalling: Could be caused by vacuum leaks, faulty spark plugs, dirty fuel injectors, or a malfunctioning mass airflow (MAF) sensor.

- Loss of Power: Could be due to a clogged air filter, failing fuel pump, worn spark plugs, or a restricted exhaust system (e.g., a clogged catalytic converter).

- Overheating: Could be caused by a low coolant level, a faulty thermostat, a failing water pump, or a radiator blockage.

- Check Engine Light (CEL): This can indicate a wide range of problems, from minor issues to serious malfunctions. Use an OBD-II scanner to retrieve the trouble codes and research the potential causes.

- Oil Leaks: Common areas for leaks include the valve cover gasket, oil pan gasket, and crankshaft seals.

Always start with the simplest and most obvious potential causes before moving on to more complex diagnostics. Also, always use the correct diagnostic tools and follow the manufacturer's recommended procedures.

Safety Considerations

Working on an engine can be dangerous. Here are some key safety points:

- High Voltage: The ignition system produces high voltage. Always disconnect the battery before working on any electrical components.

- Hot Surfaces: The engine and exhaust system get extremely hot. Allow the engine to cool completely before working on it.

- Flammable Fluids: Gasoline and other fluids are highly flammable. Work in a well-ventilated area and avoid sparks or open flames.

- Moving Parts: Keep your hands and clothing away from moving parts, especially when the engine is running. Never run the engine with the timing belt/chain cover removed unless absolutely necessary for diagnostics, and then only with extreme caution.

- Lifting Heavy Components: Use proper lifting equipment (e.g., engine hoist) when removing heavy components like the engine or cylinder head.

The timing belt or chain is a particularly risky component. If it breaks, it can cause severe engine damage, especially on interference engines (where the valves and pistons can collide). Regular inspection and replacement are critical.

Closing Thoughts

Understanding the fundamentals of a 2-liter engine, including its key components and how it operates, is crucial for informed vehicle ownership and maintenance. This knowledge allows you to perform basic troubleshooting, communicate effectively with mechanics, and make informed decisions about repairs and modifications. Remember to always prioritize safety when working on your vehicle and consult a qualified mechanic when in doubt.

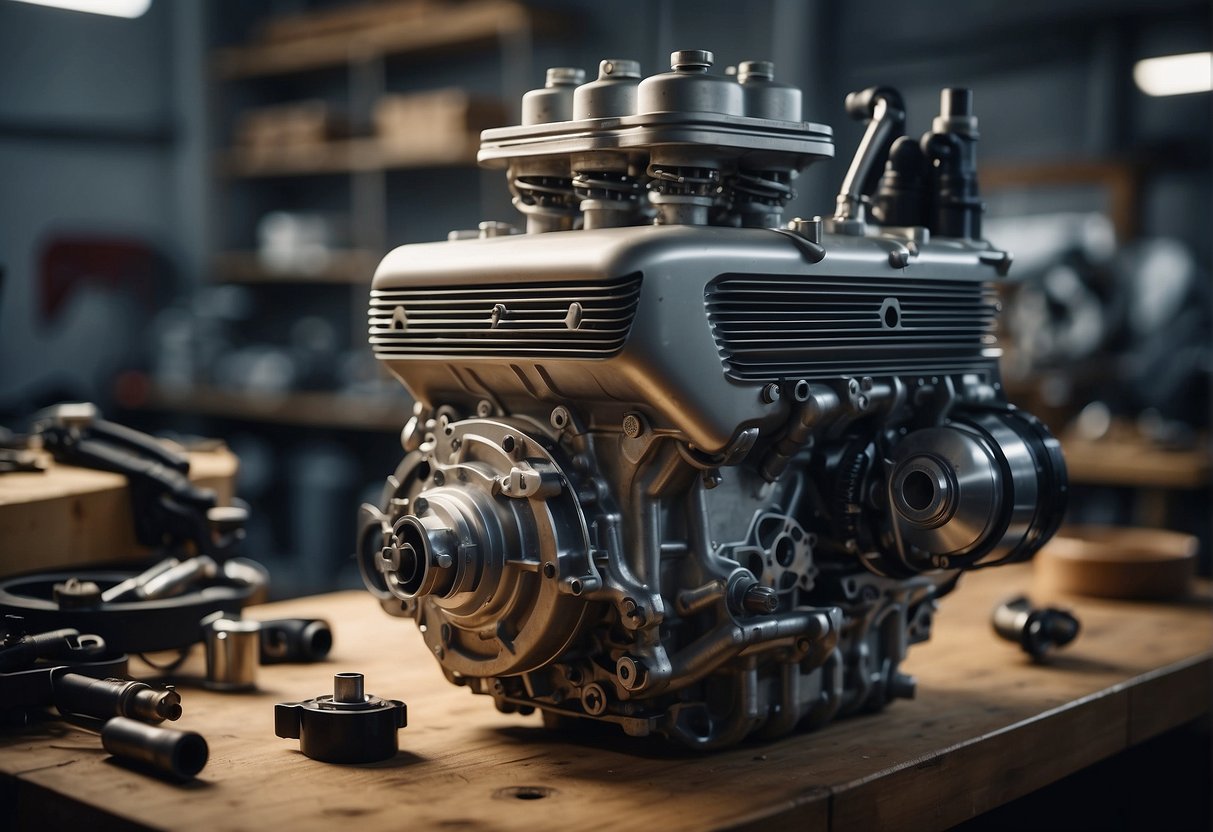

To further assist your learning and repair endeavors, we have prepared a detailed 2-liter engine diagram. This diagram contains intricate details of each component, their connection points, and specifications. You can download this diagram for future reference by using the link on the main page.