What Is A Cylinder In A Car

Okay, let's dive deep into the heart of your engine – the cylinder. Understanding what a cylinder is, how it works, and its key components is crucial whether you're planning on tackling engine repairs, performance modifications, or just want a deeper understanding of your vehicle. This article is geared toward the DIY enthusiast and provides a technical overview while keeping it practical and accessible.

Why Understanding the Cylinder Matters

Think of the cylinder as the core of your engine’s power plant. It's where the magic – or rather, the combustion – happens that converts fuel into mechanical energy. A solid understanding of the cylinder's function and construction enables you to:

- Diagnose Engine Problems: Misfires, low compression, and excessive oil consumption often stem from cylinder-related issues.

- Perform Repairs: From replacing piston rings to honing cylinder walls, knowing the cylinder’s anatomy is essential for these tasks.

- Plan Modifications: Modifying engine displacement, compression ratio, or valve timing directly impacts cylinder performance.

- Increase Overall Knowledge: A greater comprehension of engine operation gives you a much stronger base for understanding and executing all kinds of maintenance and repair.

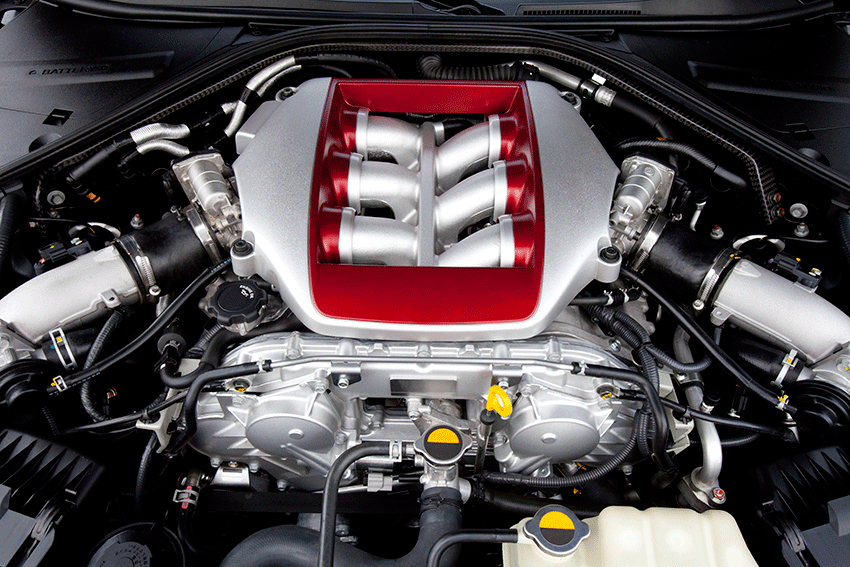

Key Specs and Main Parts of a Cylinder

Let's break down the key specifications and main components of a typical internal combustion engine cylinder:

Key Specs:

- Bore: The diameter of the cylinder. This, combined with the stroke, determines the engine's displacement.

- Stroke: The distance the piston travels from Top Dead Center (TDC) to Bottom Dead Center (BDC).

- Compression Ratio: The ratio of the cylinder volume at BDC to the cylinder volume at TDC. Higher compression ratios generally mean more power, but also require higher octane fuel and can increase stress on engine components.

- Displacement: The total volume swept by the piston as it moves from BDC to TDC, measured in cubic centimeters (cc) or liters (L). A larger displacement usually means more power.

Main Parts:

- Cylinder Block: The main housing of the engine, containing the cylinders. It’s typically made of cast iron or aluminum.

- Cylinder Head: Sits atop the cylinder block and houses the valves, spark plugs (or injectors in a diesel engine), and combustion chamber.

- Piston: A cylindrical component that moves up and down inside the cylinder. It's connected to the connecting rod.

- Piston Rings: Located in grooves on the piston, they seal the combustion chamber, prevent oil from entering the combustion chamber, and transfer heat from the piston to the cylinder wall.

- Connecting Rod: Connects the piston to the crankshaft, converting the piston's reciprocating motion into the crankshaft's rotary motion.

- Crankshaft: A rotating shaft that converts the linear motion of the pistons into rotary motion, which is then transmitted to the transmission.

- Valves (Intake & Exhaust): Control the flow of air/fuel mixture into the cylinder (intake valve) and the exhaust gases out of the cylinder (exhaust valve).

- Spark Plug (Gasoline Engines): Provides the spark that ignites the air/fuel mixture. Diesel engines use glow plugs for starting in cold weather.

- Fuel Injector (Direct Injection Engines): Sprays fuel directly into the cylinder. Some older engines utilize port fuel injection into the intake port.

How It Works: The Four-Stroke Cycle

Most modern car engines operate on a four-stroke cycle. Let's break down each stroke:

- Intake Stroke: The piston moves down, creating a vacuum. The intake valve opens, allowing the air/fuel mixture to be drawn into the cylinder.

- Compression Stroke: The intake valve closes, and the piston moves up, compressing the air/fuel mixture. This increases the mixture's temperature and pressure, making it easier to ignite.

- Combustion (Power) Stroke: At the peak of compression, the spark plug ignites the air/fuel mixture. The resulting explosion forces the piston down, generating power.

- Exhaust Stroke: The exhaust valve opens, and the piston moves up, pushing the burnt exhaust gases out of the cylinder and into the exhaust manifold.

Real-World Use: Basic Troubleshooting Tips

Here are some basic troubleshooting tips related to cylinders:

- Misfires: Can be caused by a faulty spark plug, ignition coil, fuel injector, vacuum leak, or low compression in the cylinder. A compression test is a great tool to diagnose this.

- Low Compression: Indicates a leak in the cylinder, potentially due to worn piston rings, damaged valves, or a blown head gasket.

- Excessive Oil Consumption: Can be caused by worn piston rings or damaged cylinder walls.

- White Smoke from Exhaust: Usually indicates coolant entering the combustion chamber, often due to a blown head gasket or cracked cylinder head.

- Blue Smoke from Exhaust: Indicates oil burning in the combustion chamber, often due to worn piston rings or valve stem seals.

- Black Smoke from Exhaust: Indicates excessive fuel, often due to a faulty fuel injector, or a problem with the engine's air/fuel mixture control.

These are general guidelines. A proper diagnosis often requires specialized tools and knowledge. When in doubt, consult a professional mechanic.

Safety: Risky Components

Working on the engine, especially around the cylinder, involves inherent risks:

- High Temperatures: Engine components, especially the cylinder head and exhaust manifold, get extremely hot. Always allow the engine to cool completely before working on it.

- High Pressures: The combustion chamber experiences extremely high pressures. Never attempt to disassemble a cylinder head while it's still pressurized.

- Sharp Edges: Engine components can have sharp edges. Wear gloves to protect your hands.

- Flammable Fluids: Gasoline and other engine fluids are highly flammable. Work in a well-ventilated area and avoid sparks or open flames.

- Moving Parts: Never start the engine with the cylinder head removed or with any components exposed.

Always disconnect the battery's negative terminal before working on any electrical components. If you're unsure about any procedure, consult a qualified mechanic.

Let's Wrap Up

Understanding the cylinder and its role in the internal combustion engine is fundamental for any serious DIY mechanic. By grasping the key specs, components, working principles, and troubleshooting techniques, you're better equipped to diagnose issues, perform repairs, and even explore engine modifications. Remember to prioritize safety and consult a professional when facing complex or unfamiliar tasks.

For more in-depth information, check out online engine diagrams and repair manuals. Many manufacturers provide detailed illustrations and specifications that can further enhance your understanding. With knowledge and proper care you'll be well equipped to service and maintain your vehicles engine for years to come!