What Is All Wheel Drive In A Car

Alright, let's dive deep into the fascinating world of All-Wheel Drive (AWD) systems. As an experienced DIYer, understanding your car's drivetrain is crucial, whether you're planning upgrades, diagnosing issues, or just want to truly understand what's happening under the hood. This article aims to provide a clear, technical breakdown of AWD, making it accessible to even the most seasoned home mechanics.

Purpose of Understanding AWD

Why bother learning about AWD? Plenty of reasons! Firstly, accurate diagnostics. When your AWD system isn't working correctly, understanding the components and how they interact is key to pinpointing the problem, saving you time and money on potentially misdiagnosed repairs. Secondly, it's critical for making informed modification decisions. Thinking of lifting your truck or adding performance parts? Knowing how those changes affect your AWD system is paramount. Finally, pure knowledge. As car enthusiasts, we simply want to know how things work!

Key Specs and Main Parts

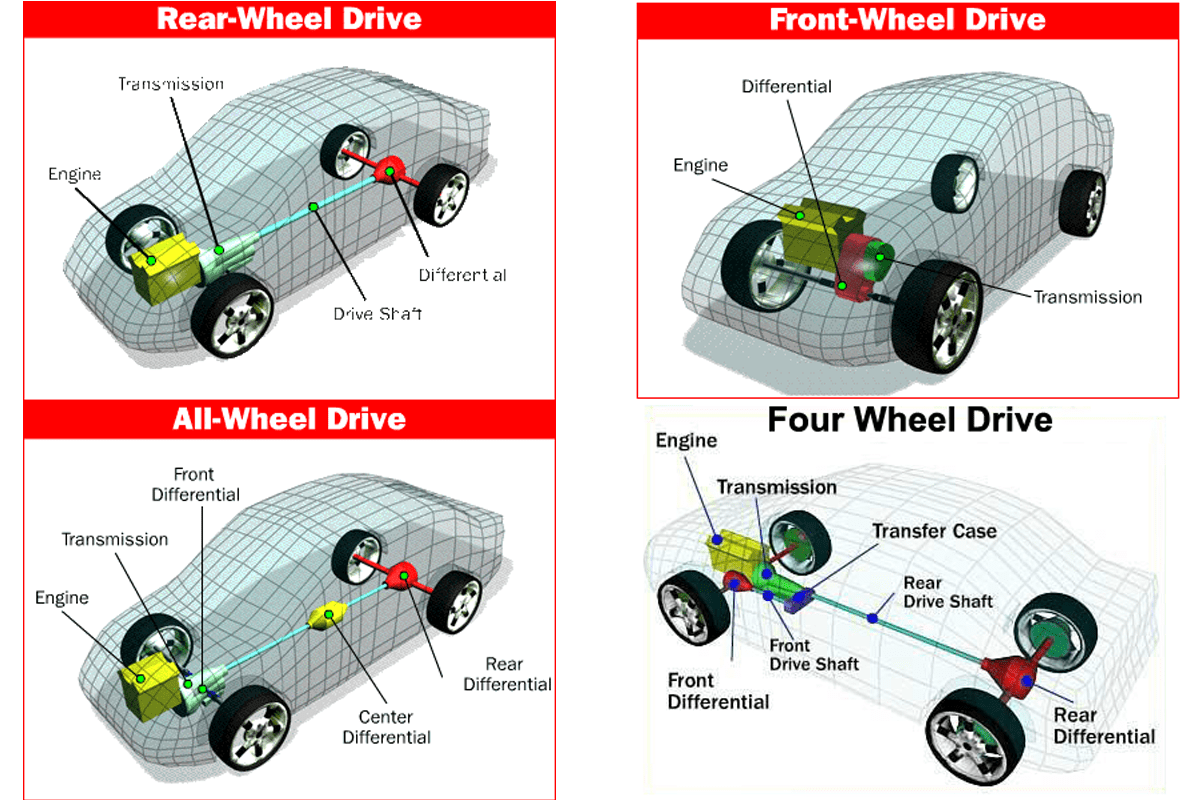

AWD systems come in various flavors, but the fundamental goal is to distribute torque to all four wheels. This provides improved traction and handling, especially in slippery conditions. Here's a breakdown of the key components:

- Engine: The heart of the operation, providing the initial power. We'll assume you know this!

- Transmission: The gearbox that multiplies engine torque and transmits it to the drivetrain. Most modern AWD cars use automatic transmissions.

- Transfer Case (or Power Take-Off Unit - PTU): This is the critical component that splits the engine's power between the front and rear axles. In some systems, it's a separate unit bolted to the transmission; in others, it's integrated within the transmission housing.

- Front Differential: A differential allows each wheel on an axle to rotate at different speeds, which is essential when turning.

- Rear Differential: Same function as the front differential, but on the rear axle.

- Driveshaft(s): Connects the transfer case to the front and rear differentials, transmitting rotational power.

- Axle Shafts (Half Shafts): Connect the differentials to the wheels.

- Clutch Packs/Couplings (in some systems): Used to engage or disengage the rear axle, allowing for on-demand AWD. These are often electronically controlled.

- Sensors and Control Units: Modern AWD systems rely heavily on sensors (wheel speed, throttle position, steering angle, etc.) and electronic control units (ECUs) to intelligently distribute torque.

Understanding AWD System Symbols in Diagrams

AWD diagrams use a standardized set of symbols to represent components and connections. Here's a guide to decoding them:

- Solid Lines: Represent a direct mechanical connection, such as a driveshaft or axle shaft.

- Dashed Lines: Often indicate an electronic connection, such as wiring between sensors and the ECU.

- Gear Symbols: Obviously, represent gears within the transmission, transfer case, or differentials. The number of teeth may be indicated.

- Clutch Symbols: Represent clutch packs or couplings used to engage or disengage axles. These often look like stacked plates.

- Differential Symbols: Typically a circle with a small gear symbol inside.

- Arrow Direction: Indicates the direction of power flow.

- Color Coding: Can vary, but often blue indicates fluid lines (transmission oil, differential oil), red indicates electrical power, and black indicates mechanical components.

How AWD Works: A Deeper Dive

The core principle of AWD is simple: send power to all four wheels to maximize traction. However, the implementation varies widely. Here are a few common AWD system types:

- Full-Time AWD: All four wheels are constantly driven. These systems typically use a center differential (often a viscous coupling or Torsen differential) in the transfer case to allow for speed differences between the front and rear axles. Without a center differential, the drivetrain would bind up on pavement. This is because the front wheels travel a slightly longer distance than the rear wheels during turns.

- Part-Time AWD: Typically found in older trucks and SUVs. These systems lock the front and rear axles together, providing maximum traction but only for low-traction surfaces like dirt, snow, or ice. Using part-time AWD on dry pavement can cause severe drivetrain damage due to drivetrain binding. Part-time AWD vehicles must not be driven on dry pavement in AWD mode.

- On-Demand AWD: The vehicle typically operates in two-wheel drive (usually front-wheel drive) until sensors detect wheel slip. At that point, an electronically controlled clutch pack or coupling engages the rear axle, sending power to the rear wheels. These systems offer a good balance of fuel economy and traction. Haldex systems are a common example.

- Electronic AWD (eAWD): Found in hybrid and electric vehicles. These systems typically have an electric motor dedicated to driving one axle (often the rear), while the internal combustion engine (or another electric motor) drives the other axle. This allows for independent control of each axle, enabling sophisticated torque vectoring and improved handling.

Torque vectoring is a more advanced feature often found in high-performance AWD systems. It uses electronically controlled clutches or differentials to distribute torque not only between the front and rear axles but also between the left and right wheels on each axle. This can significantly improve handling by overdriving the outside wheels in a turn, helping the car rotate. It's basically an electronic limited slip differential system.

Real-World Use: Basic Troubleshooting

Suspect your AWD system is acting up? Here are a few basic troubleshooting steps you can take:

- Check for Warning Lights: Your car's dashboard is your first line of defense. A flashing or solid AWD warning light indicates a problem. Use an OBD-II scanner to retrieve the trouble code(s), which can provide valuable clues.

- Listen for Unusual Noises: Grinding, clunking, or whining sounds coming from the drivetrain can indicate a problem with the transfer case, differentials, or driveshafts.

- Inspect for Leaks: Check for oil leaks around the transfer case, differentials, and axle seals. Low fluid levels can damage these components.

- Perform a Basic Traction Test: Find a safe, slippery surface (like a gravel road or snow-covered area) and try accelerating. Do all four wheels spin? If not, there's likely a problem with the AWD system. Be cautious and avoid excessive wheel spin.

- Check AWD Fuses and Relays: Before tearing into complex components, check the simple stuff. Look in your owner's manual for the location of AWD-related fuses and relays. A blown fuse or faulty relay can disable the AWD system.

Important Note: AWD problems can sometimes mimic other issues, such as tire pressure imbalances or worn suspension components. Make sure to rule out these possibilities before focusing solely on the AWD system.

Safety Considerations

Working on AWD systems can be dangerous if you're not careful. Here are some crucial safety precautions:

- Disconnect the Battery: Before working on any electrical components, disconnect the negative battery cable to prevent accidental shorts.

- Support the Vehicle Properly: Use jack stands to support the vehicle securely before getting underneath. Never rely solely on a jack.

- Be Aware of Rotating Parts: When the engine is running (for diagnostic purposes), be extremely cautious around rotating parts like driveshafts and axle shafts. Keep loose clothing and tools away.

- Use the Correct Tools: AWD components often require specialized tools, such as torque wrenches and bearing presses. Using the wrong tools can damage the components or injure yourself.

- Torque to Spec: Always torque fasteners to the manufacturer's specified torque values. Over-tightening can damage the components, while under-tightening can lead to them loosening.

- Wear Safety Glasses: Protect your eyes from debris.

The transfer case and differentials contain heavy gears and can leak messy, stinky oil. Be prepared to deal with that. The driveshaft, if removed, can be heavy and awkward to handle.

Working with the electronics of modern AWD systems requires a good understanding of electrical troubleshooting and the use of diagnostic tools. If you're not comfortable with electrical work, it's best to leave it to a professional.

We hope this detailed breakdown provides a solid foundation for understanding AWD systems. Remember, proper diagnostics, careful work, and adherence to safety precautions are essential for successful DIY repairs and modifications. Don't hesitate to consult a professional mechanic if you're unsure about any aspect of the work.

We have a detailed AWD system diagram available for download. This diagram provides a visual representation of the components and their connections, making it easier to understand the system's operation. This is a great resource for anyone planning repairs or modifications to their AWD system. You can download the diagram here.