What Is A Drive Belt In A Car

Alright, let's talk drive belts. You'll hear them called serpentine belts, accessory belts, and sometimes even V-belts (though those are becoming less common). Understanding this system is crucial for diagnosing a whole host of car problems, and even preventative maintenance. This article aims to give you a solid understanding of the system, empowering you to troubleshoot issues and maybe even tackle a replacement yourself. Think of it as your deep dive into the world of automotive beltology!

Purpose: Powering Your Car's Accessories

The drive belt's primary function is to transfer rotational power from the engine's crankshaft to various accessories that need to spin. Think of it as a power delivery system, but instead of electricity, it's mechanical energy doing the work. This is why understanding this system matters – a failing belt can cripple vital components, leaving you stranded. Knowing the system well allows for preventative repairs, saving costly trips to the mechanic.

Key Specs and Main Parts

Let's break down the components and the measurements that matter:

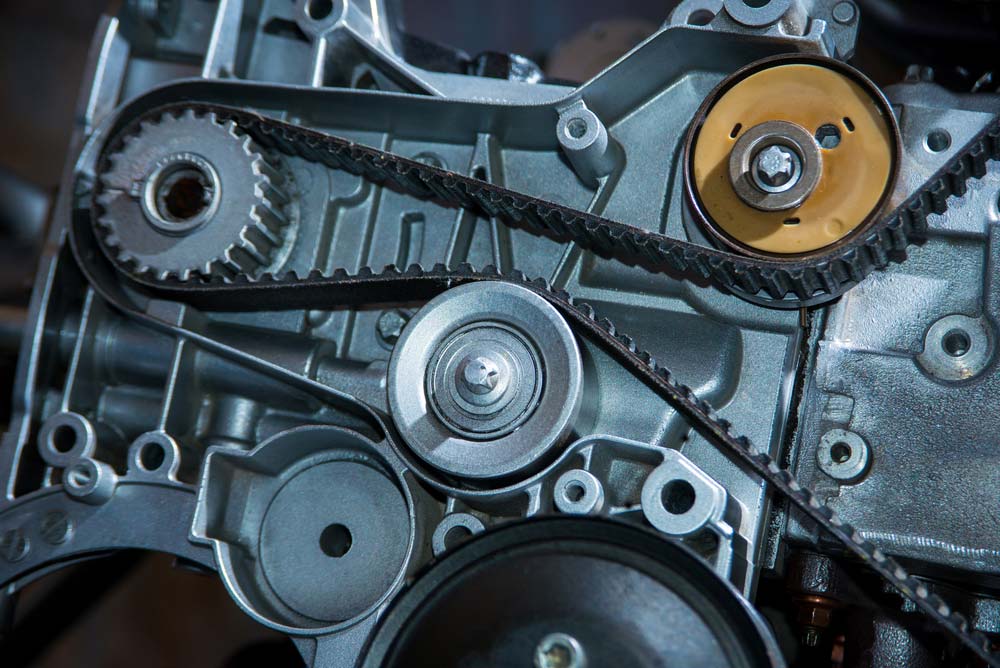

Components: The Players in the System

- Crankshaft Pulley: This is the drive pulley. It's directly connected to the crankshaft and is the starting point of the power transfer. Its size affects the speed at which the other accessories rotate.

- Alternator Pulley: The alternator generates electricity to power the car's electrical system and charge the battery. The drive belt spins the alternator.

- Power Steering Pump Pulley: Spins the power steering pump, providing hydraulic assistance to make steering easier.

- Air Conditioning Compressor Pulley: Rotates the A/C compressor, which circulates refrigerant to cool the car's cabin.

- Water Pump Pulley: (Sometimes driven by the drive belt) The water pump circulates coolant through the engine to prevent overheating.

- Tensioner Pulley: A spring-loaded pulley that maintains the correct tension on the drive belt. Crucially important for preventing slippage and ensuring proper accessory operation.

- Idler Pulley: A smooth pulley used to guide the belt around other components and prevent rubbing or interference.

Key Specs: What the Numbers Mean

- Belt Length: Measured in millimeters or inches. This is the most critical dimension when replacing a belt. Using the wrong length will result in incorrect tension.

- Belt Width: Also measured in millimeters or inches. Ensures the belt fits properly in the grooves of the pulleys.

- Number of Ribs (Serpentine Belts): The number of 'v' shaped ribs that run along the length of the belt. This needs to match the pulleys.

- Material: Typically made from EPDM (Ethylene Propylene Diene Monomer) rubber, which offers good resistance to heat, oil, and abrasion. Some high-performance belts use reinforced materials like aramid fibers (Kevlar) for increased strength and durability.

How It Works: The Power Flow

The magic of the drive belt system lies in its simplicity. The crankshaft pulley, driven by the engine's combustion process, spins. The drive belt, wrapped around this pulley and all the accessory pulleys, transfers this rotational force. As the crankshaft pulley spins, it forces the belt to move, which in turn rotates the accessory pulleys. The tensioner pulley ensures that the belt remains tight against all the pulleys, preventing slippage and maximizing power transfer. Without the correct tension, the belt will slip and accessories will operate sub-optimally or not at all. This can be heard as a distinct squealing noise.

Real-World Use: Troubleshooting Like a Pro

Here are some common problems and how to troubleshoot them:

- Squealing Noise: This is the most common symptom of a problem. It usually indicates a loose or worn belt. Check the belt tensioner. If the tensioner seems okay, inspect the belt for cracks, glazing (a shiny, hardened surface), or missing ribs.

- Cracked or Frayed Belt: A visually inspected belt will show degradation. Replace the belt immediately.

- Accessory Failure: If an accessory, like the alternator or power steering pump, suddenly stops working, the drive belt is a prime suspect. Check for a broken belt or excessive slippage. If the belt looks and feels okay, the issue might be with the accessory itself.

- Battery Light On: This usually indicates a charging problem. The drive belt may be slipping on the alternator pulley, preventing it from generating enough electricity.

- Overheating: If the water pump is driven by the drive belt, a slipping or broken belt can cause the engine to overheat.

Basic Troubleshooting Steps:

- Visual Inspection: Check the belt for cracks, fraying, missing ribs, and glazing.

- Tension Check: Ensure the belt has proper tension. You can usually check this by pressing on the belt between two pulleys. It shouldn't deflect more than about ½ inch.

- Pulley Alignment: Make sure all the pulleys are aligned correctly. Misalignment can cause excessive belt wear and noise. A straight edge can be useful for checking pulley alignment.

- Belt Dressing (Temporary Fix): While not a long-term solution, belt dressing can temporarily reduce slippage and noise. However, it's just a band-aid fix and should not replace addressing the underlying issue.

Safety: Highlighting Risky Components

Warning: The drive belt area contains moving parts that can cause serious injury. NEVER work on the drive belt system while the engine is running. Always disconnect the negative battery cable before working on any part of the electrical system. When working around the engine, be aware of hot surfaces like the exhaust manifold. Pay specific attention to the cooling fan, particularly on older vehicles. These fans can engage even when the engine is off due to a temperature sensor. Always disconnect the fan or be extremely careful around it. Before starting the engine after replacing the drive belt, double-check that all tools and debris have been removed from the engine bay.

Also, the tensioner pulley has a strong spring. When releasing the tension, use the correct tool and be prepared for the sudden release of force. Always wear safety glasses when working on the drive belt system to protect your eyes from debris.

Additional Tips for Success

- Take a Picture: Before removing the old belt, take a picture or draw a diagram of how it's routed around the pulleys. This will make reinstallation much easier.

- Use the Right Tools: Invest in a good set of wrenches, sockets, and a belt tensioner tool.

- Quality Matters: When replacing the belt, choose a high-quality replacement from a reputable manufacturer.

- Consider Replacing the Tensioner: If the tensioner is old or worn, consider replacing it at the same time as the belt. This can prevent future problems and save you time in the long run.

Drive belts are an integral piece of keeping your car moving. Now with your newfound knowledge, you should be well on your way to identifying, and potentially resolving, most belt issues.