What Is A Manual Transmission Car

Welcome, fellow gearheads! Let's dive deep into the fascinating world of manual transmissions. Whether you're wrenching on your own ride, considering a performance upgrade, or just want to understand the inner workings of your car better, understanding the manual transmission is a crucial skill. This article aims to give you that detailed, technical understanding.

Purpose: Why This Knowledge Matters

Understanding the manual transmission goes far beyond just knowing how to drive one. Having a firm grasp on its components and operation will empower you to:

- Diagnose problems accurately: Instead of relying solely on guesswork, you can pinpoint the root cause of issues like slipping gears, difficulty shifting, or unusual noises.

- Perform basic maintenance: Simple tasks like changing the transmission fluid become less daunting and more confidence-inspiring.

- Upgrade your transmission: Considering a performance clutch, short shifter, or even a complete transmission swap? Understanding the fundamentals will help you make informed decisions and avoid costly mistakes.

- Safely operate your vehicle: Knowledge is power. Knowing how the transmission works in relation to the engine and driveline helps you drive more efficiently and safely.

Key Specs and Main Parts

The heart of a manual transmission is its gears. These gears are what multiply the engine's torque to move the vehicle and determine the speed at which the wheels turn relative to the engine's speed. Here's a breakdown of the key components:

Main Components:

- Input Shaft: This shaft receives power directly from the engine via the clutch. It spins at the same rate as the engine when the clutch is engaged.

- Clutch: The crucial link between the engine and the transmission. When engaged, it transmits engine power; when disengaged, it allows the engine to run independently of the transmission. (We'll discuss clutch specifics separately in another article.)

- Gears: A series of meshing gears of varying sizes. Different gear ratios provide different levels of torque multiplication and speed reduction. Common configurations include 5-speed, 6-speed, and occasionally even more gears.

- Countershaft (or Lay Shaft): A shaft that runs parallel to the main shaft, containing a set of gears permanently meshed with the gears on the main shaft. It's driven by the input shaft and in turn drives the output shaft gears.

- Output Shaft: The shaft that transmits power from the transmission to the driveshaft (or axles in a front-wheel-drive car) and ultimately to the wheels.

- Shift Forks: Mechanical levers that move the synchronizers to engage the desired gear.

- Synchronizers (Synchros): These are crucial components that bring the speed of the selected gear's hub and the output shaft to the same speed before the gear is fully engaged. This prevents grinding and makes shifting smoother. Think of them as miniature clutches for the gears.

- Shift Linkage: The system of rods, cables, or levers that connect the gearshift lever in the cabin to the shift forks inside the transmission.

- Transmission Housing: The protective casing that encloses all the internal components, filled with transmission fluid for lubrication and cooling.

Key Specs: While internal gear ratios are highly vehicle-specific, some general specifications to consider are:

- Gear Ratios: Expressed as a ratio (e.g., 3.5:1), indicating how many times the input shaft rotates for each rotation of the output shaft. Lower gears (higher numerical ratio) provide more torque for acceleration, while higher gears (lower numerical ratio) offer better fuel economy and lower engine speeds at cruising speeds.

- Overall Gear Ratio: The combined ratio of the transmission and the final drive (differential) gear. This determines the final torque multiplication at the wheels.

- Transmission Fluid Capacity: The amount of fluid required to properly lubricate the transmission. This is crucial for maintaining optimal performance and preventing damage.

- Torque Capacity: The maximum amount of torque the transmission can handle without failure. Important when considering engine modifications or racing applications.

How It Works: A Step-by-Step Explanation

The magic of a manual transmission lies in its ability to manipulate the engine's output to suit the driving conditions. Here's a breakdown of the process:

- Power Input: The engine's crankshaft spins, transferring power to the clutch assembly.

- Clutch Engagement/Disengagement: When the clutch pedal is released (clutch engaged), the clutch disc is pressed against the flywheel, transmitting the engine's rotation to the input shaft of the transmission. Pressing the clutch pedal disengages the clutch, disconnecting the engine from the transmission.

- Gear Selection: The driver uses the gearshift lever to select the desired gear. This action moves the shift linkage, which in turn moves the shift forks inside the transmission.

- Synchronizer Engagement: The shift fork pushes the synchronizer towards the gear selected. The synchronizer uses friction to equalize the speed of the gear and the output shaft.

- Gear Engagement: Once the speeds are synchronized, the synchronizer sleeve slides further, locking the selected gear to the output shaft. Now, the power flows from the input shaft, through the selected gearset (involving the countershaft), to the output shaft.

- Power Output: The output shaft transmits the multiplied torque to the driveshaft (or axles), which then turns the wheels.

The ratio of the engaged gears determines the amount of torque multiplication and speed reduction. For example:

"A lower gear (e.g., first gear) provides a high gear ratio, resulting in significant torque multiplication for acceleration from a standstill. A higher gear (e.g., fifth or sixth gear) provides a lower gear ratio, resulting in less torque multiplication but higher speeds and better fuel economy."

Real-World Use: Basic Troubleshooting Tips

While a manual transmission can be incredibly reliable, problems can arise. Here are a few common issues and how to address them:

- Difficulty Shifting:

- Possible Cause: Clutch not fully disengaging, worn synchronizers, low transmission fluid, damaged shift linkage.

- Troubleshooting: Check clutch cable/linkage adjustment, inspect shift linkage for looseness, check transmission fluid level and condition. If those check out, worn synchros are likely.

- Grinding Gears:

- Possible Cause: Worn synchronizers, clutch not fully disengaging, incorrect shifting technique.

- Troubleshooting: Ensure the clutch is fully disengaging, consider using a heavier weight transmission fluid, and be more deliberate with your shifts. This usually indicates synchro wear.

- Slipping Gears:

- Possible Cause: Worn or damaged gears, low transmission fluid, worn synchronizers.

- Troubleshooting: Check transmission fluid level and condition. Slipping generally indicates internal wear and tear, often requiring professional inspection and repair.

- Unusual Noises:

- Possible Cause: Low transmission fluid, worn bearings, damaged gears.

- Troubleshooting: Check transmission fluid level and condition. Unusual noises often indicate internal damage and require professional diagnosis.

Safety: Handle with Care

Working on a manual transmission involves certain risks. Always take the following precautions:

- Support the Vehicle Securely: Use jack stands to support the vehicle before working underneath it. Never rely solely on a jack.

- Wear Safety Glasses: Protect your eyes from flying debris and chemicals.

- Use Proper Tools: Using the wrong tools can damage components and cause injury.

- Be Mindful of Hot Surfaces: The exhaust system and transmission can get extremely hot. Allow them to cool before working near them.

- Transmission Fluid Disposal: Dispose of used transmission fluid properly at a recycling center.

- Rotating components: Never operate the vehicle with the transmission exposed. The gears and shafts are dangerous when spinning.

- Springs: Be careful when disassembling the transmission. Some components have springs that can cause injury if released improperly.

Clutch Specific Risks: The clutch assembly contains a powerful spring. Improper removal can lead to serious injury. Consult a repair manual and use a clutch alignment tool to safely remove and install the clutch.

We hope this detailed overview has helped you understand the intricacies of a manual transmission. Remember, this is a complex system, and proper knowledge and caution are essential for successful repairs and modifications. Happy wrenching!

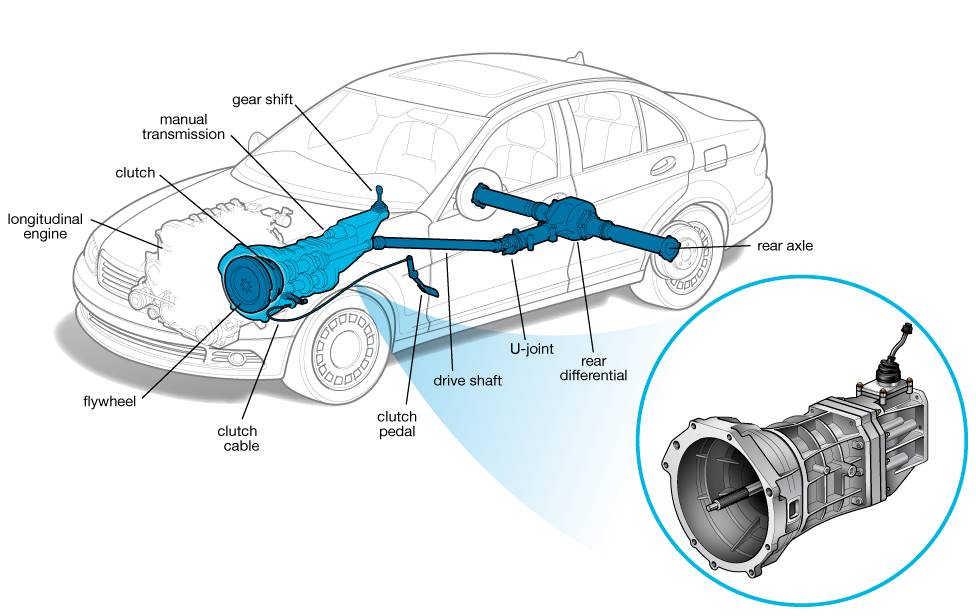

We have a detailed diagram of a typical manual transmission assembly available for download. This will provide a visual aid to complement the information presented in this article. You can [Link to Download] to obtain the file.