What Is A Intake On A Car

Alright, let's dive into the intake system of your car. Understanding how it works is crucial whether you're planning performance upgrades, tackling a repair, or simply want to know your engine better. We’re going to break down the components, the flow, and the potential pitfalls. This isn’t just about knowing the parts; it's about understanding the *why* behind them.

Purpose of Understanding the Intake System

Why should you care about understanding your car's intake? Several reasons. First, diagnosing performance issues. A poorly performing intake system can manifest as reduced fuel economy, sluggish acceleration, and even engine misfires. Second, performing repairs and maintenance. Knowing the layout and function of the components will make replacing air filters, cleaning sensors, and addressing leaks significantly easier. Third, planning performance modifications. Whether you're considering a cold air intake, a throttle body upgrade, or forced induction (turbocharging or supercharging), understanding the stock system is essential for making informed decisions and avoiding compatibility issues. Finally, general automotive knowledge. The more you know about your car, the better equipped you are to maintain it and potentially save money on costly mechanic bills.

Key Specs and Main Parts

The intake system is responsible for delivering clean, cool air to the engine's cylinders. The main parts typically include:

- Air Filter: This is the first line of defense, removing dust, debris, and other contaminants from the incoming air. Regular replacement is critical.

- Intake Piping/Ducting: These tubes and channels guide the air from the air filter to the throttle body or MAF sensor. They’re usually made of plastic or rubber.

- Mass Air Flow (MAF) Sensor (or MAP Sensor): The MAF sensor measures the mass of air entering the engine, while a MAP sensor measures manifold absolute pressure. This information is relayed to the engine control unit (ECU). Some vehicles use both.

- Throttle Body: This regulates the amount of air entering the engine. It’s controlled by the accelerator pedal.

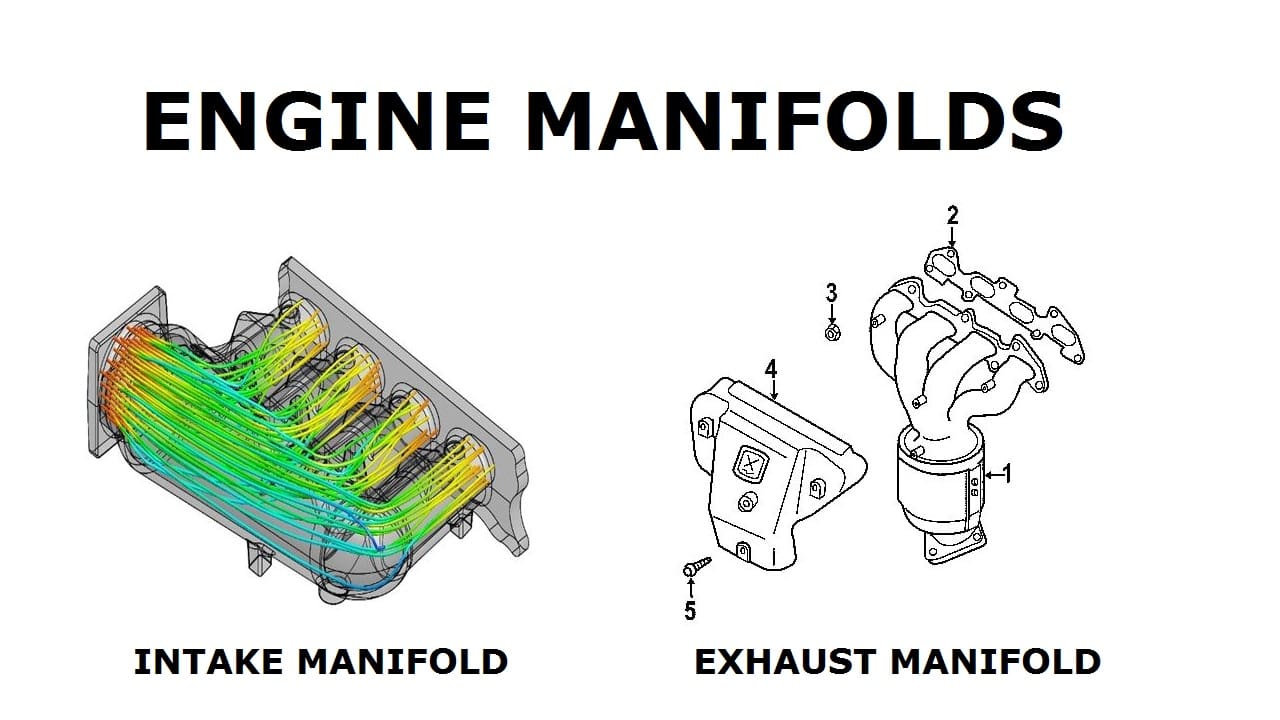

- Intake Manifold: This distributes the air evenly to each cylinder head. It’s often made of aluminum or plastic.

- Intake Valves: Located in the cylinder head, these open and close to allow air into the combustion chamber.

- (Optional) Resonance Chamber: Some systems include a resonance chamber to reduce intake noise or improve airflow.

- (Optional) Turbocharger/Supercharger: For forced induction engines, these components compress the intake air, boosting power.

- Intercooler/Charge Cooler: For turbocharged/supercharged engines, this cools the compressed air before it enters the intake manifold, further increasing density and performance.

Key specs often include the diameter of the intake piping (measured in inches or millimeters), the air filter's flow rate (measured in CFM - cubic feet per minute), and the throttle body's bore size (also in millimeters). Understanding these specs is important when choosing aftermarket components.

How It Works

The intake system operates on a relatively simple principle: drawing air into the engine's cylinders. Here’s a step-by-step breakdown:

- Air Intake: Air enters the system through the air filter, which removes contaminants.

- Airflow Measurement: The MAF or MAP sensor measures the amount of air entering the engine. This information is critical for the ECU to calculate the correct fuel mixture.

- Throttle Control: The throttle body regulates the airflow based on the driver's input (accelerator pedal position). Opening the throttle plate allows more air to enter.

- Distribution: The intake manifold distributes the air evenly to each cylinder. The manifold's design is crucial for ensuring balanced airflow and optimal engine performance.

- Valve Timing: The intake valves open and close at specific times, allowing air to enter the combustion chamber during the intake stroke of the piston.

In a forced induction system, the turbocharger or supercharger compresses the air before it reaches the throttle body, increasing the air density and resulting in more power. The intercooler then cools the compressed air to further enhance density and prevent engine knocking.

Real-World Use – Basic Troubleshooting Tips

Here are some basic troubleshooting tips related to the intake system:

- Check the Air Filter: A clogged air filter restricts airflow, reducing performance and fuel economy. Replace it regularly.

- Inspect Intake Piping: Look for cracks or leaks in the intake piping. Leaks can allow unmetered air to enter the engine, causing it to run lean and potentially damage the catalytic converter.

- Clean the MAF Sensor: A dirty MAF sensor can provide inaccurate readings to the ECU. Use a specialized MAF sensor cleaner to avoid damage.

- Listen for Vacuum Leaks: Use a stethoscope or a spray bottle with soapy water to locate vacuum leaks around the intake manifold and vacuum hoses.

- Check Throttle Body: Inspect the throttle body for excessive carbon buildup. Clean it with throttle body cleaner, following the manufacturer's instructions.

Symptoms of a faulty intake system can include rough idling, stalling, poor acceleration, decreased fuel economy, and a check engine light. Use an OBD-II scanner to retrieve diagnostic trouble codes (DTCs) and narrow down the problem.

Safety – Highlight Risky Components

Working on the intake system involves some safety considerations:

- Hot Surfaces: The intake manifold can become very hot, especially after the engine has been running. Allow the engine to cool down completely before working on it.

- Electrical Components: The MAF sensor and other sensors in the intake system are electrical components. Disconnect the battery before working on these components to avoid electrical shock.

- Flammable Cleaners: Throttle body cleaner and other intake cleaners are flammable. Use them in a well-ventilated area and avoid sparks or open flames.

- Avoid Debris: When working on the intake, be extra careful to prevent debris from entering the system. Cover the intake ports with clean rags when removing components. Debris can damage the engine.

- Tightening Torques: When reinstalling components, use the correct torque specifications to avoid damaging the threads or creating leaks. Consult the vehicle's service manual for torque values.

- Forced Induction Systems: Use extreme caution when working on turbochargers or superchargers as the spinning impellers can cause severe injuries if the system accidentally engages when the engine is running.

Specifically, be cautious when dealing with the throttle body, as it can snap shut unexpectedly. Disconnect the throttle cable or electronic connector before working on it. Also, be aware that some older vehicles may have sharp edges on the intake manifold or throttle body.

Remember to always consult your vehicle's service manual for specific instructions and safety precautions related to your car's intake system. This guide is intended as a general overview.