What Is A Bolt Pattern For Rims

So, you're looking to upgrade your rims, maybe do some repairs, or perhaps just wrap your head around a fundamental aspect of wheel fitment. Good on you! Understanding the bolt pattern, also known as the PCD (Pitch Circle Diameter), is absolutely crucial. It’s the DNA of how your wheels attach to your vehicle, and getting it wrong can lead to serious problems – from annoying vibrations to catastrophic wheel failure. In this article, we'll dissect the bolt pattern, explore its key components, and equip you with the knowledge to confidently navigate this essential spec.

Purpose: Why You Need to Know Your Bolt Pattern

Why bother with all this bolt pattern business? Well, the reasons are manifold:

- Wheel Replacement/Upgrades: This is the most common reason. You can’t just slap any wheel onto your car. The bolt pattern must match the pattern on your vehicle's hubs (more on that later).

- Accurate Repairs: If you’re replacing a wheel stud, you need to know the bolt pattern to ensure you get the correct replacement.

- Performance and Safety: Incorrectly fitted wheels, even if they appear to bolt on, can cause stress, vibration, and ultimately, wheel failure. This is a serious safety concern.

- Understanding Wheel Spacers/Adapters: If you’re considering using wheel spacers or adapters to change the offset of your wheels, you need to know your existing bolt pattern and the pattern of the wheels you want to use.

- General Automotive Knowledge: As an experienced DIYer, understanding fundamental concepts like bolt patterns expands your knowledge base and allows you to tackle more complex projects with confidence.

Key Specs and Main Parts: Breaking it Down

Let's dissect the key components of a bolt pattern:

- Number of Bolts/Studs: This is the first part of the bolt pattern. It indicates how many bolts or studs are used to secure the wheel to the hub. Common examples are 4, 5, 6, and 8.

- Pitch Circle Diameter (PCD): This is the diameter of the imaginary circle that passes through the center of each bolt or stud. It's measured in millimeters (mm) or inches (in).

- Bolt Pattern Designation: The bolt pattern is usually expressed as "[Number of Bolts]x[PCD]". For example, 5x114.3mm indicates a 5-bolt pattern with a PCD of 114.3mm.

- Hub Centricity: While not strictly part of the bolt pattern *designation*, hub centricity is crucial. A hub-centric wheel is designed to fit snugly onto the center bore of the hub, carrying the weight of the vehicle and reducing stress on the wheel studs. Aftermarket wheels often use hub-centric rings to adapt to different hub sizes. Using lug-centric wheels, which rely solely on the lug nuts/bolts to center the wheel, is less desirable and can lead to vibration issues.

- Offset: The offset is the distance between the wheel's mounting surface (where it contacts the hub) and the wheel's centerline. A positive offset means the mounting surface is closer to the outside of the wheel, while a negative offset means it's closer to the inside. The offset affects how the wheel sits within the wheel well. While not directly related to the bolt pattern, it's an important consideration when choosing new wheels.

- Center Bore: The diameter of the hole in the center of the wheel that fits over the hub.

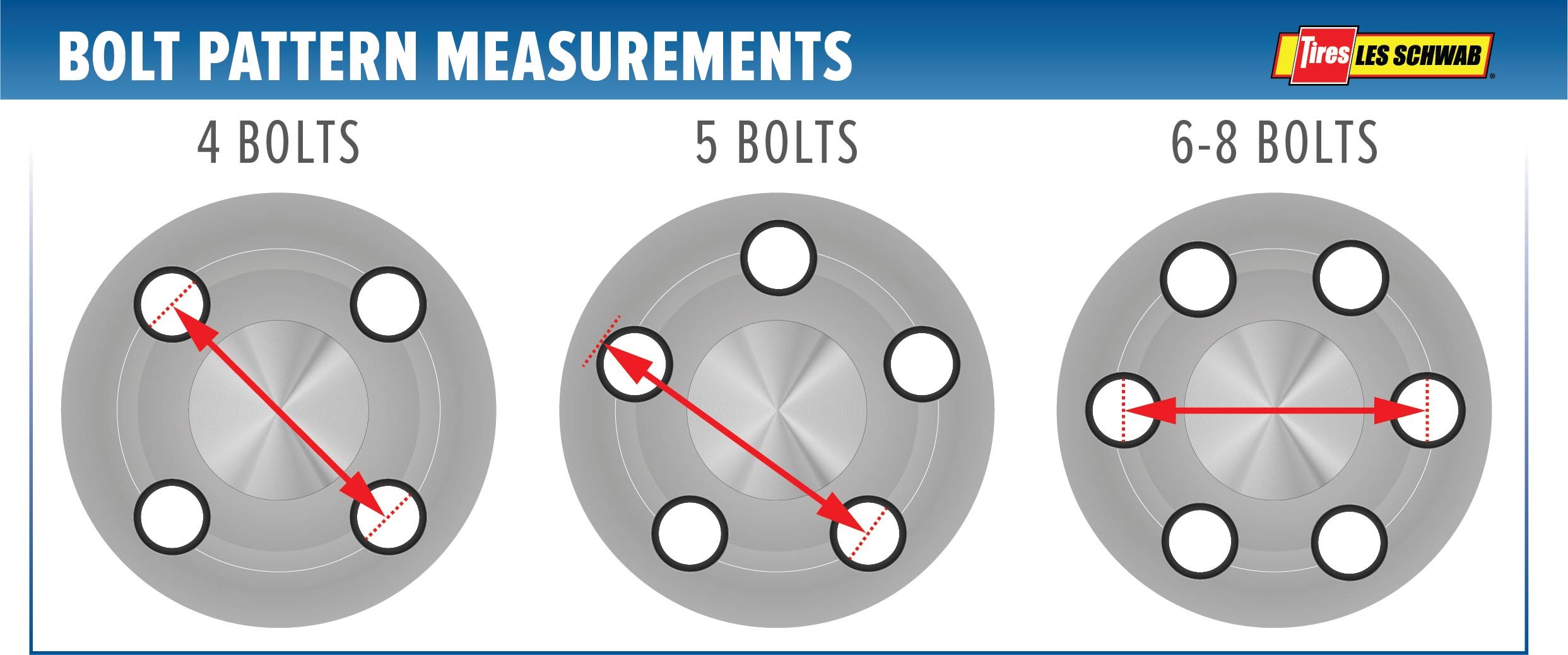

Understanding the PCD Measurement

Measuring the PCD accurately is critical. For 4-bolt patterns, measuring the distance between two opposite bolts is straightforward. For 5-bolt patterns, it's a bit trickier. You can't simply measure across the wheel. You'll need to use a PCD measuring tool, or, lacking that, use trigonometry or online calculators to determine the PCD based on the distance between two adjacent bolts.

How It Works: The Mechanics of Wheel Attachment

The bolt pattern ensures that the clamping force from the lug nuts/bolts is evenly distributed across the wheel hub. When the lug nuts/bolts are tightened correctly, they create a strong friction force between the wheel and the hub, preventing the wheel from slipping. The precise alignment provided by the bolt pattern is vital for maintaining this clamping force and preventing vibration. A mismatched bolt pattern can lead to uneven clamping, causing the lug nuts/bolts to loosen over time, leading to potentially disastrous consequences.

Real-World Use: Basic Troubleshooting Tips

Here are some troubleshooting tips related to bolt patterns:

- Vibrations: If you experience vibrations after installing new wheels, double-check the bolt pattern. Even a slight mismatch can cause significant vibrations. Also, ensure the wheels are properly torqued. Use a torque wrench and follow the manufacturer's recommended torque specifications.

- Difficulty Installing Wheels: If you're having trouble getting the wheel to sit flush against the hub, the bolt pattern may be incorrect. Do not force it!

- Damaged Wheel Studs: Over-tightening lug nuts/bolts or using an impact wrench without proper care can damage wheel studs. Inspect your studs regularly for signs of damage.

- Lug Nut/Bolt Issues: Ensure you are using the correct lug nut/bolt type for your wheels. Different wheels may require different seat types (conical, ball, flat). Using the wrong type can damage the wheel and the hub.

- Hub-Centric Issues: If you are using aftermarket wheels with hub-centric rings, ensure they are properly installed and fit snugly. Loose or missing hub-centric rings can cause vibrations.

Safety: Risky Components and Practices

Working with wheels and tires involves inherent risks. Here are some critical safety considerations:

- Incorrect Bolt Pattern: As emphasized throughout this article, using the wrong bolt pattern is extremely dangerous and can lead to wheel failure.

- Over-Tightening Lug Nuts/Bolts: Over-tightening can damage the wheel studs or warp the wheel hub. Always use a torque wrench and follow the manufacturer's recommended torque specifications.

- Under-Tightening Lug Nuts/Bolts: Under-tightening can cause the lug nuts/bolts to loosen, leading to wheel separation. Check lug nut/bolt torque regularly, especially after installing new wheels.

- Damaged Wheel Studs: Replace damaged wheel studs immediately. Do not drive with damaged studs.

- Using Incorrect Lug Nut/Bolt Type: Using the wrong lug nut/bolt type can damage the wheel and the hub, leading to wheel failure.

- Improper Lifting: Always use a jack stand when working under a vehicle. Never rely solely on a jack.

- Tire Pressure: Maintain proper tire pressure as recommended by the tire manufacturer. Under-inflated or over-inflated tires can affect handling and safety.

Remember, working on your vehicle requires caution and attention to detail. If you're unsure about any aspect of wheel fitment or safety, consult a qualified mechanic.

You now have a solid foundation in understanding bolt patterns. Remember that accuracy is key. Double-check your measurements and consult reliable resources before making any decisions about wheel replacements or upgrades.

For a visual aid and a printable reference, we have a comprehensive bolt pattern diagram available for download. This diagram includes common bolt patterns and measurement techniques. Feel free to download it and keep it handy in your garage. We believe that having the right tools and knowledge will allow you to work safer.