What Is A Zero Emissions Vehicle

So, you're diving into the world of zero-emission vehicles (ZEVs)? Smart move! Whether you're considering an EV conversion, learning more about the tech, or just trying to understand what all the hype is about, understanding ZEVs under the hood is becoming essential for any serious car enthusiast. This article will break down the key components, how they work, and some of the basic troubleshooting you might encounter. Think of it as your ZEV 101 guide for the DIY mechanic.

What *Exactly* is a Zero-Emission Vehicle?

Let's start with the basics. A Zero-Emission Vehicle, or ZEV, is any vehicle that emits absolutely no tailpipe pollutants from its onboard power source. Crucially, it has to be zero emissions at the point of operation. That's the key difference from vehicles that simply reduce emissions, like hybrids.

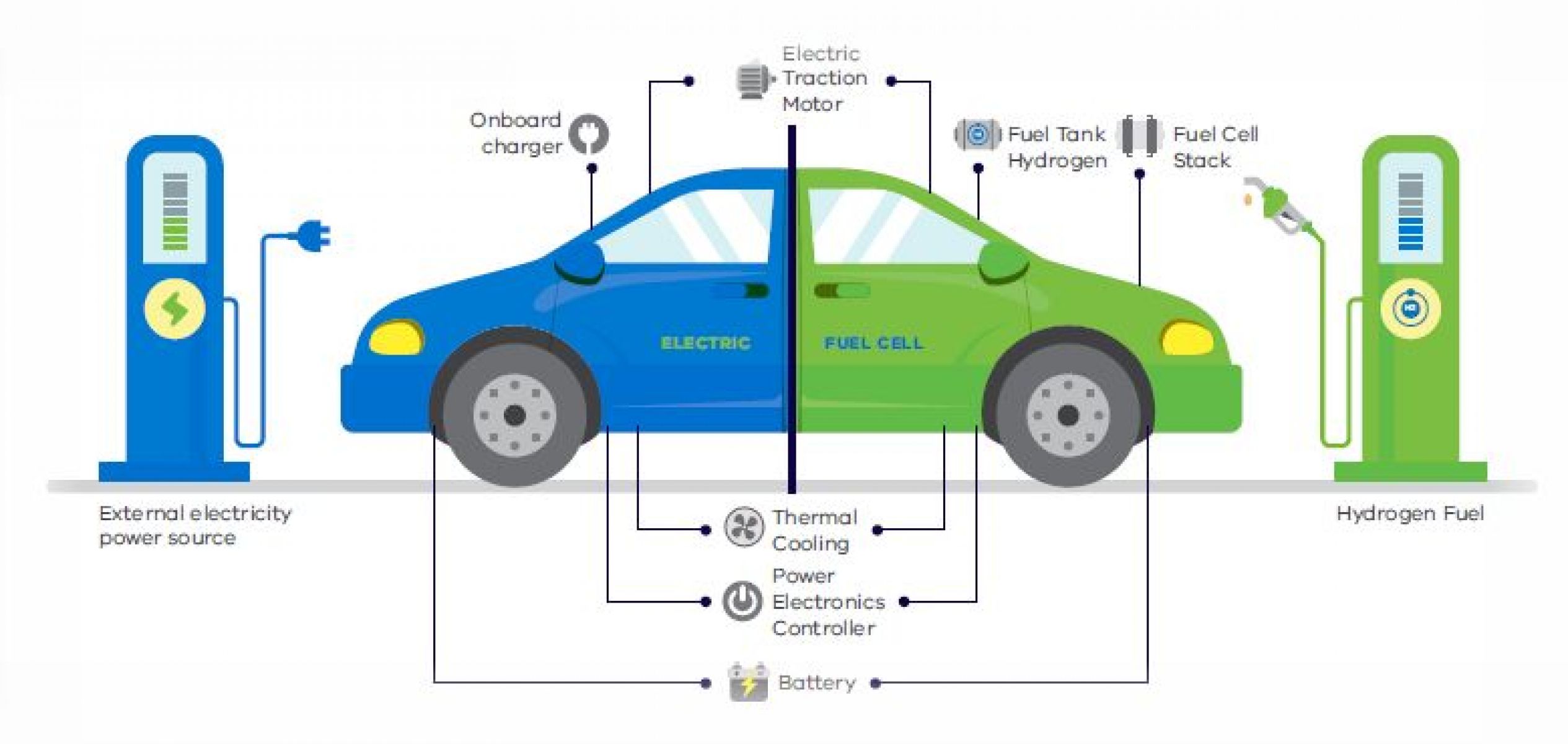

While battery electric vehicles (BEVs) are the most common type of ZEV today, hydrogen fuel cell electric vehicles (FCEVs) also qualify. The "emission" comes from burning gasoline/diesel, which are the sources of carbon pollution, like carbon dioxide, as well as toxic pollutants, like particulate matter and NOx (nitrogen oxides).

Purpose: Understanding ZEV technology is increasingly vital for maintenance, repairs, and modifications. As the automotive industry shifts towards electrification, having a grasp of the core systems will allow you to diagnose problems, perform basic repairs, and potentially even modify your own vehicle (safely, of course!). Plus, knowledge is power when it comes to choosing the right ZEV for your needs.

Key Specs and Main Parts of a BEV (Battery Electric Vehicle)

For the rest of this discussion, we will focus on the Battery Electric Vehicle (BEV) as it is the most ubiquitous and mature ZEV technology today.

Let's break down the main components of a typical BEV drivetrain:

- High-Voltage Battery Pack: This is the energy storage powerhouse of the vehicle. It typically consists of hundreds or thousands of individual lithium-ion battery cells connected in series and parallel. The pack is carefully managed to maintain a consistent charge and temperature across all cells. Key specs: Voltage (typically 200-800V), Capacity (measured in kWh - kilowatt-hours), Discharge Rate (C-rate - how quickly the battery can be discharged)

- Electric Motor (Traction Motor): This is the device that actually turns the wheels. Most BEVs use AC (Alternating Current) motors, either induction or synchronous. Key specs: Power (kW or HP), Torque (Nm or lb-ft), RPM (Revolutions Per Minute), Efficiency (percentage)

- Inverter: This device converts the DC (Direct Current) power from the battery pack into AC power for the electric motor. It also controls the speed and torque of the motor.

- Onboard Charger (OBC): This converts AC power from the grid (or a charging station) into DC power to charge the battery pack. Key specs: Charging power (kW), Voltage (input and output), Charging speed (miles added per hour)

- DC-DC Converter: This converts the high-voltage DC power from the battery pack to lower-voltage DC power (typically 12V) to run the vehicle's auxiliary systems (lights, infotainment, etc.).

- Thermal Management System: This system regulates the temperature of the battery pack, electric motor, and other components. It's critical for maintaining battery life, performance, and safety.

- Transmission (Gearbox): Many BEVs have a single-speed gearbox (reduction gear) to optimize the motor's torque output. Some have more complex multi-speed transmissions, but these are less common.

- Braking System: Includes traditional friction brakes, but also features regenerative braking. This system uses the electric motor as a generator during deceleration to recapture energy and send it back to the battery.

Symbols and Schematics

Understanding electrical schematics is crucial for working on ZEVs. Here's a quick guide to some common symbols:

- Solid Lines: Indicate high-voltage DC power lines. These carry significant current and should only be handled by trained professionals with appropriate safety gear.

- Dashed Lines: Indicate low-voltage DC control signals (typically 12V).

- Ground Symbol: Indicates the electrical ground connection.

- Battery Symbol: Represents the high-voltage battery pack.

- Motor Symbol: Represents the electric motor.

- Inverter Symbol: Often depicted as a rectangle with input and output connections.

- Charger Symbol: Similar to the inverter symbol.

- Thermal Management System Components: Pumps, valves, and sensors are represented by their standard symbols.

How It Works (Simplified Overview)

The process is relatively straightforward:

- The high-voltage battery pack stores energy.

- When the driver presses the accelerator pedal, the vehicle control unit (VCU) signals the inverter to convert DC power from the battery into AC power.

- The inverter controls the frequency and voltage of the AC power to regulate the speed and torque of the electric motor.

- The electric motor turns the wheels via the transmission (if present).

- During deceleration, the regenerative braking system captures energy and sends it back to the battery.

- When charging, the onboard charger converts AC power from the grid into DC power and stores it in the battery pack.

Real-World Use - Basic Troubleshooting Tips

While you shouldn't attempt to fix high-voltage components yourself without proper training, here are a few basic troubleshooting steps you can take:

- Check the charging cable and charging port: Make sure the cable is properly connected and that there are no signs of damage. Clean the charging port if necessary.

- Check the 12V battery: A weak or dead 12V battery can cause various issues, even in a BEV. Check its voltage and consider replacing it if it's old.

- Check for error codes: Many BEVs have onboard diagnostic systems that can display error codes. Use an OBD-II scanner to read these codes and research their meaning.

- Check the thermal management system: Listen for unusual noises from the cooling system and check the coolant level.

Important Note: Many EV problems require specialized diagnostic tools and expertise. If you're unsure about anything, it's best to consult a qualified technician.

Safety - High-Voltage Hazards!

This cannot be stressed enough: Working with high-voltage systems is extremely dangerous and can be fatal. Do not attempt to disassemble or repair the high-voltage battery pack, inverter, or motor unless you have proper training and safety equipment. These components can carry hundreds of volts and can deliver a lethal shock.

Always follow these safety precautions:

- Wear insulated gloves and safety glasses.

- Disconnect the high-voltage battery pack before working on any electrical components. (This requires specific procedures and tools – consult the service manual for your vehicle).

- Use a high-voltage meter to verify that the system is de-energized.

- Never work alone.

- If you're unsure about anything, stop and consult a qualified technician.

Conclusion

ZEVs, particularly BEVs, are revolutionizing the automotive industry. Understanding their core components and how they work is becoming increasingly important for car enthusiasts and mechanics alike. While working on high-voltage systems requires specialized training and safety precautions, having a basic understanding of ZEV technology will help you diagnose problems, perform basic maintenance, and appreciate the advancements in electric vehicle technology.

We have a detailed schematic available for download. It includes detailed wiring diagrams, sensor locations, and component specifications. It is in PDF format and will be a valuable tool for your learning and troubleshooting endeavors. Good luck, and stay safe!