What Is A Multi Point Inspection

Alright, let's talk about Multi-Point Inspections (MPIs). You’ve probably heard of them, maybe even had one done on your vehicle. But what exactly are they? And why should you, as someone who likes to get their hands dirty under the hood, care? This article is going to break down the MPI, explain what it involves, and arm you with the knowledge to either perform a competent one yourself or better understand what a professional mechanic is doing.

Purpose of a Multi-Point Inspection

The core purpose of a Multi-Point Inspection is preventative maintenance. Think of it as a comprehensive health check for your car. It's not meant to diagnose specific issues necessarily, but rather to identify potential problems before they become major (and expensive) headaches. An MPI is useful for:

- Preventing Breakdowns: Catching wear and tear early reduces the likelihood of unexpected failures.

- Extending Vehicle Lifespan: Regular inspections help maintain all vehicle systems, contributing to its overall longevity.

- Improving Safety: Identifying safety-related issues like brake wear or tire condition helps keep you safe on the road.

- Maintaining Resale Value: A well-maintained vehicle with documented inspections is more attractive to potential buyers.

- Planning Maintenance: An MPI report provides a roadmap for future maintenance, allowing you to budget and schedule accordingly.

For the experienced DIYer, performing your own MPI allows you to stay ahead of the curve, address issues proactively, and save money on costly repairs down the line. Plus, it gives you a much deeper understanding of your vehicle's condition.

Key Specs and Main Parts of an MPI

An MPI covers a wide range of components and systems. While the exact checklist can vary slightly between shops, a typical MPI will include inspections of the following areas:

- Engine:

- Fluid Levels: Oil, coolant, power steering fluid, brake fluid, windshield washer fluid. Ensuring these are within their specified ranges (refer to your vehicle's owner's manual for those ranges).

- Leaks: Checking for any visible leaks of oil, coolant, or other fluids. Pay close attention to seals and gaskets.

- Belts and Hoses: Inspecting for cracks, wear, or damage. A failing serpentine belt can leave you stranded.

- Visual Inspection: Checking for unusual noises, vibrations, or smells.

- Brakes:

- Brake Pads/Shoes: Measuring the thickness of brake pads or shoes. A minimum thickness is typically specified (check your vehicle's repair manual).

- Rotors/Drums: Inspecting for scoring, cracks, or warping.

- Brake Lines and Hoses: Checking for leaks, corrosion, or damage. These are critical for safe braking.

- Brake Fluid: Checking the condition of the brake fluid. Over time, brake fluid can absorb moisture, which can reduce braking performance.

- Tires:

- Tire Pressure: Checking and adjusting tire pressure to the recommended level (found on the tire placard on the driver's side doorjamb).

- Tread Depth: Measuring tread depth using a tread depth gauge. Most jurisdictions have minimum legal tread depth requirements.

- Tire Condition: Inspecting for cuts, bulges, or uneven wear.

- Suspension and Steering:

- Shocks and Struts: Inspecting for leaks or damage.

- Ball Joints and Tie Rod Ends: Checking for play or looseness.

- Steering Components: Inspecting for wear or damage.

- Lights:

- Headlights, Taillights, Brake Lights, Turn Signals: Ensuring all lights are functioning properly.

- Battery:

- Battery Condition: Testing the battery's voltage and capacity.

- Battery Terminals: Cleaning any corrosion from the battery terminals.

- Exhaust System:

- Exhaust Leaks: Inspecting for leaks in the exhaust system.

- Muffler and Catalytic Converter: Checking for damage or corrosion.

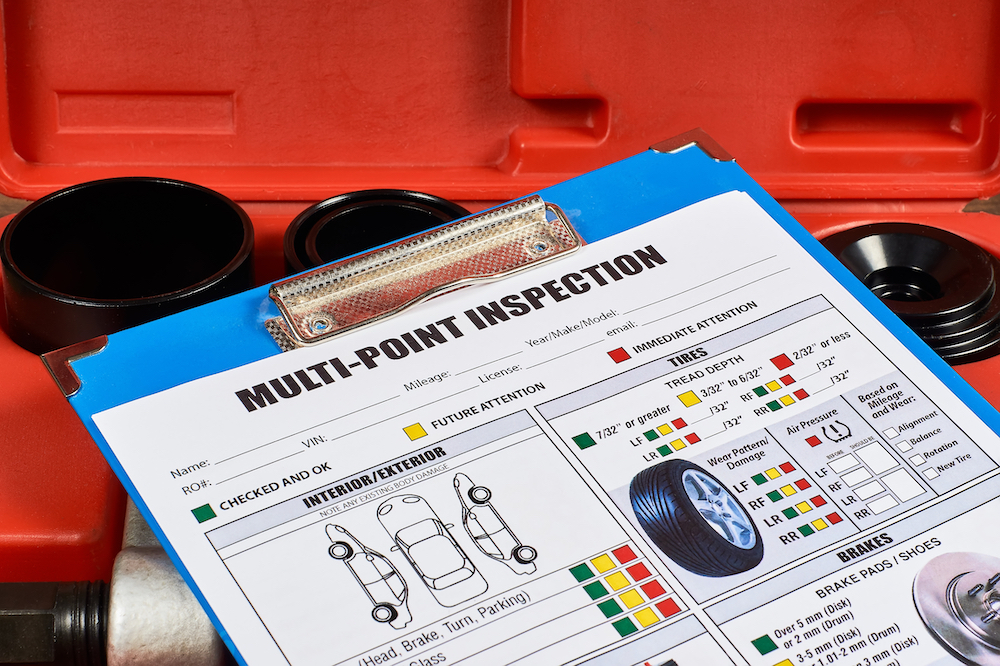

"Diagram" Explanation: Understanding Inspection Reports

While there isn't a single "diagram" for an MPI in the same way there's a wiring diagram, the inspection report itself is a visual representation of your vehicle's condition. Think of it as a health report card. Here's how to interpret it:

- Color Coding: Most MPI reports use a color-coding system to indicate the severity of any issues found. Common colors include:

- Green: Indicates that the component is in good condition.

- Yellow: Indicates that the component is showing signs of wear and may need attention soon.

- Red: Indicates that the component is in need of immediate repair or replacement.

- Symbols/Icons: Some reports may use icons to represent different components or systems. The meaning of these icons should be explained in the report's legend.

- Measurements: The report will typically include measurements for things like brake pad thickness, tire tread depth, and battery voltage. These measurements provide a more objective assessment of the component's condition.

- Notes: Pay close attention to any notes or comments provided by the inspector. These notes may provide additional details about any issues found.

The format and level of detail in an MPI report can vary depending on the shop, but the core principles remain the same: to provide a clear and concise overview of your vehicle's condition.

How It Works: Performing the Inspection

Now let's get practical. Here’s the general procedure for performing a DIY Multi-Point Inspection. Remember, safety first!

- Gather Your Tools: You'll need basic hand tools, a tire pressure gauge, a tread depth gauge, a flashlight, a creeper (optional), and a notebook to record your findings.

- Prepare Your Vehicle: Park your vehicle on a level surface and engage the parking brake. Allow the engine to cool down completely before starting the inspection.

- Follow the Checklist: Use a pre-printed MPI checklist or create your own. Work systematically through each item on the list, inspecting each component carefully.

- Document Your Findings: Record your observations in your notebook. Be specific and detailed in your notes. Include measurements where applicable.

- Prioritize Repairs: Once you've completed the inspection, review your findings and prioritize any necessary repairs. Address critical safety issues first.

Important Note: If you're not comfortable performing any of these tasks, it's best to leave them to a qualified mechanic.

Real-World Use: Basic Troubleshooting Tips

Let's say you've performed an MPI and found some issues. Here are a few basic troubleshooting tips:

- Low Coolant Level: Check for leaks in the cooling system, including the radiator, hoses, water pump, and thermostat housing. A pressure test can help identify hard-to-find leaks.

- Worn Brake Pads: Replace the brake pads and resurface or replace the rotors. Follow the manufacturer's instructions carefully.

- Low Tire Tread: Replace the tires. Consider replacing all four tires at the same time to maintain optimal handling and braking performance.

- Battery Corrosion: Clean the battery terminals with a battery terminal cleaner. Consider replacing the battery if it's old or showing signs of weakness.

Remember, these are just basic troubleshooting tips. More complex issues may require the expertise of a qualified mechanic.

Safety – Highlight Risky Components

Working on vehicles can be dangerous. Always prioritize safety. Here are a few specific safety considerations related to MPIs:

- Braking System: The brake system is critical for safety. If you're not comfortable working on the brakes, leave it to a professional. Improper brake repairs can lead to serious accidents.

- Electrical System: The electrical system can be dangerous, especially the battery. Disconnect the negative battery cable before working on any electrical components.

- Exhaust System: The exhaust system can be extremely hot. Allow the exhaust system to cool down completely before inspecting it. Exhaust fumes are also toxic, so work in a well-ventilated area.

- Jacking and Lifting: Always use jack stands when working under a vehicle. Never rely solely on a jack to support the weight of the vehicle.

- Fluids: Many automotive fluids are toxic or flammable. Wear gloves and eye protection when handling fluids. Dispose of used fluids properly.

By understanding the purpose and process of a multi-point inspection, you’re better equipped to maintain your vehicle, identify potential problems, and make informed decisions about repairs. Remember to always prioritize safety, and when in doubt, consult a qualified mechanic.

We have a sample MPI form/checklist available. You can download it to help guide your own inspections.