What Is A Transmission On A Car

Alright folks, let's dive into the heart of your car's drivetrain: the transmission. This isn’t just a collection of gears; it’s the unsung hero translating engine power into usable motion. Understanding the transmission, whether it's an automatic or a manual, is crucial for everything from basic maintenance to more advanced modifications. We'll break down the essential components, explain how it works, and provide practical tips for troubleshooting. Consider this your detailed guide to demystifying your car's gearbox.

Purpose and Importance

Why bother understanding your transmission? Several reasons. First, if you’re tackling repairs yourself, knowing the anatomy and function of the transmission is vital. It allows you to diagnose problems accurately and perform repairs efficiently. Second, if you're considering performance upgrades, understanding how the transmission interacts with the engine and driveline is crucial for selecting the right modifications. Finally, even for general car ownership, knowing the basics of transmission operation can help you identify early warning signs of problems, potentially saving you from costly repairs down the road. This knowledge can also significantly improve your ability to communicate with professional mechanics and understand their recommendations.

Key Specs and Main Parts

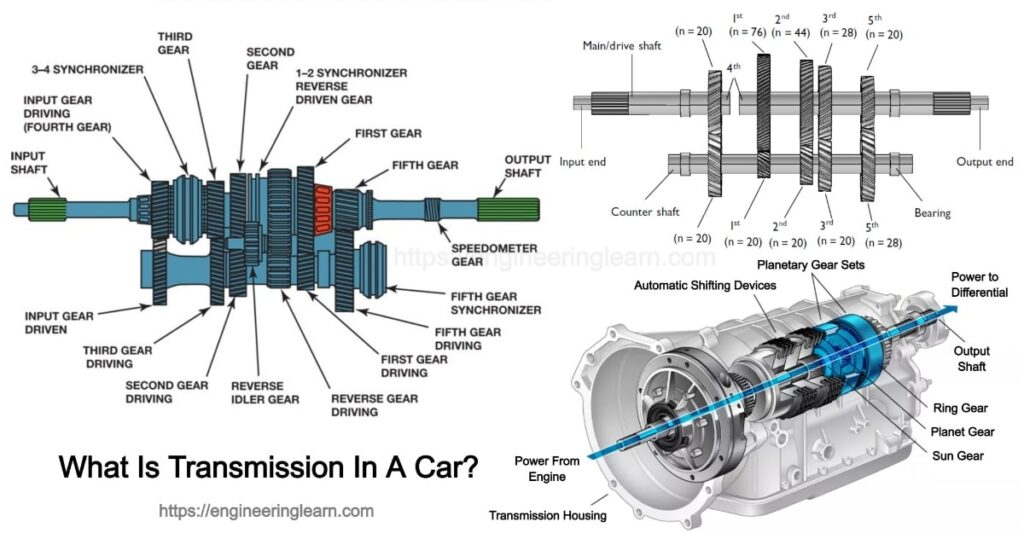

Let's start with the major players inside the transmission. This section covers the general components found in both manual and automatic transmissions. We'll highlight specific differences later.

Common Components:

- Input Shaft: The input shaft is directly connected to the engine (either via a clutch in a manual transmission or a torque converter in an automatic). It's the entry point for engine power.

- Output Shaft: The output shaft delivers power from the transmission to the driveshaft or axles, ultimately turning the wheels.

- Gears: A series of gears of varying sizes, arranged in different combinations, provide different gear ratios, allowing the engine to operate efficiently at various speeds.

- Shafts: Transmission shafts are used to support the gears and transmit torque between them.

- Bearings: Bearings minimize friction and allow the gears and shafts to spin freely.

- Synchronizers (Manual Transmissions): These components synchronize the speeds of the gears before they engage, preventing grinding and ensuring smooth shifts.

- Clutch (Manual Transmissions): The clutch disengages the engine from the transmission, allowing the driver to change gears without stalling the engine.

- Torque Converter (Automatic Transmissions): The torque converter is a fluid coupling that transmits power from the engine to the transmission. It also multiplies torque, providing improved acceleration.

- Valve Body (Automatic Transmissions): The valve body is the brain of an automatic transmission. It contains a series of valves that control the flow of hydraulic fluid, which engages different gears.

- Planetary Gear Sets (Automatic Transmissions): Planetary gear sets are used in automatic transmissions to achieve different gear ratios.

- Transmission Fluid: All transmissions require transmission fluid for lubrication, cooling, and hydraulic pressure (in automatic transmissions).

- Case: The case houses and protects all the internal components of the transmission.

Key Specs to Consider:

- Gear Ratios: The ratio of the number of teeth on the input gear to the number of teeth on the output gear. Affects acceleration and fuel economy. Lower gears (higher numerical ratio) provide more torque for acceleration, while higher gears (lower numerical ratio) provide better fuel economy at cruising speed.

- Transmission Type: Manual (MT), Automatic (AT), Continuously Variable Transmission (CVT), Dual-Clutch Transmission (DCT). Each has different operating principles and performance characteristics.

- Number of Gears: More gears can improve fuel economy and acceleration by allowing the engine to operate closer to its optimal RPM range.

- Torque Capacity: The maximum amount of torque the transmission can handle without damage. Crucial for high-performance applications.

How It Works

The fundamental principle of a transmission is to provide different gear ratios to match engine output to vehicle speed and load. At low speeds and during acceleration, a lower gear ratio (e.g., first gear) is used to multiply engine torque, providing more power to the wheels. At higher speeds, a higher gear ratio (e.g., fifth or sixth gear) is used to improve fuel economy and reduce engine wear. Let's look at manual and automatic transmissions separately.

Manual Transmissions:

In a manual transmission, the driver selects the desired gear by using the gearshift lever. When the driver presses the clutch pedal, the engine is disengaged from the transmission. The driver then moves the gearshift lever to select the desired gear. This action engages synchronizers, which match the speed of the selected gear to the output shaft. When the driver releases the clutch pedal, the engine is re-engaged, and power is transmitted to the wheels through the selected gear ratio. Shifting gears involves interrupting the power flow, selecting a new gear ratio, and re-engaging the power flow smoothly.

Automatic Transmissions:

Automatic transmissions use a torque converter to transmit power from the engine to the transmission. The torque converter consists of three main components: an impeller (connected to the engine), a turbine (connected to the transmission), and a stator (which redirects fluid flow to multiply torque). The valve body controls the flow of hydraulic fluid to engage different clutches and bands, which select different gear ratios. The valve body uses a combination of hydraulic pressure and electronic signals (from sensors and the car's computer) to determine when to shift gears. Planetary gear sets, rather than individual gears on shafts, are how the gear ratios are changed in automatic transmissions. These gear sets consist of a sun gear, planet gears, a ring gear, and a carrier, and by locking different combinations of these components together, different gear ratios are achieved automatically.

Real-World Use – Basic Troubleshooting Tips

Here are some common transmission problems and how to identify them:

- Slipping Gears: The engine revs up without a corresponding increase in vehicle speed. This can be caused by worn clutches (in both automatic and manual transmissions), low transmission fluid, or a faulty valve body (in automatic transmissions).

- Rough Shifting: Jerky or clunky gear changes. This can be caused by worn synchronizers (in manual transmissions), low transmission fluid, a faulty valve body (in automatic transmissions), or worn transmission mounts.

- Delayed Engagement: A delay between shifting into gear and the vehicle moving. This is most common in automatic transmissions and can be caused by low transmission fluid, a faulty valve body, or worn clutches.

- Unusual Noises: Grinding, whining, or clunking noises coming from the transmission. These can be caused by worn gears, bearings, or other internal components.

- Fluid Leaks: Transmission fluid leaks can cause low fluid levels, leading to poor performance and potential damage. Check for leaks around the transmission pan, seals, and lines.

Quick Checks:

- Fluid Level: Check the transmission fluid level regularly using the dipstick (if equipped). Follow the manufacturer's instructions for the proper procedure.

- Fluid Condition: Examine the transmission fluid for color and smell. Healthy fluid is typically red or pink and has a slightly sweet smell. Dark, burnt-smelling fluid indicates a problem.

- Listen for Noises: Pay attention to any unusual noises coming from the transmission while driving.

Safety – Highlight Risky Components

Working on a transmission can be dangerous if proper precautions are not taken.

- High Pressures: Automatic transmissions operate at high hydraulic pressures. Always relieve pressure before disconnecting any lines or components.

- Hot Fluids: Transmission fluid can be extremely hot. Allow the transmission to cool down before working on it.

- Heavy Components: Transmissions are heavy and can be difficult to handle. Use proper lifting equipment and techniques to avoid injury.

- Sharp Edges: Transmission components can have sharp edges. Wear gloves to protect your hands.

- Proper Support: When the transmission is removed from the car, make sure to properly support the car on jack stands. Never work underneath a car supported only by a jack.

Specifically, avoid tampering with the torque converter without proper training and equipment. It contains high pressures and can be very dangerous if mishandled. Always disconnect the battery before working on any electrical components related to the transmission.

With a solid understanding of your transmission, you can confidently diagnose issues, tackle basic maintenance, and even consider performance modifications. Remember to prioritize safety and consult professional resources when dealing with complex repairs.

We have a detailed transmission diagram available for download. This visual aid can further enhance your understanding and assist in troubleshooting. Contact us to receive your copy.