What Is A 4 Wheel Drive

Alright, let's dive into the world of 4 Wheel Drive (4WD). This isn't just about slapping a sticker on your ride; it's a complex system that can significantly enhance your vehicle's capability. Whether you're contemplating upgrading your current setup, troubleshooting a pesky issue, or simply want a deeper understanding, grasping the intricacies of a 4WD system is crucial. This article is designed to give you, an experienced DIYer or intermediate car owner, a thorough overview. We'll break down the components, explain the functionality, and even touch upon some common problems and safety considerations. We also have a detailed diagram available for download, which will be invaluable for repairs or in-depth study.

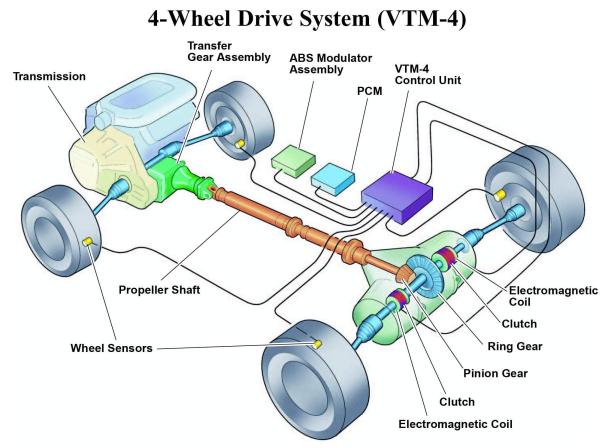

Key Specs and Main Parts

Before we get into the nitty-gritty, let's lay out the foundational components of a typical 4WD system. These parts work together to distribute power to all four wheels, improving traction and control, especially in challenging terrains.

- Engine: While not exclusive to 4WD, the engine provides the initial power that drives the entire system.

- Transmission: This crucial component manages the engine's power and torque, sending it onward to the transfer case. Key specs here include gear ratios, which directly impact the amount of torque available at the wheels.

- Transfer Case: This is the heart of the 4WD system. It splits the power from the transmission and sends it to both the front and rear axles. It also typically contains low-range gearing for increased torque at lower speeds, crucial for off-roading. Different types exist, including part-time, full-time, and automatic transfer cases.

- Driveshafts: These rotating tubes transmit power from the transfer case to the front and rear differentials. They need to be strong enough to handle the considerable torque, especially in low range.

- Differentials (Front and Rear): A differential allows each wheel on an axle to spin at different speeds, which is necessary when turning. However, in low-traction situations, a standard differential can send all power to the wheel with the least resistance (the spinning wheel), negating the benefits of 4WD. This is where optional locking differentials or limited-slip differentials come into play.

- Axles: These shafts transmit power from the differential to the wheels themselves.

- Hubs: These connect the wheels to the axles. Some systems use manually locking hubs, requiring you to physically lock them in for 4WD engagement. Others use automatic hubs that engage when 4WD is selected.

- Control System: This includes levers, buttons, or electronic controls that allow the driver to engage and disengage 4WD, and sometimes to select different modes like 4-High or 4-Low.

Symbols and Lines in 4WD Diagrams

Understanding the symbols used in 4WD diagrams is crucial for interpreting schematics and troubleshooting effectively. The diagram we have available for download uses industry-standard conventions:

- Solid Lines: These typically represent mechanical connections, such as the driveshafts, axles, and linkages.

- Dashed Lines: These often represent electrical connections, vacuum lines, or hydraulic lines associated with the 4WD system.

- Arrows: Indicate the direction of power flow.

- Gears: Depict gear sets within the transmission, transfer case, and differentials. The number of teeth on each gear may be indicated.

- Rectangles: Often represent components like the transfer case or differentials.

- Circles: Can represent shafts, bearings, or other rotating components.

- Switches and Actuators: Represent the electronic or mechanical components that control the engagement and disengagement of 4WD.

- Colors: Sometimes, colors are used to differentiate between different subsystems or types of fluid (e.g., red for transmission fluid, blue for brake fluid – although this is less common in purely mechanical diagrams).

The specific key for the diagram we've prepared will provide more detailed explanations of the symbols used.

How It Works

The basic principle of 4WD is simple: distribute power to all four wheels to improve traction. However, the execution is more complex. Here's a breakdown of how a typical part-time 4WD system functions:

- Normal Operation (2WD): In 2WD mode, power flows from the engine to the transmission, and then exclusively to the rear axle through the driveshaft and differential. The front axle is typically disconnected or idling.

- 4WD Engagement: When the driver selects 4WD, the transfer case engages. This mechanically links the front and rear driveshafts. Now, power is split between both axles. Typically, a 50/50 split, though this can vary.

- 4-High: This mode provides increased traction for situations like snow-covered roads or light off-roading. The gear ratios remain the same as in 2WD, offering a balance of speed and traction.

- 4-Low: This mode engages a low-range gear set within the transfer case. This drastically increases the torque output to the wheels, allowing for slow, controlled movement over challenging terrain like rocks or deep mud. This is where you'll feel the most significant increase in pulling power. However, 4-Low is not intended for high-speed use.

- Differentials and Traction: As mentioned earlier, standard differentials allow wheels to spin at different speeds. In 4WD, this means that if one wheel loses traction, it can spin freely, robbing power from the other wheels. Locking differentials or limited-slip differentials help to mitigate this by limiting the amount of slippage between wheels on the same axle. A locking differential can completely lock both wheels together, forcing them to spin at the same speed, regardless of traction.

Real-World Use and Basic Troubleshooting

Understanding the theory is one thing, but applying that knowledge in the real world is where it truly becomes valuable. Here are some basic troubleshooting tips for common 4WD issues:

- Difficulty Engaging 4WD: This could be due to a number of factors, including a malfunctioning shift linkage, a faulty vacuum actuator, or a problem with the electronic control system. Check the fuses and wiring related to the 4WD system. Sticking linkages are also a common culprit, especially if the system isn't used regularly. Try rocking the vehicle back and forth while attempting to engage 4WD.

- Grinding Noises: Grinding sounds when engaging 4WD often indicate worn synchronizers in the transfer case or damaged gears. Immediate inspection is needed to prevent further damage.

- Vibrations: Vibrations, especially at higher speeds in 4WD, can be caused by worn U-joints in the driveshafts, an unbalanced driveshaft, or incorrect driveline angles (especially after lifting a vehicle).

- 4WD Disengages Unexpectedly: This could be due to a slipping transfer case chain, a faulty actuator, or an electrical issue.

- Uneven Tire Wear: Using 4WD on dry pavement can cause excessive stress on the drivetrain and lead to uneven tire wear. Only use 4WD when necessary, such as on slippery surfaces.

Safety Considerations

Working on a 4WD system can be risky if proper precautions aren't taken. Here are some key safety points to remember:

- Driveline Angles: Modifying a vehicle's suspension (e.g., lifting it) can significantly alter the driveline angles. This can lead to excessive stress on the U-joints, vibrations, and premature failure. Ensure that driveline angles are within acceptable limits after any suspension modifications.

- High Torque Components: The components in a 4WD system are subjected to very high torque loads. Always use appropriate tools and torque specifications when working on these components.

- Potential Energy Storage: Springs and suspension components store significant potential energy. Use spring compressors safely and never work under a vehicle supported only by a jack. Always use jack stands.

- Fluid Leaks: Be aware of potential fluid leaks (transmission fluid, gear oil) when working on the drivetrain. Wear appropriate personal protective equipment (PPE), such as gloves and eye protection.

- Proper Disconnection: Before working on any part of the drivetrain, ensure the vehicle is properly supported, the parking brake is engaged, and the wheels are chocked. Disconnect the negative battery cable to prevent accidental starting.

- Differentials: When working with differentials, be aware of the backlash and preload settings. Incorrectly adjusting these can lead to premature wear or failure.

Remember, working on a 4WD system requires a good understanding of mechanical principles and proper safety procedures. If you're unsure about any aspect of the repair, consult a qualified mechanic.

To further aid your understanding and repair endeavors, we have a detailed 4WD system diagram available for download. This diagram will provide a visual representation of the components and their relationships, making troubleshooting and repairs much easier. You can access the download link [Insert Download Link Here]. This resource, combined with the information presented here, should provide you with a solid foundation for understanding and working on 4WD systems.