What Is A 6 Cylinder Engine

So, you're ready to dive a little deeper into the heart of your machine, huh? Excellent. Today, we're going to dissect the venerable 6-cylinder engine. Whether you're planning a rebuild, chasing down a persistent misfire, or simply want to understand what makes your car tick, knowing the ins and outs of this engine configuration is invaluable. Think of this as your expert guide – the kind you'd get from your trusted mechanic (that's me!), tailored for the experienced DIYer.

Why This Matters: The 6-Cylinder Engine Deconstructed

Understanding your engine beyond just knowing its horsepower figures is crucial. This deep dive provides practical benefits:

- Troubleshooting: Pinpoint problems faster by understanding component interactions.

- Repairing: Confidently tackle repairs with a clear picture of the engine's anatomy.

- Modifying: Make informed decisions about performance upgrades and compatibility.

- Maintenance: Perform preventative maintenance more effectively.

- Knowledge: Enhance your overall automotive expertise and appreciate the engineering marvel that powers your ride.

Key Specs and Main Parts of a 6-Cylinder Engine

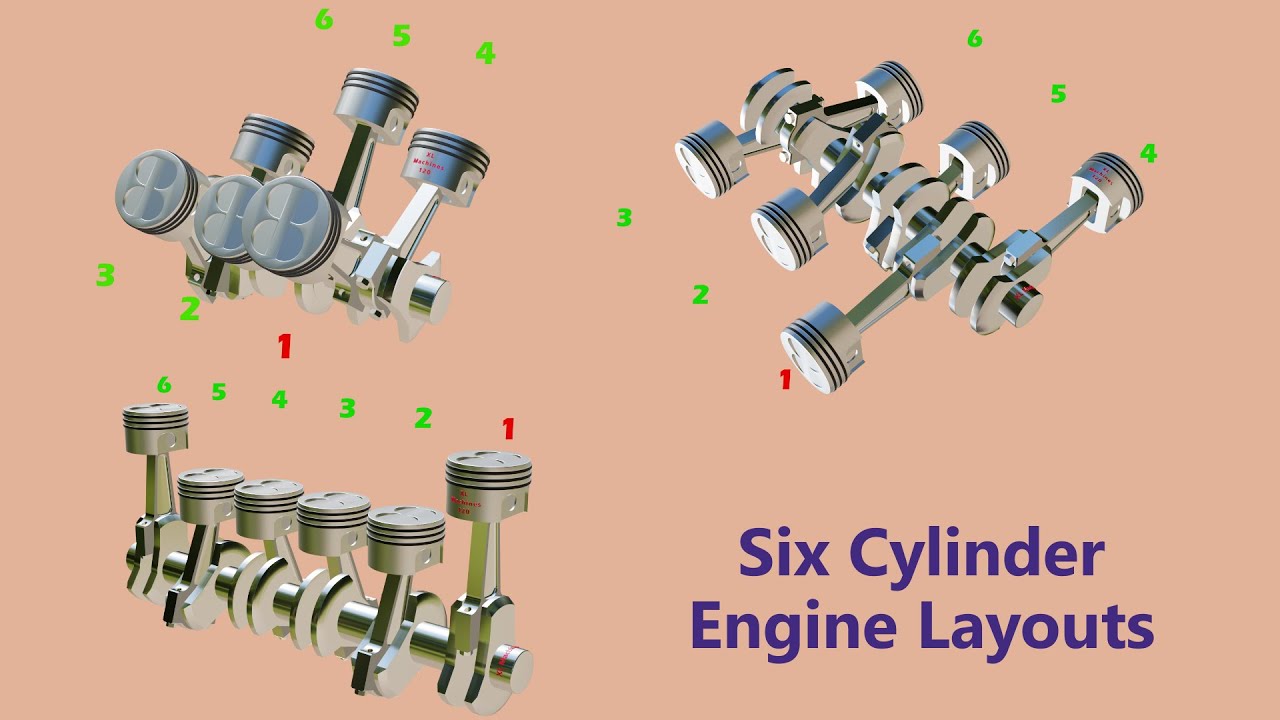

A 6-cylinder engine, at its core, is an internal combustion engine with six cylinders where the combustion process happens. These cylinders are arranged in various configurations, the most common being:

- Inline-6 (I6): All cylinders are arranged in a single straight line. Known for its smooth operation and inherent balance.

- V6: Two banks of three cylinders arranged at an angle (typically 60 or 90 degrees) forming a "V" shape. More compact than an inline-6.

- Flat-6 (Boxer-6): Two banks of three cylinders arranged horizontally, opposing each other. Offers a low center of gravity and excellent balance, common in Porsche vehicles.

Regardless of the configuration, the main components remain largely the same:

- Cylinder Block: The foundation of the engine, housing the cylinders. Usually made of cast iron or aluminum.

- Cylinder Head(s): Sits atop the cylinder block, containing the intake and exhaust valves, spark plugs, and combustion chambers. V6 and Flat-6 engines will have two cylinder heads.

- Pistons: Move up and down within the cylinders, driven by the expanding gases during combustion.

- Connecting Rods (Conrods): Connect the pistons to the crankshaft, converting the reciprocating motion of the pistons into rotational motion.

- Crankshaft: Rotates as the pistons move, providing the power output of the engine.

- Camshaft(s): Controls the opening and closing of the intake and exhaust valves. Can be overhead cam (OHC) or pushrod (OHV) depending on the engine design.

- Valves (Intake & Exhaust): Regulate the flow of air/fuel mixture into the cylinders and exhaust gases out.

- Spark Plugs: Ignite the air/fuel mixture in the combustion chamber (in gasoline engines).

- Intake Manifold: Distributes the air/fuel mixture to the cylinders.

- Exhaust Manifold: Collects exhaust gases from the cylinders.

- Oil Pan: Reservoir for the engine oil.

- Water Pump: Circulates coolant through the engine to regulate temperature.

- Timing Chain/Belt: Connects the crankshaft and camshaft(s), ensuring proper valve timing.

- Fuel Injectors: Spray fuel into the intake manifold or directly into the cylinder (depending on the fuel injection system).

Key Specs to Consider:

- Displacement: The total volume displaced by all the pistons during one stroke (measured in liters or cubic inches). A larger displacement generally means more power.

- Bore and Stroke: Bore is the diameter of the cylinder; stroke is the distance the piston travels. These dimensions influence engine characteristics (torque vs. horsepower).

- Compression Ratio: The ratio of the cylinder volume when the piston is at the bottom of its stroke to the volume when it's at the top. Higher compression ratios generally lead to more power but require higher octane fuel.

- Firing Order: The sequence in which the cylinders fire. Impacts engine balance and smoothness. A common firing order for an inline-6 is 1-5-3-6-2-4.

How a 6-Cylinder Engine Works: The 4-Stroke Cycle

Most 6-cylinder engines operate on the 4-stroke cycle, also known as the Otto cycle (for gasoline engines):

- Intake: The intake valve opens, and the piston moves down, drawing a mixture of air and fuel into the cylinder.

- Compression: The intake valve closes, and the piston moves up, compressing the air/fuel mixture.

- Combustion (Power): The spark plug ignites the compressed mixture, creating a rapid expansion of gases that forces the piston down. This is the power stroke that turns the crankshaft.

- Exhaust: The exhaust valve opens, and the piston moves up, pushing the exhaust gases out of the cylinder.

This cycle repeats continuously in each cylinder, with the firing order carefully timed to deliver smooth and consistent power output. The crankshaft converts the reciprocating motion of the pistons into rotary motion, which is then transmitted to the transmission and ultimately to the wheels.

Real-World Use: Basic Troubleshooting Tips

Here are a few common issues you might encounter with a 6-cylinder engine, along with potential causes:

- Misfire: Rough idling, reduced power, and a check engine light. Possible causes: faulty spark plugs, ignition coils, fuel injectors, vacuum leaks, or low compression.

- Rough Idle: Unstable engine speed at idle. Could be caused by vacuum leaks, a dirty throttle body, a faulty idle air control valve, or issues with the fuel system.

- Loss of Power: Reduced acceleration and overall performance. Possible causes: clogged air filter, failing fuel pump, restricted exhaust, or worn-out components.

- Oil Leaks: Visible oil leaks around the engine. Common areas include valve cover gaskets, oil pan gasket, and front/rear main seals.

- Coolant Leaks: Loss of coolant, overheating. Check for leaks around the radiator, hoses, water pump, and head gasket.

Diagnostic Tools: A basic OBD-II scanner is essential for reading trouble codes. A multimeter can help diagnose electrical issues. A compression tester can assess the health of the cylinders.

Safety First! Risky Components and Precautions

Working on an engine involves inherent risks. Always prioritize safety:

- Electrical System: Disconnect the battery before working on any electrical components to prevent shorts and shocks. Be especially cautious around the ignition system, which carries high voltage.

- Fuel System: Fuel is highly flammable. Work in a well-ventilated area, avoid sparks or open flames, and properly dispose of any fuel-soaked rags.

- Hot Surfaces: Allow the engine to cool down completely before working on it. Exhaust manifolds and other components can remain extremely hot for a long time.

- Moving Parts: Keep your hands and tools away from moving parts, especially when the engine is running.

- Lifting Heavy Components: Use appropriate lifting equipment (engine hoist, jacks) and follow safety guidelines to prevent injuries.

- Sharp Edges: Many engine components have sharp edges. Wear gloves to protect your hands.

Special Warning: The timing chain or timing belt is critical for proper engine function. If it breaks, it can cause catastrophic engine damage. Always replace it according to the manufacturer's recommended interval.

Remember, if you're unsure about any procedure, consult a qualified mechanic. It's better to be safe than sorry.

Now that you have a solid understanding of the 6-cylinder engine, you're well-equipped to tackle repairs, modifications, and maintenance tasks with confidence. We have a detailed diagram of a typical 6-cylinder engine that visually reinforces everything we've covered. This file is available for download to help you with your next project.