What Is A Transmission In A Car

Welcome, fellow gearheads! Today, we're diving deep into the heart of your car's drivetrain: the transmission. Understanding your transmission is crucial, whether you're planning a simple fluid change, diagnosing a mysterious clunk, or dreaming of a high-performance rebuild. This isn’t just about knowing names; it's about grasping the core function of this vital component. This article aims to equip you with the knowledge to confidently approach transmission-related tasks, diagnose issues, and understand the jargon thrown around in repair shops.

Why Understanding Your Transmission Matters

Having a good grasp of transmission operation isn't just about impressing your friends at car meets. It's about:

- Saving Money: Being able to diagnose basic transmission problems can save you from unnecessary repairs.

- Performing Maintenance: Properly maintaining your transmission, like changing the fluid and filter, extends its lifespan.

- Understanding Modifications: If you're planning performance upgrades, understanding how the transmission will handle the increased power is critical.

- Troubleshooting: Identifying the source of a driving issue accurately, rather than guessing and replacing parts randomly.

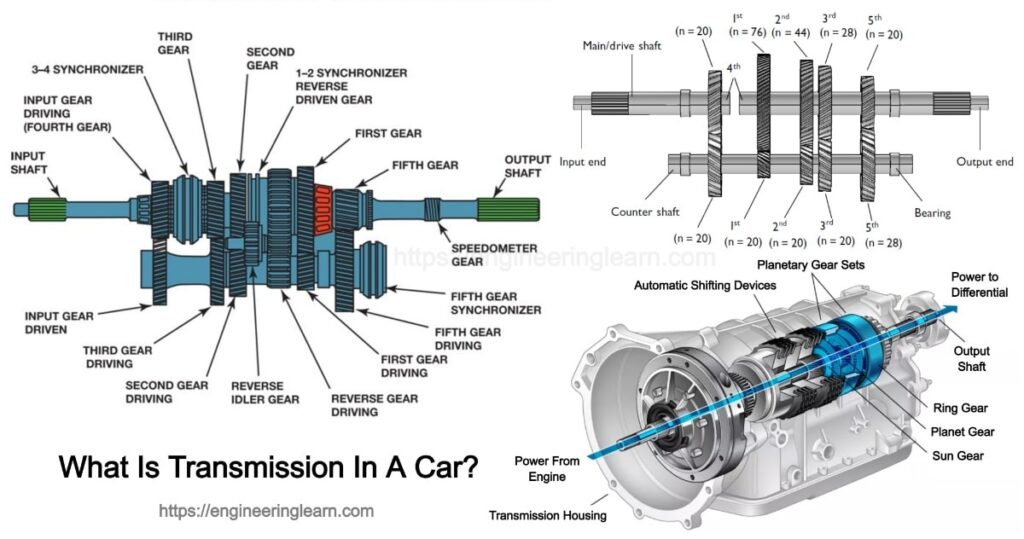

We’ll be referencing diagrams similar to what professional technicians use. We even have a typical automatic transmission diagram available for you to download at the end of the article. This type of diagram provides a visual roadmap of the transmission's components, making understanding its operation much easier.

Key Specs and Main Parts

Let's break down the core components of a typical automatic transmission (though the principles apply broadly to manual transmissions as well):

Key Specs:

- Gear Ratios: These determine the relationship between engine speed (RPM) and wheel speed. Lower gears provide more torque for acceleration, while higher gears offer better fuel economy at cruising speeds. For example, a 3.00:1 gear ratio means the engine turns three times for every one rotation of the output shaft.

- Torque Capacity: This is the maximum amount of torque the transmission can handle without failing. Overpowering a transmission can lead to catastrophic damage.

- Number of Gears: Modern transmissions have anywhere from 4 to 10 gears. More gears generally improve fuel economy and performance.

- Fluid Type: Using the correct Automatic Transmission Fluid (ATF) is absolutely essential. Using the wrong fluid can cause slipping, overheating, and premature wear.

Main Parts (Automatic Transmission):

- Torque Converter: This fluid coupling connects the engine to the transmission. It allows the engine to continue running even when the wheels are stopped, like at a stoplight. It also multiplies torque under heavy acceleration.

- Planetary Gear Sets: These are the heart of the transmission. They consist of sun gears, ring gears, planet gears, and carriers, which are arranged to provide different gear ratios.

- Clutches and Bands: These engage and disengage to lock different parts of the planetary gear sets, creating different gear ratios. Clutches are multi-plate friction devices, while bands are steel straps lined with friction material that clamp around rotating drums.

- Valve Body: This is the "brain" of the automatic transmission. It's a complex network of valves, channels, and solenoids that control the flow of hydraulic fluid to the clutches and bands, determining when to shift gears.

- Transmission Control Module (TCM): This electronic control unit (ECU) receives signals from various sensors (engine speed, throttle position, vehicle speed) and controls the solenoids in the valve body to achieve optimal shifting.

- Oil Pump: The pump circulates the ATF through the transmission, providing hydraulic pressure for the clutches, bands, and torque converter.

- Filter: The filter removes contaminants from the ATF, keeping the system clean.

Manual transmissions have similar, but different components. They use a clutch to disconnect the engine. Instead of a valve body and TCM, the driver chooses the gear using a shift lever which moves forks inside the transmission housing to engage different gear combinations.

Understanding Transmission Diagrams

Transmission diagrams can seem daunting at first, but they’re actually quite logical. Most use a standardized set of symbols and conventions:

- Lines: Lines represent hydraulic fluid passages. Thicker lines typically indicate main supply lines, while thinner lines represent control lines.

- Colors: Colors often denote pressure levels. For example, red might represent high pressure, while blue represents low pressure.

- Circles: Circles can represent gears, pumps, or pressure accumulators.

- Squares/Rectangles: These usually represent valves, solenoids, or other control components.

- Arrows: Arrows indicate the direction of fluid flow.

Pay close attention to the legend or key provided with the diagram. This will tell you exactly what each symbol and color represents. Learning to interpret these diagrams will give you a huge leg up when diagnosing complex problems.

How It Works: A Simplified View

The engine's power is transferred to the transmission via the torque converter (automatic) or clutch (manual). The transmission's job is to efficiently transfer this power to the wheels, providing the appropriate amount of torque and speed for different driving conditions.

Here's a simplified explanation of how an automatic transmission works:

- The engine turns the input shaft of the transmission.

- The torque converter multiplies the engine's torque and transmits it to the planetary gear sets.

- The TCM analyzes sensor data and determines the optimal gear.

- The TCM activates solenoids in the valve body.

- The solenoids control the flow of hydraulic fluid to the appropriate clutches and bands.

- The clutches and bands engage, locking different parts of the planetary gear sets and creating the desired gear ratio.

- The output shaft of the transmission spins at a speed determined by the selected gear ratio.

- The output shaft transmits power to the driveshaft, which then transmits power to the wheels.

Real-World Use: Basic Troubleshooting

Here are some common transmission problems and potential causes:

- Slipping: The engine revs high but the car doesn't accelerate properly. This could be caused by worn clutches, low fluid level, or incorrect fluid type.

- Harsh Shifting: Shifts are jerky or abrupt. This could be due to a faulty solenoid, a problem with the valve body, or incorrect fluid level.

- Delayed Engagement: A delay between shifting into gear and the car moving. This could be caused by low fluid pressure, worn seals, or a failing torque converter.

- Noisy Operation: Whining, buzzing, or clunking sounds coming from the transmission. These could indicate worn bearings, damaged gears, or low fluid level.

- Fluid Leaks: Obvious signs of fluid leaking from the transmission. This could be due to damaged seals, a cracked housing, or a loose fitting.

Before jumping into a repair, always check the basics:

- Fluid Level: Low fluid is a common culprit for many transmission problems. Check the dipstick (if equipped) or consult your owner's manual for the correct procedure.

- Fluid Condition: The fluid should be bright red and translucent. Dark, burnt-smelling fluid indicates a problem.

- Error Codes: Use an OBD-II scanner to check for transmission-related error codes. These codes can provide valuable clues to the underlying problem.

Safety Considerations

Working on transmissions involves potential hazards. Here are some key safety precautions:

- High Pressure: The hydraulic system within the transmission operates at high pressure. Depressurize the system before disconnecting any lines.

- Hot Fluid: ATF can be extremely hot. Allow the transmission to cool down completely before draining the fluid.

- Heavy Components: Transmissions are heavy and awkward to handle. Use a transmission jack or other suitable lifting equipment to prevent injuries.

- Proper Support: Always support the vehicle securely on jack stands before working underneath it.

- Wear Safety Glasses: Protect your eyes from flying debris and fluids.

The valve body is a particularly sensitive area. Dirt and debris can easily clog the small passages, causing malfunctions. Always work in a clean environment and use lint-free cloths when handling valve body components.

We hope this comprehensive overview has helped you better understand the inner workings of your car's transmission. Remember to always consult your vehicle's service manual for specific information and procedures. Now, as promised, you can download a detailed automatic transmission diagram here: [Link to Downloadable Diagram - Placeholder]. Use this diagram in conjunction with this article to deepen your understanding and tackle your next transmission-related project with confidence! Good luck, and happy wrenching!