What Is All Wheel Drive Cars

Alright, let's dive deep into the world of all-wheel drive (AWD) systems. As an experienced DIYer, you probably understand the basics, but we're going to dissect the technology and get into the nitty-gritty. Whether you're planning a repair, considering an AWD conversion, or just want a more thorough understanding of how your vehicle works, this knowledge is invaluable.

Understanding All-Wheel Drive: Purpose and Basics

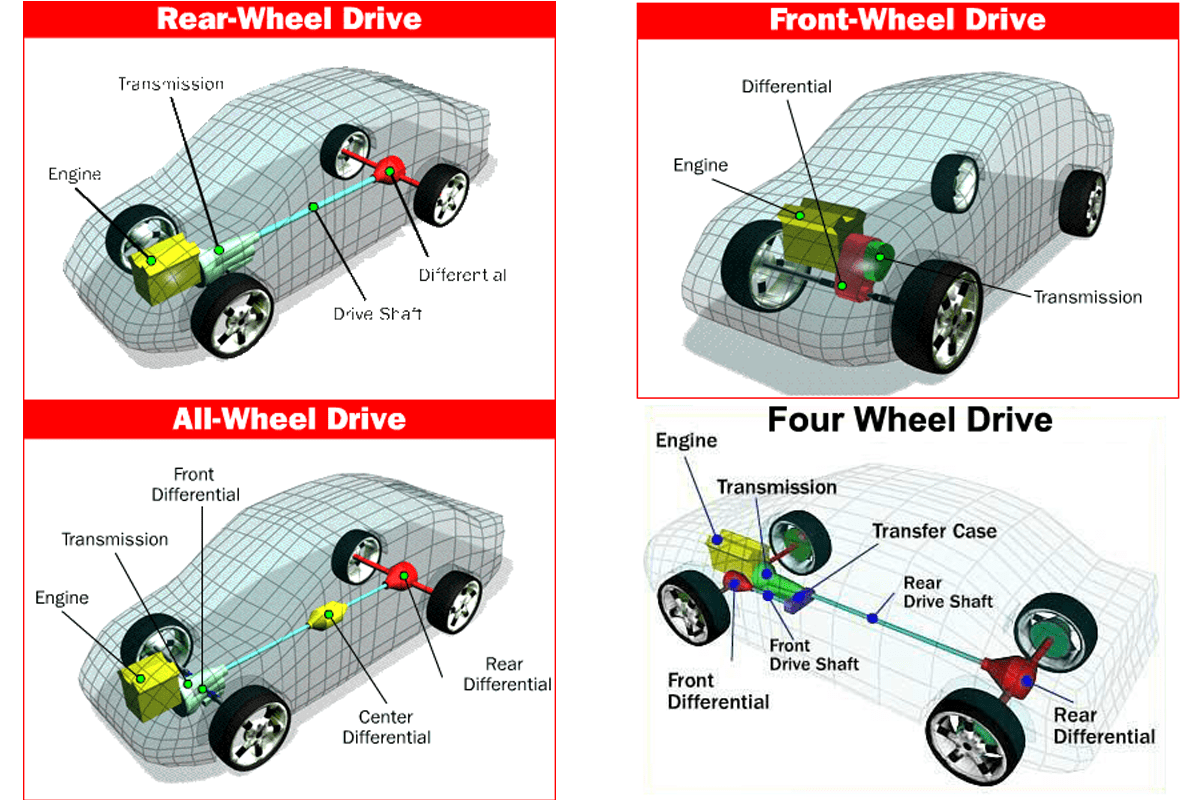

The purpose of an AWD system is simple: to improve traction. By sending power to all four wheels instead of just two (as in front-wheel drive or rear-wheel drive), an AWD vehicle can maintain better grip in slippery conditions like snow, ice, mud, or even loose gravel. This translates to improved acceleration, handling, and stability, especially in challenging driving scenarios. This becomes vital when considering repairs, as different AWD systems require different levels of care and understanding of their components.

We have a detailed diagram of a typical AWD system available for download, showing the layout and relationships between the major components. This diagram is your go-to resource when understanding how your AWD system is set up. Having this to hand will help guide you when trouble shooting, or replacing parts. We will tell you how to access this file at the end.

Key Specs and Main Parts of an AWD System

AWD systems aren't monolithic. There are various types, each with its own nuances. However, certain core components are common across most designs:

- Engine: The source of power, just like in any other vehicle.

- Transmission: Transfers power from the engine and allows for gear changes.

- Transfer Case (or Power Transfer Unit – PTU): This is a critical component unique to AWD vehicles. It splits the engine's power between the front and rear axles. The specific split ratio varies depending on the system design. Some PTUs have viscous couplings or clutches for variable torque distribution.

- Front Differential: Allows the front wheels to rotate at different speeds, which is necessary when cornering.

- Rear Differential: Same as the front differential, but for the rear wheels.

- Drive Shaft (Propeller Shaft): Connects the transfer case to the rear differential.

- Axle Shafts: Connect the differentials to the wheels, delivering the final drive power.

- Wheel Speed Sensors: These sensors (often integrated into the ABS system) monitor the rotational speed of each wheel. This data is used by the AWD control system to detect wheel slip and adjust torque distribution accordingly.

- AWD Control Module (ECU): This electronic control unit monitors various sensors and controls the operation of the AWD system, including the transfer case and any electronically controlled clutches or differentials.

Key Specs: These will vary drastically between car, make and model, but here are some terms to be aware of.

- Torque Split:The most crucial spec is the front-to-rear torque split. Some systems have a fixed split (e.g., 50/50), while others are variable and can adjust the split based on driving conditions.

- Response Time: How quickly the AWD system can react to wheel slip and redistribute torque. Faster response times generally translate to better traction and stability.

- System Type: Is it part-time AWD (engages only when needed) or full-time AWD (always engaged)?

Understanding AWD Symbols and the Downloadable Diagram

The diagram we provide uses standard automotive symbols. Here's a breakdown of what to expect:

- Lines: Solid lines typically represent mechanical connections (e.g., drive shafts), while dashed lines often indicate electrical signals or hydraulic lines.

- Arrows: Indicate the direction of power flow.

- Color Coding: Different colors may be used to differentiate between various systems or components (e.g., hydraulic lines vs. electrical wiring). Consult the diagram's legend for specifics.

- Icons: Specific icons represent components such as differentials, clutches, sensors, and the control module. Again, the legend will define these.

Pay close attention to the layout of the components and how they interact. The diagram will illustrate the flow of power from the engine, through the transmission and transfer case, to the front and rear differentials, and finally to the wheels. Understanding this flow is essential for troubleshooting.

How All-Wheel Drive Systems Work

The basic principle is that the transfer case (or PTU) splits the engine's power between the front and rear axles. How this split is managed depends on the type of AWD system. Here's a brief overview of some common types:

- Part-Time AWD: Typically found in older trucks and SUVs, these systems require the driver to manually engage AWD, usually via a lever or button. They are not designed for on-pavement use, as the fixed torque split can cause driveline binding (wind-up) when cornering on surfaces with high traction.

- Full-Time AWD: These systems are always engaged and automatically distribute torque between the front and rear axles. They use a center differential (or viscous coupling or clutch pack) to allow for differences in wheel speeds when cornering, preventing driveline binding.

- Automatic AWD: These systems operate primarily in two-wheel drive (FWD or RWD) but automatically engage AWD when wheel slip is detected. They typically use electronically controlled clutches to engage the rear axle.

- Torque Vectoring AWD: More advanced systems can not only distribute torque between the front and rear axles but also between the left and right wheels on each axle. This is typically achieved using electronically controlled clutches or differentials and can significantly improve handling and stability.

Modern AWD systems often rely heavily on electronic sensors and control modules. Wheel speed sensors detect wheel slip, and the AWD control module responds by adjusting the torque split to maintain optimal traction. This happens in milliseconds, making the system highly responsive to changing driving conditions.

Real-World Use and Basic Troubleshooting Tips

Here are some common issues you might encounter with an AWD system:

- Noisy Operation: Grinding, whining, or clunking noises can indicate worn bearings, damaged gears, or low fluid levels in the transfer case or differentials.

- Vibrations: Vibrations, especially at higher speeds, can be caused by a worn or unbalanced drive shaft, damaged CV joints (constant velocity joints), or loose mounting hardware.

- AWD System Warning Lights: These lights indicate a problem with the AWD system. Common causes include faulty wheel speed sensors, a malfunctioning AWD control module, or a problem with the transfer case or differentials. Have the codes read!

- Lack of Traction: If you're experiencing poor traction in slippery conditions despite having AWD, check the condition of your tires. Worn tires can significantly reduce traction.

Basic Troubleshooting Steps:

- Check Fluid Levels: Regularly check the fluid levels in the transfer case and differentials. Use the correct type of fluid as specified by the vehicle manufacturer.

- Inspect for Leaks: Look for signs of leaks around the transfer case, differentials, and drive shaft. Address any leaks promptly to prevent further damage.

- Check CV Joints: Inspect the CV joint boots for cracks or tears. Damaged boots can allow dirt and water to enter the joint, leading to premature wear and failure.

- Listen for Unusual Noises: Pay attention to any unusual noises coming from the AWD system. These noises can often provide clues about the source of the problem.

Safety Considerations

Working on an AWD system can be risky if you're not careful. Here are some important safety precautions:

- Disconnect the Battery: Always disconnect the negative battery cable before working on any electrical components.

- Support the Vehicle Properly: Use jack stands to support the vehicle when working underneath it. Never rely solely on a jack.

- Use the Right Tools: Use the correct tools for the job. Using the wrong tools can damage components and increase the risk of injury.

- Be Careful with Fluids: Some AWD system fluids can be hazardous. Wear gloves and eye protection when handling them. Dispose of used fluids properly.

- High-Pressure Components: If your AWD system has hydraulic components (e.g., for torque vectoring), be aware of the high pressures involved. Do not attempt to disassemble these components without the proper training and equipment.

Specific Risky Components:

- CV Joints: Be careful when disassembling CV joints, as they can contain spring-loaded components that can cause injury if released unexpectedly.

- Differentials: Differentials contain gears that can be sharp. Wear gloves to protect your hands.

- Electronic Components: Be careful when working with electronic components. Follow the manufacturer's instructions carefully to avoid damaging the components.

Warning: When disassembling drive shafts, be sure to mark the orientation of the yokes before separating them. Reassembling them in the wrong orientation can cause vibrations. Torque all bolts to the manufacturer's specifications.

Hopefully, this explanation has provided you with a more detailed understanding of AWD systems. Remember to consult your vehicle's service manual for specific information about your particular AWD system.

To download the detailed AWD system diagram, please Click Here (replace "#" with the actual link to your file). This diagram will be a valuable asset as you continue to learn and work on AWD systems.