What Is A Rocker Arm In A Car

Hey gearheads! Today, we're diving deep into the heart of your engine to explore a crucial component: the rocker arm. This guide is designed for you, the intermediate car owner, the budding modder, the weekend wrench turner. We'll break down its function, construction, troubleshooting, and safety considerations, all with the goal of empowering you to better understand and maintain your engine. Understanding the rocker arm is important because it's a frequent source of valve train noise and performance issues. Knowing how it works, and how to diagnose problems, can save you money and improve your engine's performance.

What is a Rocker Arm and Why Should You Care?

The rocker arm is a critical component in the valve train of an internal combustion engine. Its primary function is to translate the rotary motion of the camshaft into the linear motion needed to open and close the engine's valves. In essence, it acts as a lever, amplifying the relatively small movement of the cam lobe into a larger movement at the valve stem.

Why should you care? Because worn or damaged rocker arms can lead to a host of problems, including:

- Reduced engine performance: Incorrect valve timing due to worn rocker arms directly impacts the engine's ability to breathe efficiently.

- Increased engine noise: Ticking, clicking, or clattering sounds often indicate worn rocker arms or excessive valve lash (the clearance between the rocker arm and the valve stem).

- Poor fuel economy: Inefficient valve operation can lead to incomplete combustion and wasted fuel.

- Engine damage: In severe cases, a failed rocker arm can cause valve float (the valve doesn't fully close), piston-to-valve contact, and catastrophic engine damage.

Therefore, understanding the rocker arm is crucial for preventative maintenance, troubleshooting engine issues, and potentially upgrading your engine for better performance.

Key Specs and Main Parts

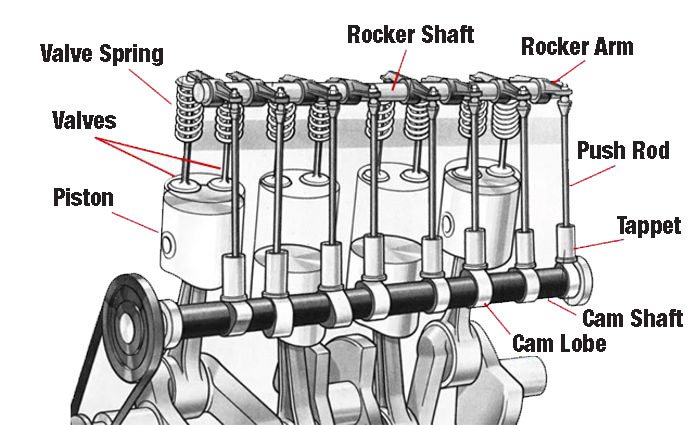

Let's dissect the rocker arm and examine its core components and specifications.

Main Parts:

- Rocker Arm Body: This is the main structural component, typically made of forged steel, cast iron, or aluminum. The material selection depends on the engine's performance requirements.

- Cam Follower (or Rocker Arm Pad): The surface that directly contacts the camshaft lobe. It can be a roller bearing (roller rocker arm) or a simple hardened pad. Roller followers reduce friction and wear, improving engine efficiency and power.

- Valve Stem Contact Point: The area where the rocker arm pushes down on the valve stem to open the valve. Often, an adjustable screw (pushrod engines) or shim (overhead cam engines) is located here to set the valve lash.

- Pivot Point: The point where the rocker arm pivots. This can be a shaft (shaft-mounted rocker arms) or a fulcrum (pedestal-mounted rocker arms).

- Oil Hole/Passage: Many rocker arms have internal oil passages to lubricate the cam follower and valve stem contact point. Proper lubrication is critical to prevent wear and failure.

Key Specs:

- Rocker Arm Ratio: This is the ratio of the distance from the pivot point to the cam follower versus the distance from the pivot point to the valve stem contact point. A higher rocker arm ratio increases valve lift for a given cam lobe profile, potentially improving engine performance. Common ratios are 1.5:1, 1.6:1, and 1.7:1.

- Valve Lash (or Valve Clearance): The specified gap between the rocker arm and the valve stem when the valve is closed. This clearance is necessary to accommodate thermal expansion. Incorrect valve lash can lead to noise, performance issues, and valve damage.

- Material: As mentioned above, the material affects the rocker arm's strength, durability, and weight. High-performance engines often use lighter, stronger materials like aluminum or titanium.

How It Works

The rocker arm's operation is relatively straightforward. As the camshaft rotates, the cam lobe pushes against the cam follower on the rocker arm. This force causes the rocker arm to pivot around its pivot point. The opposite end of the rocker arm, the valve stem contact point, then pushes down on the valve stem, opening the valve. When the cam lobe rotates away, the valve spring closes the valve, and the rocker arm returns to its resting position.

In pushrod engines, the camshaft is located in the engine block, and a pushrod transfers the cam lobe's motion to the rocker arm. In overhead cam (OHC) engines, the camshaft is located in the cylinder head, directly above the valves, eliminating the need for pushrods. OHC engines typically use finger followers or bucket tappets, which are variations of the rocker arm design.

Real-World Use: Basic Troubleshooting Tips

Here are some common problems you might encounter and how to troubleshoot them:

- Ticking/Clicking Noise: Often caused by excessive valve lash. Check and adjust the valve lash according to the manufacturer's specifications. Worn rocker arm pads or rollers can also cause noise.

- Clattering Noise: May indicate a loose or damaged rocker arm. Inspect the rocker arm for cracks, wear, or looseness. Check the pivot point for wear.

- Reduced Engine Performance: Could be due to worn cam lobes or rocker arm pads. Perform a compression test to rule out valve issues. Inspect the rocker arms for excessive wear or damage.

- Oil Leaks: Check the valve cover gaskets and rocker arm seals for leaks.

Important: Always consult your vehicle's service manual for specific troubleshooting procedures and torque specifications.

Safety – Highlight Risky Components

Working on the valve train involves dealing with several potential hazards:

- Spring Pressure: Valve springs store a significant amount of energy. Use the correct valve spring compressor tool to safely remove and install valve springs. Improper tool use can result in serious injury.

- Hot Engine Components: Allow the engine to cool completely before working on the valve train. Exhaust manifolds and other components can remain hot for a long time.

- Rotating Parts: Never start the engine with the valve cover removed. Rotating parts like the camshaft and rocker arms can cause serious injury.

- Eye Protection: Always wear safety glasses when working on the engine to protect your eyes from flying debris.

- Oil: Be mindful of hot oil, which could cause burns.

Always disconnect the negative battery cable before working on any electrical or mechanical components of your vehicle. This will prevent accidental electrical shocks or damage to the vehicle's electrical system.

Final Thoughts: Understanding the rocker arm is a fundamental aspect of engine maintenance and performance tuning. By grasping its function, construction, and troubleshooting techniques, you can better diagnose and address valve train issues, ensuring your engine runs smoothly and efficiently.