What Is A King Pin On A Truck

If you're diving into heavy-duty vehicle mechanics, especially concerning steering and front-end alignment, understanding the king pin assembly is crucial. This article will break down the purpose, components, function, and maintenance of this critical part of truck suspension.

Purpose of Understanding the King Pin

The king pin is the linchpin (pun intended!) of the steering system on many heavy trucks and some older vehicles. Understanding its workings is vital for several reasons:

- Repair and Maintenance: Diagnosing and fixing issues like steering slop, excessive tire wear, and wandering require a solid grasp of the king pin assembly.

- Front-End Alignment: The king pin angle (KPI), also known as steering axis inclination (SAI), is a critical alignment parameter. Knowing how the king pin affects this angle is essential for accurate alignment.

- Safety: A worn or damaged king pin can lead to serious steering instability, making it a significant safety hazard.

- Modification and Upgrades: If you're modifying a truck or considering upgraded steering components, you need to understand how the king pin interacts with the overall system.

Having a good grasp of the king pin assembly can empower you to perform preventative maintenance, diagnose problems early, and make informed decisions about repairs or modifications. Furthermore, it will save you money in the long run.

Key Specs and Main Parts

The king pin assembly is a relatively simple but robust design. The basic components include:

- King Pin: The hardened steel pin itself, which acts as a pivot point. It passes through the spindle (or knuckle) and the axle.

- Spindle (or Knuckle): The spindle houses the wheel hub and bearings. It rotates around the king pin, allowing the wheels to steer.

- Axle: The main structural component that supports the vehicle's weight and transmits power to the wheels (in a driven axle). The king pin connects the spindle to the axle.

- Bushings (or Bearings): Located between the spindle and the axle, these bushings or bearings allow the spindle to rotate smoothly around the king pin, reducing friction and wear. Common materials include bronze, nylon, or needle roller bearings.

- King Pin Lock Bolt: A fastener that secures the king pin in place, preventing it from rotating or backing out.

- Grease Fittings (Zerk Fittings): These fittings allow you to lubricate the king pin assembly, reducing friction and preventing corrosion.

- Thrust Bearings (or Washers): Located at the top and bottom of the spindle, these bearings or washers support the vertical load and allow the spindle to rotate freely.

Key Specs you'll typically encounter include:

- King Pin Diameter: The diameter of the king pin itself, which affects its strength and load-carrying capacity.

- King Pin Length: The overall length of the king pin, which must be compatible with the axle and spindle dimensions.

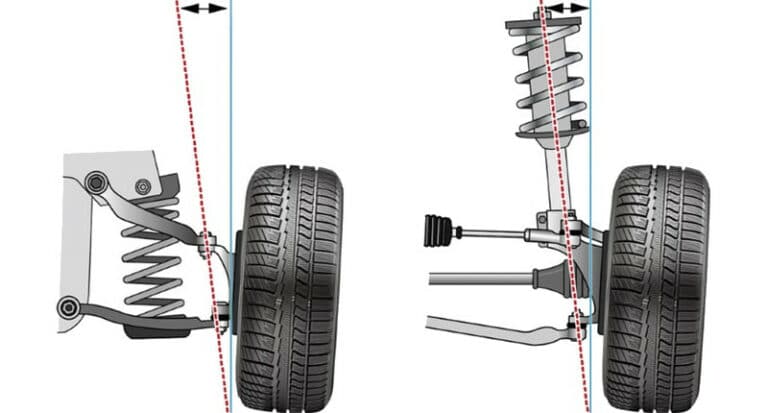

- King Pin Angle (KPI/SAI): The angle of the king pin relative to vertical. This angle affects steering feel, stability, and tire wear.

How It Works

The king pin assembly functions as a hinge, allowing the front wheels to pivot for steering. Here's a breakdown of the process:

- Steering Input: When the driver turns the steering wheel, the motion is transmitted through the steering linkage to the steering arm (also known as the Pitman arm).

- Spindle Rotation: The steering arm pushes or pulls on the spindle, causing it to rotate around the king pin.

- Wheel Pivoting: As the spindle rotates, the attached wheel pivots, changing the vehicle's direction.

- King Pin as the Pivot: The king pin acts as the central pivot point for this rotation, allowing the spindle and wheel to move freely.

- Bushings/Bearings Facilitate Movement: The bushings or bearings between the spindle and the axle minimize friction, ensuring smooth and responsive steering.

The King Pin Inclination (KPI) plays a critical role in steering feel and stability. KPI, also known as Steering Axis Inclination (SAI), is the angle between the kingpin axis and a vertical line when viewed from the front of the vehicle. When the wheel is turned away from the straight-ahead position, the vehicle weight forces the suspension to slightly lift the vehicle. This lifting action creates a self-centering effect that tends to return the wheels to the straight-ahead position. This helps with steering stability and reduces steering effort.

Real-World Use - Basic Troubleshooting

Here are some common problems associated with king pins and how to diagnose them:

- Steering Slop: Excessive play in the steering wheel before the wheels respond. This can indicate worn king pin bushings or a loose king pin lock bolt.

- Wandering: The vehicle tends to drift from side to side, requiring constant steering corrections. Worn king pin bushings or an improperly adjusted king pin angle can cause this.

- Uneven Tire Wear: Unusual wear patterns on the front tires, such as feathering or cupping, can be a sign of alignment issues related to the king pin angle.

- Difficulty Steering: Stiff or difficult steering can indicate a lack of lubrication in the king pin assembly or seized bushings/bearings.

Basic Troubleshooting Steps:

- Visual Inspection: Check for any visible signs of wear, damage, or looseness in the king pin assembly. Look for grease leaking from the bushings.

- "Dry Park" Steering Test: With the vehicle parked on a level surface, have someone turn the steering wheel back and forth while you observe the king pin assembly for any excessive play or movement.

- Grease Check: Ensure the king pin assembly is properly lubricated. If it's difficult to pump grease into the fittings, the bushings may be clogged or seized.

- Professional Inspection: If you suspect a problem with your king pins, it is always recommended to have a qualified mechanic inspect the assembly, especially if your vehicle is critical for your livelihood.

Safety Considerations

Working on king pin assemblies can be dangerous due to the high loads and the potential for components to be under tension. Always follow these safety precautions:

- Use Proper Lifting Equipment: Never work under a vehicle supported only by a jack. Use sturdy jack stands to support the axle.

- Wear Safety Glasses: Protect your eyes from flying debris.

- Use Proper Tools: Use the correct tools for the job to avoid damaging components or injuring yourself. A king pin press is often required for removal and installation.

- Relieve Spring Tension: Before disassembling the king pin assembly, ensure that any spring tension is relieved to prevent sudden release and potential injury.

- Handle Springs with Care: Coil springs and leaf springs can store a significant amount of energy. Use spring compressors or other appropriate tools to safely handle them.

- Work in a Well-Ventilated Area: When using solvents or cleaning products, work in a well-ventilated area to avoid inhaling harmful fumes.

Risky Components:

- Springs: As mentioned above, these can be incredibly dangerous if released unexpectedly.

- Heavy Components: Axles, spindles, and wheels are very heavy. Ensure you have adequate lifting equipment and assistance when handling them.

- Press-Fit Components: Removing and installing king pins often requires a hydraulic press. Improper use of a press can damage components or cause injury.

By understanding the function, components, and potential hazards of the king pin assembly, you can confidently approach repairs, maintenance, and modifications with a focus on safety and accuracy.