What Is A Beam Wiper Blade

Alright, let's dive into beam wiper blades. If you're looking to upgrade your wipers, understand how they work, or troubleshoot some common issues, this explanation will give you a solid technical understanding. We're going to get into the nitty-gritty of their design and operation, just like I would if you were standing here in the garage with me. We even have a diagram you can download at the end to really put it all together. Let's get started.

Key Specs and Main Parts of a Beam Wiper Blade

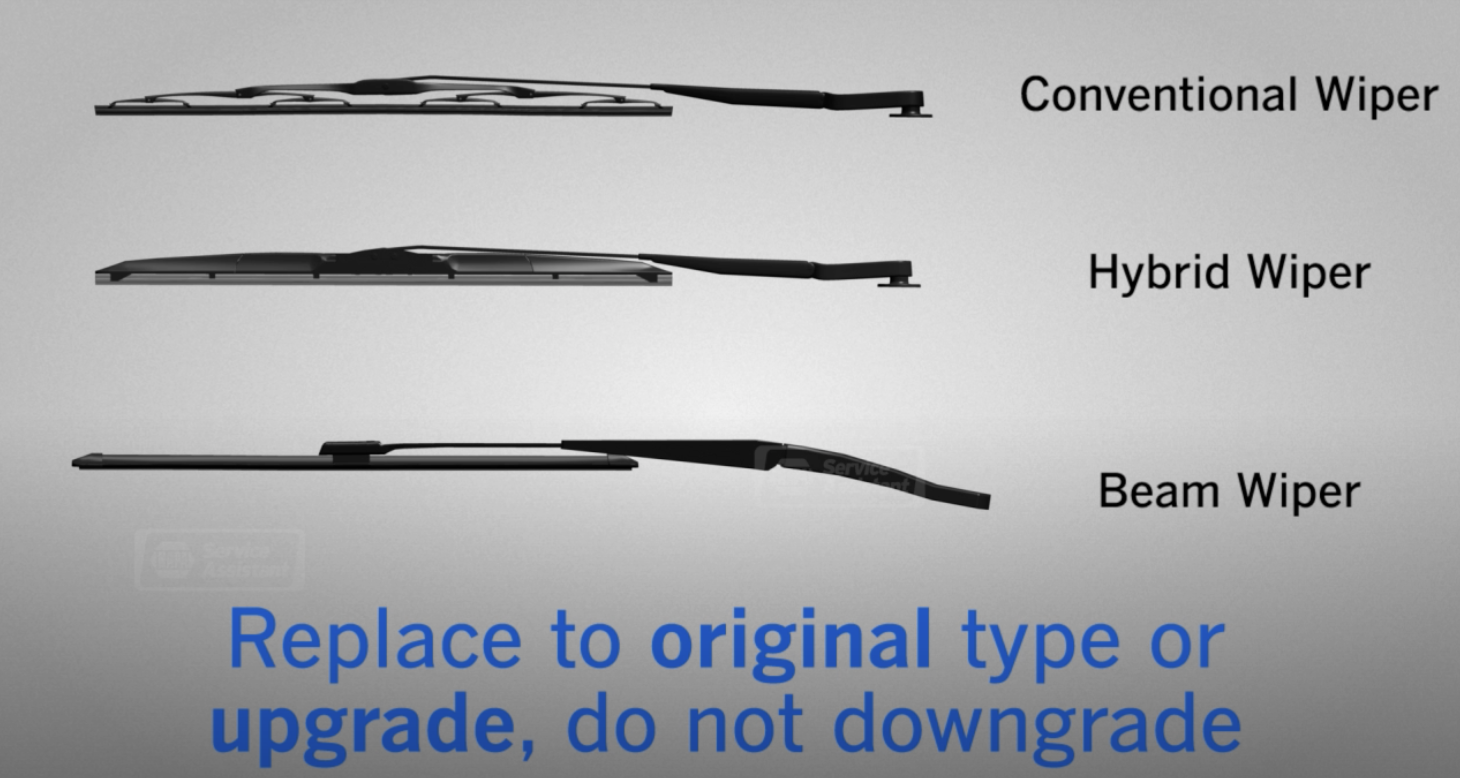

Unlike traditional wiper blades that use a hinged metal frame, beam blades, also known as flat blades, rely on a single, curved piece of spring steel embedded within a rubber or silicone casing. This design distributes pressure more evenly across the windshield. Here are the key parts to know:

- Blade Element (Rubber/Silicone): This is the part that actually contacts the windshield and wipes away water, snow, and debris. It's typically made of natural rubber, synthetic rubber, or silicone. Silicone blades are often more expensive but offer superior durability and performance, especially in extreme temperatures.

- Beam Spring Steel: This is the backbone of the beam blade. It's a specially curved piece of spring steel that provides the necessary tension to conform the blade to the windshield's curvature. The curvature is crucial for even pressure distribution. Think of it like a carefully calibrated spring; its shape is not arbitrary.

- Spoiler (Aerodynamic Deflector): Many beam blades incorporate a spoiler, an aerodynamic feature molded into the blade housing. This spoiler helps to increase downforce on the blade at higher speeds, preventing lift and ensuring consistent contact with the windshield. It's especially important on vehicles with steeply raked windshields.

- Housing/Casing: The rubber or plastic housing encases the spring steel and provides structural support for the blade element. It also protects the internal components from the elements.

- Adapter/Connector: This is the interface between the wiper blade and the wiper arm. Beam blades come with a variety of adapters to fit different wiper arm styles (e.g., hook, bayonet, pin). It's critical to choose the correct adapter for your vehicle.

How a Beam Wiper Blade Works

The magic of a beam wiper blade lies in its ability to apply consistent pressure along its entire length. Here’s the breakdown:

- Even Pressure Distribution: The curved spring steel embedded within the blade ensures that the wiping edge conforms precisely to the windshield's curvature. This eliminates the streaking and uneven wiping that can occur with traditional frame-style blades, especially on curved windshields. Traditional blades rely on multiple pressure points created by the frame, which can lead to gaps and inconsistencies.

- Aerodynamic Performance: As mentioned, the spoiler (if present) plays a crucial role at higher speeds. Air flowing over the spoiler creates downforce, effectively pressing the blade against the windshield. This prevents the blade from lifting off the glass, which is a common problem with traditional blades at highway speeds.

- Wiping Action: As the wiper arm moves the blade across the windshield, the blade element removes water, snow, and debris. The blade element's shape and material determine its wiping effectiveness. A sharp, clean edge is essential for streak-free wiping.

- Flexibility and Durability: The beam design allows the blade to flex and adapt to minor imperfections in the windshield surface. This flexibility contributes to longer blade life and improved wiping performance over time. The lack of exposed metal joints, compared to traditional blades, also makes them less susceptible to corrosion and ice buildup.

Real-World Use & Basic Troubleshooting

So, you've got beam blades installed and they're not performing as expected? Here are a few common issues and how to troubleshoot them:

- Streaking: This is often caused by a dirty blade or windshield. Clean both thoroughly with a glass cleaner specifically designed for automotive use. If streaking persists, the blade element may be worn or damaged and require replacement. Also, make sure your windshield washer fluid reservoir is full and using a good quality fluid. In some cases, a film on the windshield caused by car wax or "rain repellent" products can cause streaking. A thorough cleaning with a dedicated windshield cleaner may resolve this.

- Skipping/Chattering: This can be caused by a dry windshield, improper installation, or a worn blade. Ensure the windshield is wet before activating the wipers. Check that the blade is properly seated in the wiper arm and that the adapter is securely attached. If the blade is old or damaged, replace it. Sometimes, adjusting the wiper arm angle slightly can alleviate chattering.

- Smearing: This is typically caused by a greasy or oily film on the windshield. Clean the windshield and blades thoroughly with a degreasing cleaner. Check for leaks from the vehicle's HVAC system, as these can sometimes deposit an oily film on the windshield.

- Noise: Excessive noise can indicate a loose adapter, a damaged blade, or a dry windshield. Inspect the adapter and blade for damage. Ensure the windshield is wet before activating the wipers. Sometimes, the noise can be caused by the wiper arm contacting the edge of the windshield; if this is the case, the wiper arm might be bent and need adjustment or replacement.

Safety Considerations

Working with wiper blades might seem straightforward, but there are a few things to keep in mind for safety:

- Wiper Arm Spring: Be careful when removing or installing wiper blades. The wiper arm spring can snap back against the windshield if not properly controlled, potentially cracking the glass. Always hold the arm securely when removing the blade.

- Sharp Edges: The blade element can have a surprisingly sharp edge. Handle with care to avoid cuts.

- Windshield Washer Fluid: Some windshield washer fluids contain methanol or other harmful chemicals. Avoid contact with skin and eyes. Work in a well-ventilated area when refilling the washer fluid reservoir.

- Electrical System: While the wiper motor itself isn't directly involved in blade replacement, avoid working on the electrical system (e.g., wiper motor wiring) without disconnecting the battery's negative terminal first.

Technical Definitions

To make things perfectly clear, here are some definitions of the terms mentioned above:

- Downforce: The aerodynamic force that presses the wiper blade against the windshield, ensuring proper contact at high speeds.

- Spring Steel: The flexible steel component within the beam blade that distributes pressure evenly across the windshield.

- Adapter: The part of the wiper blade that connects it to the wiper arm; various designs exist to fit different car models.

Beam wiper blades represent a significant improvement over traditional designs. By understanding their components and how they function, you can make informed decisions about maintenance, troubleshooting, and upgrades. You'll find them to be more durable, and less prone to ice buildup, and they usually provide clearer vision.

To further assist in your understanding, we have prepared a detailed diagram of a beam wiper blade, highlighting all the components discussed. You can download it here.