What Is A Front Wheel Drive

So, you're looking to dive deeper into the world of front-wheel drive (FWD) vehicles? Excellent choice! Understanding the mechanics behind your car – or a project car you're working on – is crucial for informed repairs, modifications, and even just knowing when something isn't quite right. This isn't just about bragging rights; it's about safety and saving money in the long run. This article breaks down the ins and outs of FWD, from the key components to troubleshooting common issues.

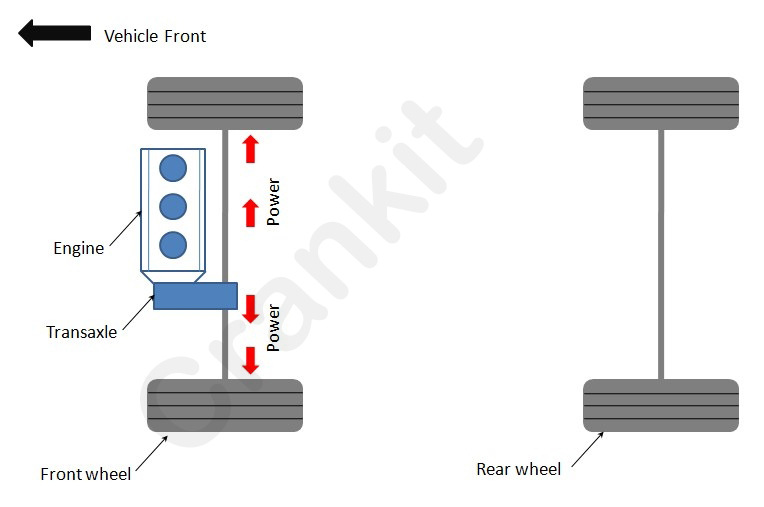

Key Specs and Main Parts of a Front-Wheel Drive System

At its core, FWD means that the engine's power is primarily delivered to the front wheels. This is achieved through a carefully engineered system consisting of several key components. Understanding these components is the first step in diagnosing any problems and executing repairs.

Engine

The engine, whether it's an inline-four, V6, or even a smaller configuration, is the heart of the system. It generates the power that ultimately drives the wheels. While the engine itself isn't exclusive to FWD, its placement (typically transverse, meaning sideways) is common in FWD vehicles to optimize space efficiency.

Transmission (Transaxle)

The transmission, often called a transaxle in FWD configurations, is a complex gearbox that manages the engine's output. It uses different gear ratios to multiply torque at lower speeds for acceleration and provide higher gears for efficient cruising. In a FWD vehicle, the transmission is usually integrated with the differential, forming a single unit – hence the term "transaxle." This integration saves space and weight.

Differential

The differential is a crucial component that allows the front wheels to turn at different speeds. This is essential when cornering because the wheel on the outside of the turn travels a longer distance than the wheel on the inside. Without a differential, the wheels would bind and scrub, making turning difficult and potentially damaging the drivetrain. Open differentials are common, but limited-slip differentials (LSDs) can improve traction, especially in performance applications.

Drive Shafts (Half Shafts)

Drive shafts, also known as half shafts, connect the differential to the front wheels. These shafts are responsible for transmitting the torque from the differential to the wheels, causing them to rotate. They feature constant-velocity (CV) joints at each end to allow for independent suspension movement and steering articulation without binding or vibration.

Constant-Velocity (CV) Joints

CV joints are flexible joints that allow the drive shafts to transmit power smoothly even when the wheels are turning or the suspension is moving up and down. They are typically protected by rubber boots filled with grease. These boots are crucial; a torn boot allows dirt and moisture to contaminate the joint, leading to premature wear and eventual failure.

Steering System

While not exclusively part of the drivetrain, the steering system is intimately linked to the front wheels in a FWD vehicle. The steering rack and tie rods are responsible for translating the driver's steering input into wheel movement. The interaction between the drivetrain and steering is essential for controlling the vehicle.

How Front-Wheel Drive Works

The operation of a FWD system can be summarized as a sequence of power transfer. First, the engine generates power through combustion. That power is then channeled through the transmission, where the driver selects the appropriate gear ratio. The transmission then transfers the power to the differential, which splits the torque and allows the front wheels to rotate at different speeds. Finally, the drive shafts transmit the torque from the differential to the front wheels, propelling the vehicle forward.

The integrated nature of the transaxle is a defining characteristic. By combining the transmission and differential into a single unit, manufacturers can save space and reduce weight, which contributes to better fuel economy and handling in many FWD vehicles. This design also makes the vehicle easier to package, allowing for more interior space.

Real-World Use – Basic Troubleshooting Tips

Knowing the symptoms of common FWD problems can save you time and money. Here are a few basic troubleshooting tips:

- Clicking or Popping Sounds While Turning: This is a classic sign of worn or damaged CV joints. The clicking is caused by the joint binding and releasing as it rotates. Inspect the CV boot for tears and grease leaks. If the boot is intact, the joint itself may be worn internally.

- Vibrations at High Speeds: Vibrations can be caused by a variety of factors, including unbalanced tires, worn suspension components, or a bent drive shaft. If the vibration is only present at certain speeds, it's more likely to be related to tire balance. However, a bent drive shaft can also cause vibrations that increase with speed.

- Wheel Hop During Acceleration: Wheel hop occurs when the tires lose and regain traction rapidly, causing the vehicle to shake. This is often caused by worn engine mounts, which allow the engine to move excessively under acceleration. Upgrading to stiffer engine mounts can help reduce wheel hop, but may also increase NVH (noise, vibration, and harshness).

- Difficulty Shifting: Difficulty shifting gears can indicate a problem with the transmission. This could be due to low transmission fluid, worn synchronizers, or a damaged clutch (in manual transmissions). Check the transmission fluid level and condition. If the fluid is low or dirty, changing it may resolve the issue.

Safety – Highlight Risky Components

Working on a FWD drivetrain involves some inherent risks. Here are a few areas where extra caution is needed:

- CV Joints: When disassembling CV joints, be extremely careful not to damage the internal components. The balls and races must be reassembled in the correct order. Always wear safety glasses to protect your eyes from flying debris.

- Transmission: The transmission contains many intricate parts that can be easily damaged. If you're not comfortable working on transmissions, it's best to leave this job to a professional. Always use the correct tools and follow the manufacturer's instructions carefully.

- Springs: when working on suspension and removing the drive shaft, be very careful with the suspension springs. These are under great tension and can cause serious injury if released uncontrolled. Use proper spring compressors.

- Lifting the Vehicle: Always use jack stands when working underneath a vehicle. Never rely solely on a jack to support the weight of the car. Ensure the jack and jack stands are rated for the weight of the vehicle.

Remember to always disconnect the negative battery cable before working on any electrical components. When dealing with fluids, be aware of their properties and wear appropriate safety gear, such as gloves and eye protection.