What Is A 3 Cylinder Engine

So, you're curious about 3-cylinder engines, huh? Excellent choice. These little powerhouses are becoming increasingly common, offering a blend of fuel efficiency and surprising performance. This deep dive will give you a solid understanding of how they work, their strengths, and how to keep them running smoothly. Consider this your comprehensive guide.

Why This Matters: Understanding the 3-Cylinder Engine

Why bother learning about 3-cylinder engines? Whether you're planning on modifying your car, performing basic maintenance, or just want to understand the technology under the hood, knowing the ins and outs of your engine is crucial. Specifically, understanding the 3-cylinder design can help you diagnose issues more effectively, appreciate its fuel-saving design, and even make informed decisions about performance upgrades. Plus, with their growing popularity, familiarity with these engines is becoming increasingly valuable for any serious DIY mechanic or car enthusiast. We’ll cover everything from the key components to troubleshooting common problems, giving you the knowledge and confidence to tackle any 3-cylinder challenge.

Key Specs and Main Parts

At its core, a 3-cylinder engine is an internal combustion engine with – you guessed it – three cylinders. Here’s a breakdown of the key components:

- Cylinder Block: The foundation of the engine, housing the cylinders. It's typically made of cast iron or aluminum.

- Cylinders: The chambers where combustion takes place. Each cylinder contains a piston.

- Pistons: Reciprocating components that move up and down within the cylinders, driven by the force of combustion. They are connected to the connecting rods.

- Connecting Rods: These rods connect the pistons to the crankshaft.

- Crankshaft: A rotating shaft that converts the linear motion of the pistons into rotational motion, which ultimately drives the wheels.

- Cylinder Head: Sits atop the cylinder block, containing the intake and exhaust valves, as well as the combustion chambers.

- Intake Valves: Control the flow of air and fuel mixture into the cylinders.

- Exhaust Valves: Control the flow of exhaust gases out of the cylinders.

- Camshaft: A rotating shaft with lobes that operate the intake and exhaust valves.

- Timing Belt/Chain: Connects the crankshaft to the camshaft, ensuring that the valves open and close at the correct time relative to the piston's position.

- Fuel Injectors: Spray fuel into the intake manifold or directly into the cylinders.

- Spark Plugs: Ignite the air-fuel mixture in the cylinders.

- Engine Control Unit (ECU): The "brain" of the engine, controlling various parameters such as fuel injection, ignition timing, and idle speed.

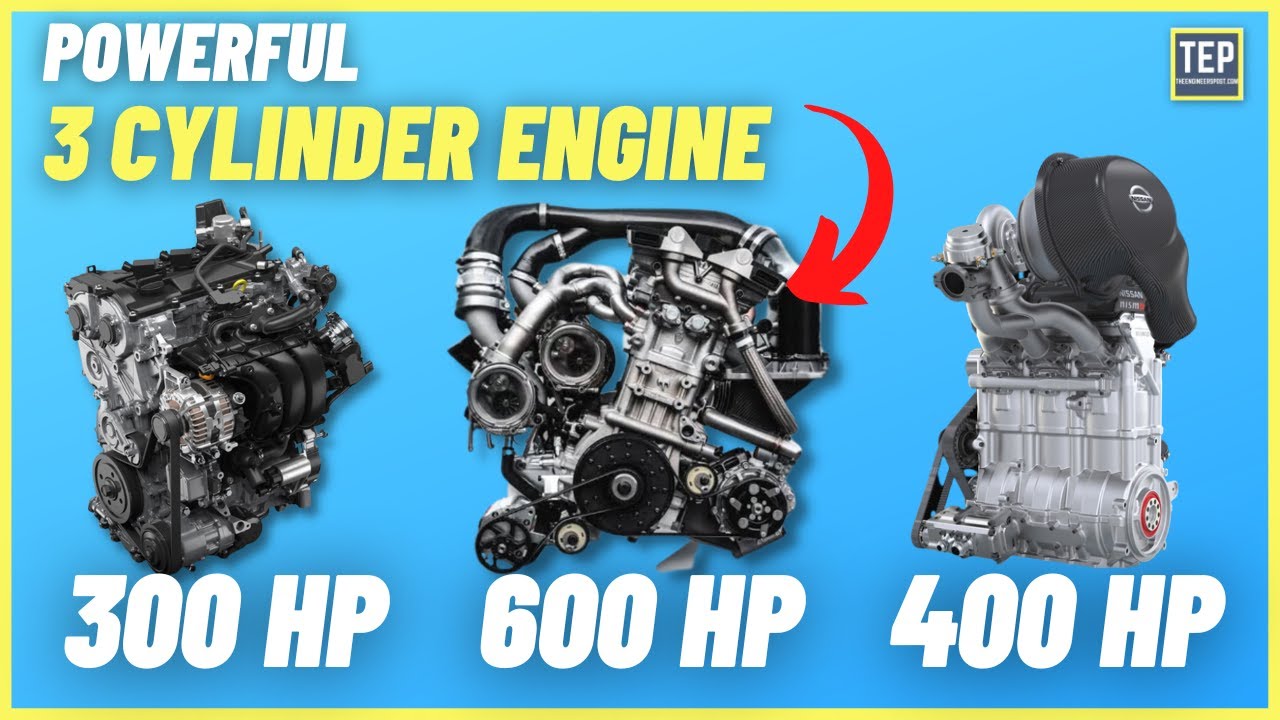

- Turbocharger (Optional): Many modern 3-cylinder engines are turbocharged to boost power output. It forces more air into the cylinders, increasing the amount of fuel that can be burned.

Key Specs to Consider:

- Displacement: The total volume swept by all the pistons in the engine (usually measured in liters or cubic centimeters). Typical 3-cylinder displacements range from 0.8L to 1.5L.

- Bore and Stroke: The bore is the diameter of the cylinder, and the stroke is the distance the piston travels within the cylinder. These measurements affect the engine's characteristics, such as its torque and power output.

- Compression Ratio: The ratio of the volume of the cylinder when the piston is at the bottom of its stroke to the volume when the piston is at the top of its stroke. Higher compression ratios generally lead to better fuel efficiency and power.

- Horsepower and Torque: Horsepower is a measure of the engine's power output, while torque is a measure of its rotational force.

How It Works: The Four-Stroke Cycle

The 3-cylinder engine, like most internal combustion engines, operates on the four-stroke cycle:

- Intake: The piston moves down, creating a vacuum in the cylinder. The intake valve opens, and the air-fuel mixture is drawn into the cylinder.

- Compression: The intake valve closes, and the piston moves up, compressing the air-fuel mixture.

- Combustion (Power): The spark plug ignites the compressed air-fuel mixture, creating a rapid expansion of gases that forces the piston down. This is the power stroke.

- Exhaust: The exhaust valve opens, and the piston moves up, pushing the exhaust gases out of the cylinder.

Because there are only three cylinders, the firing order is different from a 4-cylinder engine. The most common firing order is 1-2-3 or 1-3-2, ensuring balanced operation and minimizing vibrations (although inherent imbalance is a characteristic of 3-cylinder designs).

Real-World Use and Basic Troubleshooting

While 3-cylinder engines are generally reliable, they can experience issues. Here are a few common problems and how to diagnose them:

- Rough Idling: Could be caused by a faulty spark plug, fuel injector, or vacuum leak. Check spark plug condition and resistance, listen for hissing sounds indicating vacuum leaks, and consider using a fuel injector cleaner.

- Loss of Power: Possible causes include a clogged air filter, a faulty mass airflow (MAF) sensor, or a problem with the turbocharger (if equipped). Inspect the air filter, clean the MAF sensor (carefully!), and check the turbocharger's boost pressure.

- Poor Fuel Economy: Can be due to a variety of factors, including a faulty oxygen sensor, a leaking fuel injector, or excessive idling. Check the oxygen sensor's voltage output, inspect the fuel injectors for leaks, and reduce unnecessary idling.

- Excessive Vibration: Inherent to the design, but excessive vibration could indicate a worn engine mount or a problem with the crankshaft damper. Inspect the engine mounts for cracks or damage, and check the crankshaft damper for wear or looseness.

Important Note: Many modern 3-cylinder engines use direct fuel injection (GDI), which can lead to carbon buildup on the intake valves. This can cause performance issues and reduced fuel economy. Consider using a fuel system cleaner specifically designed for GDI engines.

Safety: Components to Handle with Care

Working on any engine involves inherent risks. Here are a few components to be particularly careful with when working on a 3-cylinder engine:

- Fuel System: Depressurize the fuel system before disconnecting any fuel lines or injectors. Gasoline is highly flammable. Always disconnect the negative battery terminal before working on the fuel system.

- Electrical System: Disconnect the negative battery terminal before working on any electrical components. Short circuits can damage the ECU and other sensitive electronics.

- Turbocharger: Turbochargers can get extremely hot. Allow the engine to cool down completely before working on the turbocharger or its related components.

- Cooling System: Never remove the radiator cap while the engine is hot. The cooling system is pressurized, and hot coolant can spray out, causing serious burns.

- Timing Belt/Chain: If you're replacing the timing belt or chain, be sure to follow the manufacturer's instructions carefully. Incorrect timing can cause serious engine damage. Lock the cams and crank before disassembly.

Always wear safety glasses and gloves when working on your engine, and consult the vehicle's service manual for specific instructions and torque specifications.

Conclusion

Understanding the intricacies of a 3-cylinder engine opens doors to better maintenance, troubleshooting, and even performance modifications. With its balance of fuel efficiency and surprising power, the 3-cylinder design is a relevant choice. Remember to prioritize safety and always consult the vehicle's service manual for specific instructions. Happy wrenching!