What Is A Stage 3 Clutch

So, you're thinking about upgrading your clutch, and the term "Stage 3 clutch" keeps popping up? Let's break down exactly what that means. This isn't just some marketing buzzword; it represents a significant step up in performance capability, but it also comes with trade-offs. Consider this your in-depth guide to understanding Stage 3 clutches, from their components to their real-world applications.

Understanding the Purpose

Before we dive into the specifics, let's talk about why understanding this matters. Whether you're planning a high-horsepower build, experiencing clutch slip in your modified vehicle, or simply curious about performance upgrades, knowing the ins and outs of a Stage 3 clutch is crucial. This knowledge will help you make informed decisions about parts selection, installation, and troubleshooting. A detailed understanding also allows you to better communicate with shops and ensure you're getting the right solution for your needs. Furthermore, if you plan on doing the install yourself, comprehending the operation is paramount to a successful and safe job. We're essentially giving you the knowledge to prevent costly mistakes and potentially dangerous situations.

Key Specs and Main Parts of a Stage 3 Clutch

A Stage 3 clutch is typically designed for vehicles with significantly increased horsepower and torque. The goal is to provide a higher clamping force than a stock or Stage 1/2 clutch, preventing slippage under demanding conditions. Here are the key components and their characteristics:

1. Pressure Plate

The pressure plate is a critical component. Stage 3 pressure plates typically feature a significantly increased clamping force, often expressed as a percentage over stock (e.g., +50% clamping force). This increased force is achieved through stronger springs and a modified design. The type of pressure plate (diaphragm or coil spring) will influence its feel and responsiveness. Some Stage 3 clutches utilize a modified diaphragm spring, which is common to provide a balance of higher clamp load and reasonable pedal effort. Expect a stiffer pedal feel compared to stock.

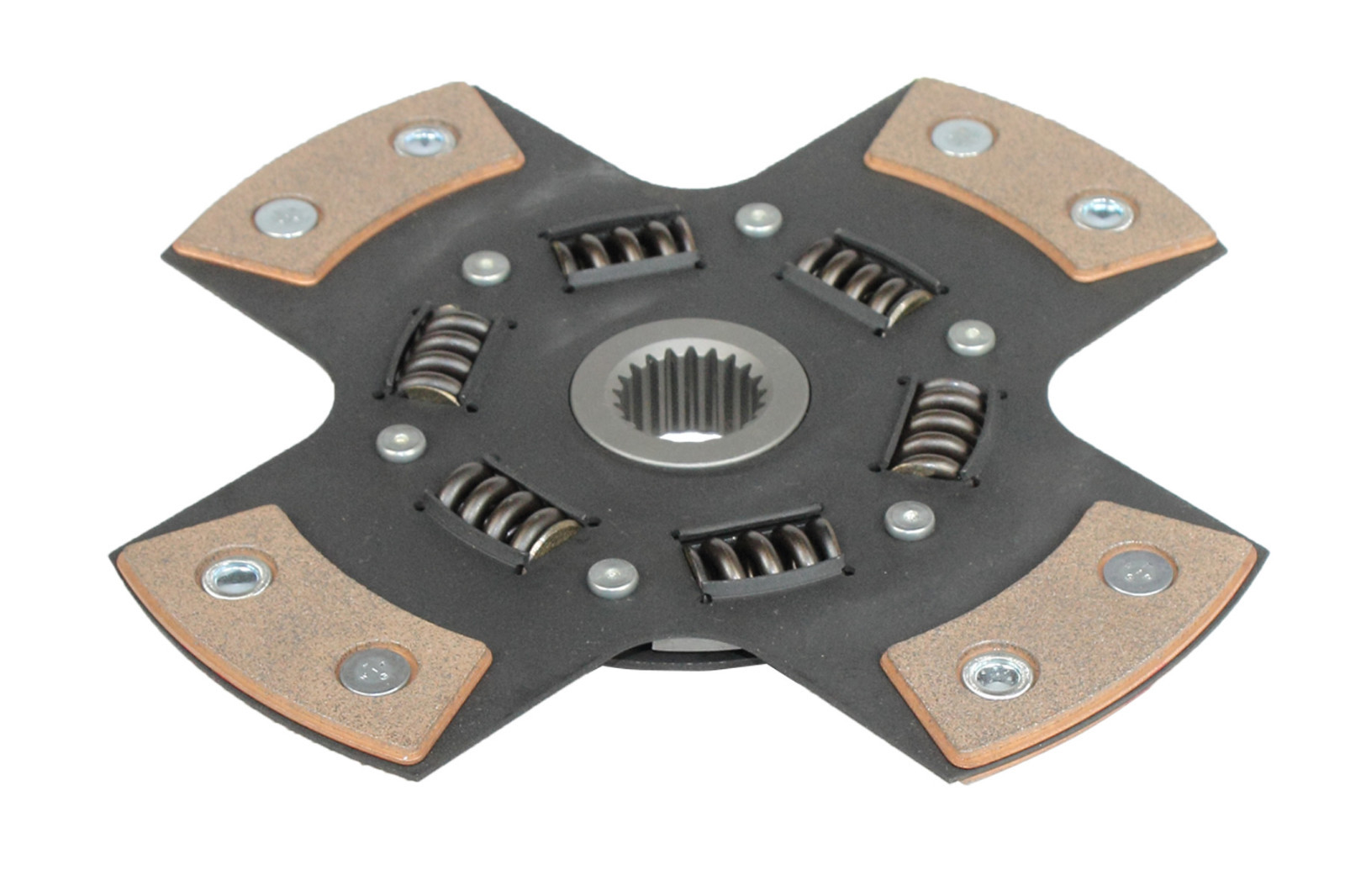

2. Clutch Disc

The clutch disc is where the friction happens. Stage 3 clutch discs are often made of materials that can withstand higher temperatures and offer a higher coefficient of friction. Common materials include:

- Ceramic/Sintered Iron: Offers the highest coefficient of friction and heat resistance but can be aggressive and less forgiving, leading to chatter and difficult drivability in everyday situations. Expect a shorter lifespan if driven harshly.

- Kevlar: Provides a good balance of friction, heat resistance, and drivability. It is generally smoother than ceramic and less prone to chatter, but it may not hold as much power as a ceramic disc.

- Hybrid (e.g., Ceramic/Organic): Combines the benefits of both materials for a blend of performance and drivability.

The disc design can also vary. Common designs include puck-style (also known as sprung hub disc) which have segmented friction material and offer high clamping force but tend to be less forgiving. A sprung hub disc is commonly included, as it helps to dampen vibrations and reduce noise.

3. Flywheel

The flywheel is where the clutch disc mates. Stage 3 clutch kits often recommend, or sometimes require, an aftermarket flywheel. These flywheels can be made of lighter materials (e.g., aluminum) to reduce rotational inertia, improving engine response. However, a lighter flywheel can also make the engine more prone to stalling and can increase noise and vibration. Some kits use a chromoly steel flywheel for increased strength and durability. A new flywheel is often recommended because the old flywheel may be worn or have hot spots that will negatively impact the performance and longevity of the new clutch.

4. Throw-Out Bearing (Release Bearing)

The throw-out bearing, also known as the release bearing, is responsible for disengaging the clutch. While it might seem like a minor component, a failing throw-out bearing can cause significant problems. Stage 3 clutch kits often include an upgraded throw-out bearing to handle the increased clamping force of the pressure plate.

5. Pilot Bearing/Bushing

The pilot bearing or bushing supports the input shaft of the transmission. It's a small but crucial component. Replacing it during a clutch job is highly recommended to prevent future issues.

How a Stage 3 Clutch Works

The basic principle is the same as any clutch, but the components are engineered to handle more power. When the clutch pedal is depressed, the throw-out bearing pushes against the pressure plate fingers, releasing the clamping force on the clutch disc. This disengages the engine from the transmission, allowing you to shift gears. When the pedal is released, the pressure plate clamps the clutch disc against the flywheel, transmitting engine power to the transmission. The higher clamping force of a Stage 3 clutch ensures that this connection remains solid even under high torque loads, preventing slippage.

The upgraded materials of the clutch disc are designed to withstand the higher temperatures generated by increased friction. For example, ceramic materials can handle significantly more heat than organic materials without losing their friction coefficient.

Real-World Use and Troubleshooting Tips

While a Stage 3 clutch offers superior performance, it also comes with some considerations for daily driving:

- Increased Pedal Effort: Expect a stiffer clutch pedal, which can be tiring in stop-and-go traffic.

- Chatter: Aggressive friction materials like ceramic can cause chatter, especially during engagement at low speeds. This is essentially the disc grabbing and releasing rapidly.

- Shorter Lifespan: Due to the aggressive materials and higher clamping force, Stage 3 clutches may have a shorter lifespan than stock clutches, especially if abused.

- Noise: Some Stage 3 clutches can be noisier than stock clutches, particularly during engagement and disengagement. This can be due to the design of the disc or the lighter flywheel.

Troubleshooting:

- Slipping: If the clutch is slipping (engine RPM increases without a corresponding increase in vehicle speed), it could be due to excessive wear, contamination (oil or grease), or insufficient clamping force.

- Chatter: If the clutch chatters excessively, it could be due to hot spots on the flywheel, worn friction material, or improper installation.

- Difficulty Shifting: Difficulty shifting can be caused by a dragging clutch (not fully disengaging), a worn throw-out bearing, or problems with the hydraulic system.

Safety Considerations

Working on a clutch system involves several safety risks:

- Spring Tension: The pressure plate stores a significant amount of spring tension. Improper removal or installation can result in serious injury. Always use the correct tools (clutch alignment tool and possibly a clutch alignment compressor) and follow the manufacturer's instructions carefully.

- Heavy Components: The transmission and flywheel are heavy components. Use proper lifting equipment and techniques to prevent injury.

- Dust: Clutch dust can contain asbestos (especially in older vehicles). Wear a respirator to avoid inhaling dust.

- Hydraulic Fluid: Brake fluid used in hydraulic clutch systems is corrosive. Avoid contact with skin and eyes.

Always disconnect the battery before working on the clutch system to prevent accidental electrical shock.

Conclusion

A Stage 3 clutch represents a significant upgrade in performance capability, but it's not without its trade-offs. By understanding the components, operation, and potential issues, you can make an informed decision about whether a Stage 3 clutch is right for your needs. Remember to prioritize safety and follow the manufacturer's instructions carefully during installation and maintenance.