What Is A Master Brake Cylinder

Let's talk about the unsung hero of your braking system: the master cylinder. This component is absolutely crucial for your safety, and understanding how it works can empower you to diagnose problems, perform basic maintenance, and even upgrade your braking system with confidence. Whether you're tackling a brake job, considering a performance brake upgrade, or just want to know your car better, grasping the master cylinder's function is essential. We’re going to dive deep, but I'll keep it approachable, like having a conversation in your garage.

Key Specs and Main Parts

The master cylinder is a hydraulic pump that converts mechanical force (from your foot on the brake pedal) into hydraulic pressure. This pressure is then transmitted through brake lines to the wheel cylinders or calipers, forcing the brake pads against the rotors (or shoes against the drums) and slowing your vehicle.

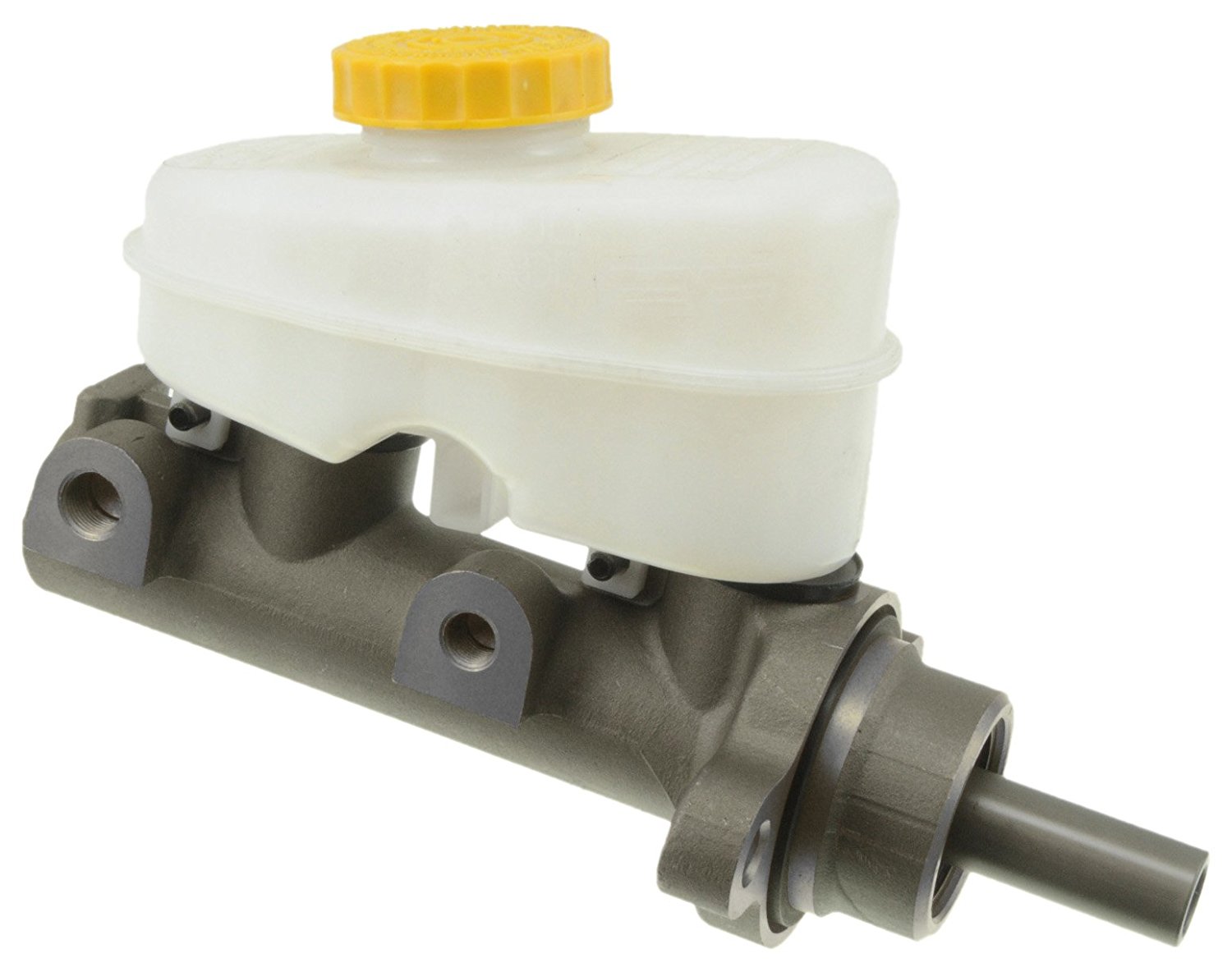

Here are the main parts you'll find in a typical master cylinder:

- Cylinder Body: This is the main housing, typically made of cast iron or aluminum. It contains the internal components and provides mounting points.

- Reservoir: This is the container that holds the brake fluid. It usually has two chambers, one for the front brakes and one for the rear. This dual-chamber design is a crucial safety feature, as we'll discuss later.

- Piston(s): The piston(s) are pushed by the pushrod (connected to the brake pedal). As the piston(s) move within the cylinder bore, they displace brake fluid, creating pressure. Most modern cars use a dual-piston (tandem) master cylinder for added safety.

- Primary and Secondary Seals (Cups): These rubber seals are located on the pistons and prevent brake fluid from leaking past. They're critical for maintaining pressure within the hydraulic system.

- Pushrod: Connects the brake pedal to the master cylinder piston. Its length and adjustment are vital for proper brake function and pedal feel.

- Residual Pressure Valves (Check Valves): Some older or drum brake systems incorporate these valves to maintain a small amount of pressure in the brake lines when the brakes are released. This helps to keep the brake shoes close to the drums and reduces pedal travel.

- Outlet Ports: These are the threaded openings where the brake lines connect to the master cylinder. One port typically serves the front brakes, and the other serves the rear brakes (or one port per front brake on some performance systems).

Common Master Cylinder Specifications

While the exact specifications will vary depending on your vehicle, some common parameters include:

- Bore Size: This refers to the diameter of the cylinder bore where the piston(s) move. A larger bore size will displace more fluid with each stroke, potentially increasing braking force but also requiring more pedal travel.

- Stroke Length: The distance the piston travels within the cylinder.

- Outlet Port Thread Size: You need to know these when replacing brake lines or fittings.

- Reservoir Capacity: How much brake fluid the reservoir holds. Important for bleeding the brakes.

How It Works

The operation of the master cylinder is relatively straightforward. When you press the brake pedal, the pushrod applies force to the primary piston in the master cylinder. This piston moves within the bore, compressing the brake fluid in front of it. This creates pressure in the primary brake circuit, usually connected to the front brakes.

As the primary piston moves, it also pushes on the secondary piston. This secondary piston then compresses the brake fluid in the secondary brake circuit, usually connected to the rear brakes. This dual-piston (tandem) design is crucial for safety. If one circuit fails (e.g., a brake line ruptures), the other circuit will still provide braking power, although reduced.

When you release the brake pedal, the return springs push the pistons back to their original positions. This relieves the pressure in the brake lines, allowing the brake calipers or wheel cylinders to retract and release the brakes. As the pistons return, brake fluid flows from the reservoir to refill the cylinder bore, preparing it for the next braking cycle.

Real-World Use: Basic Troubleshooting Tips

Knowing how the master cylinder works can help you diagnose common braking problems:

- Spongy Brake Pedal: This can be caused by air in the brake lines, a failing master cylinder, or worn brake pads. If bleeding the brakes doesn't solve the problem, the master cylinder might be leaking internally, allowing fluid to bypass the piston(s).

- Brake Pedal Goes to the Floor: This is a serious problem and indicates a major loss of hydraulic pressure. It could be due to a ruptured brake line, a leaking wheel cylinder or caliper, or a completely failed master cylinder. Do not drive the vehicle until the problem is resolved.

- Brake Fluid Loss: Check the master cylinder reservoir for low fluid levels. If the level is consistently dropping, inspect the master cylinder for external leaks. Also, check the brake lines, calipers, and wheel cylinders for leaks.

- Brakes Dragging: While not always the master cylinder, a stuck or partially blocked compensating port in the master cylinder can prevent the brakes from fully releasing. This is less common but possible.

Bleeding the Master Cylinder: Whenever you replace the master cylinder, you need to bleed it to remove air from the internal passages. This is usually done by bench bleeding (bleeding the master cylinder while it's removed from the vehicle) or by pressure bleeding (using a specialized tool to force fluid through the system). Always follow the manufacturer's instructions for your specific vehicle.

Safety: Highlight Risky Components

The braking system is critical for your safety. Working on it requires caution and attention to detail.

- Brake Fluid: Brake fluid is corrosive and can damage paint and other surfaces. Wear gloves and eye protection when handling it. Dispose of used brake fluid properly according to local regulations. Also, different types of brake fluid (DOT 3, DOT 4, DOT 5) have different properties and are not always compatible. Use the type specified in your vehicle's owner's manual or service manual.

- Pressure: The hydraulic pressure in the braking system can be very high. Never disconnect brake lines while the system is pressurized. Always depressurize the system by pumping the brake pedal several times with the engine off before working on the brakes.

- Contamination: Even a small amount of dirt or debris in the brake system can cause problems. Keep all parts clean and use new brake fluid when refilling the system.

- Air in the System: Air in the brake lines will make the brakes feel spongy and reduce their effectiveness. Bleed the brakes thoroughly after any work on the hydraulic system.

- Pushrod Adjustment: Incorrect pushrod adjustment can prevent the brakes from fully releasing or cause excessive wear on the master cylinder. Consult your vehicle's service manual for the proper adjustment procedure.

Symbols Explained

A schematic diagram of the master cylinder will use common symbols to represent the various components and fluid paths. Here are some typical symbols you might encounter:

- Lines: Solid lines represent brake lines (hydraulic fluid paths). Dashed lines often indicate vacuum lines (if the system uses a vacuum booster).

- Circles: Often represent pistons or seals.

- Rectangles: Can represent valves or other components.

- Springs: Zigzag lines represent springs.

- Triangles: Sometimes used to indicate pressure points or fluid inlets/outlets.

- Colors: Colors are often used to differentiate between different circuits or types of fluid. For example, blue might represent brake fluid, while red might represent air pressure.

Pay close attention to the direction of arrows in the diagram. These indicate the direction of fluid flow. Also, note the orientation of the components. This will help you understand how they interact with each other.

Remember, this is just a general overview. Specific designs and features can vary depending on the vehicle manufacturer and model. Always consult your vehicle's service manual for detailed information about your braking system.

This information should give you a solid understanding of the master cylinder. Remember to prioritize safety and consult your service manual for specific procedures related to your vehicle. Happy wrenching!