What Is A Drive Belt On A Car

So, you're ready to dive deeper into the inner workings of your car's engine? Excellent! Today, we're tackling a crucial component that often gets overlooked until it squeals its protest – the drive belt. This unsung hero is responsible for powering a whole host of auxiliary systems, making it absolutely vital to your vehicle's operation. We're going to break down everything you need to know, from its purpose and key specs to troubleshooting and safety considerations. Consider this your comprehensive guide to understanding, diagnosing, and potentially replacing your car's drive belt. We’ll be referencing a detailed diagram throughout this explanation – and we’ve got that file ready for you to download at the end.

Purpose: Keeping Things Moving

Why does understanding the drive belt matter? Simple: because a failed drive belt can leave you stranded. It's responsible for transferring rotational power from the engine's crankshaft to essential accessories. Think of it as a mechanical lifeline. Understanding its operation allows you to perform preventative maintenance, diagnose problems early, and even tackle the replacement yourself, saving you time and money. Whether you're planning on tuning your engine, diagnosing that annoying squeal, or simply want to better understand your car, knowing the ins and outs of the drive belt is essential. It's also key to identifying potential problems *before* they leave you stuck on the side of the road.

Key Specs and Main Parts

The drive belt system isn't just a single belt; it's a carefully orchestrated arrangement of components. Here's a breakdown of the key players:

- Crankshaft Pulley: This is where the engine's rotational power originates. It's connected directly to the crankshaft and drives the entire system.

- Drive Belt (Serpentine or V-Belt): The star of the show! This belt, usually made of reinforced rubber, transmits the power from the crankshaft pulley to the other pulleys. There are two main types:

- Serpentine Belt: A single, long belt that snakes around multiple pulleys, powering several accessories. It’s characterized by its multiple grooves, allowing it to grip the pulleys more effectively.

- V-Belt: Older systems may use V-belts, which are trapezoidal in cross-section and typically dedicated to powering a single accessory.

- Accessory Pulleys: These are connected to the various accessories the drive belt powers, such as:

- Alternator: Charges the car's battery and powers the electrical system.

- Power Steering Pump: Provides hydraulic assistance for steering.

- Air Conditioning Compressor: Compresses refrigerant for the air conditioning system.

- Water Pump: Circulates coolant to regulate engine temperature.

- Tensioner Pulley: This spring-loaded pulley maintains the correct tension on the drive belt, preventing slippage and premature wear. An improperly functioning tensioner is a common cause of drive belt problems.

- Idler Pulley: A smooth pulley that simply guides the belt's path, often used to change the belt's angle or prevent it from contacting other components.

When looking at the specs of a drive belt, you'll typically see a part number (which dictates the length and number of ribs for serpentine belts, or the length and top width for V-belts). It's crucial to use the correct part number for your specific vehicle. Using the wrong belt can lead to improper tension, slippage, and damage to the belt and accessories.

How It Works

The operating principle is simple, yet effective. The engine's crankshaft rotates, turning the crankshaft pulley. The drive belt, which is in constant contact with the crankshaft pulley and the accessory pulleys, transfers this rotational energy to those accessories. As the crankshaft pulley spins, it pulls on the belt, causing the accessory pulleys to rotate, thus powering the alternator, power steering pump, A/C compressor, and water pump.

The tensioner pulley plays a critical role in maintaining the correct amount of tension on the belt. Too little tension leads to slippage, which reduces the efficiency of the accessories and can cause the belt to overheat and wear out quickly. Too much tension can put excessive strain on the accessory bearings, shortening their lifespan. The tensioner automatically adjusts to maintain the optimal tension, compensating for belt stretch and wear.

Real-World Use: Basic Troubleshooting Tips

Here are a few common symptoms and potential causes related to drive belt problems:

- Squealing Noise: This is often the first sign of a problem. It's usually caused by belt slippage, which can be due to:

- Worn or Glazed Belt: The belt's surface becomes hard and shiny, reducing its grip.

- Loose Tensioner: The tensioner isn't applying enough pressure to the belt.

- Contamination: Oil, coolant, or other fluids on the belt can cause it to slip.

- Misaligned Pulleys: A pulley that isn't properly aligned can cause the belt to rub and squeal.

- Cracked or Frayed Belt: This indicates that the belt is nearing the end of its life. Replace it immediately to avoid a breakdown.

- Accessory Failure: If an accessory, such as the alternator or power steering pump, isn't functioning properly, it could be due to a slipping drive belt.

To troubleshoot, start by visually inspecting the belt for cracks, frays, and glazing. Check the tensioner pulley to ensure it's moving freely and applying adequate pressure. You can also use a belt dressing spray (sparingly!) to temporarily reduce slippage and confirm the source of the noise. However, belt dressing is a temporary fix and a worn belt should still be replaced.

You can also use a multimeter to check the output of your alternator. A failing alternator, drawing more power than it should, can place extra strain on the drive belt, causing it to slip and squeal.

Safety: Highlight Risky Components

Working on the drive belt system can be dangerous, especially if the engine is running. Never attempt to adjust the tensioner or work on the belt while the engine is running. The rapidly rotating pulleys can cause serious injury. Ensure the engine is completely off and the key is removed from the ignition. Disconnect the negative battery terminal for added safety.

The cooling fan, located near the drive belt, is another potential hazard. Be extremely cautious when working near the fan, as it can start unexpectedly if the engine is bumped or the ignition is turned on. Make sure the fan is clear of any tools or clothing.

When replacing the drive belt, always use the correct tools, including a belt tensioner tool. This tool allows you to safely release the tension on the belt and remove it without damaging the tensioner or other components.

Finally, remember that the engine and exhaust components can be very hot. Allow the engine to cool down completely before working on the drive belt system to avoid burns.

Symbols and Our Diagram (Which You Can Download!)

A good drive belt diagram will show the routing of the belt around all the pulleys. The diagram often uses:

- Solid Lines: These represent the drive belt itself. The thickness of the line may indicate the belt's width.

- Circles: These represent the pulleys. The diameter of the circle is often proportional to the pulley's actual size.

- Arrows: These indicate the direction of rotation of the pulleys. Pay close attention to these arrows, as they are crucial for understanding how the belt is routed.

- Labels: Each pulley should be labeled with its corresponding component (e.g., "Crankshaft Pulley," "Alternator," "Power Steering Pump").

- Colors (Optional): Some diagrams use color to differentiate between different types of pulleys or belts.

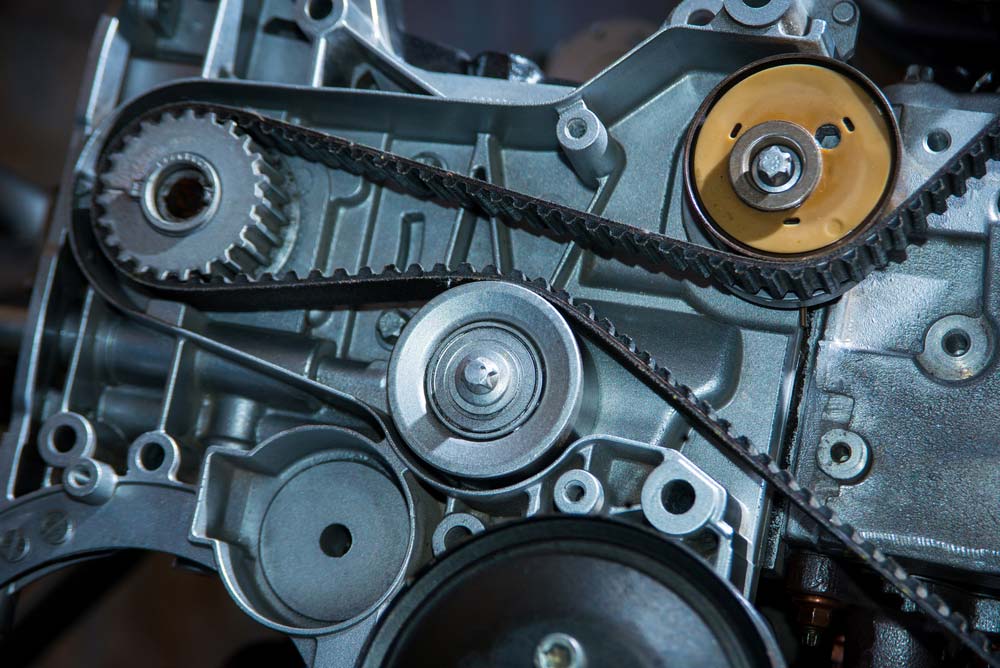

Now, to help you further understand the drive belt system, we have compiled a comprehensive diagram that clearly illustrates all the components and their arrangement. This diagram includes detailed labels, arrows indicating the direction of rotation, and visual representations of the belt routing. With this diagram, you'll be able to easily identify the various pulleys, understand how the belt is routed, and confidently troubleshoot any issues you may encounter.

Ready to download the diagram? [Link to Diagram Here] It’s formatted for easy printing and reference while you’re working on your car. Good luck and happy wrenching!