What Is All Wheel Drive Mean

Alright, let's dive deep into the world of All-Wheel Drive (AWD) systems. As a seasoned DIYer, understanding the ins and outs of AWD is crucial, whether you're diagnosing a clunk, planning a modification, or simply want to impress your friends with your automotive knowledge. This article is your comprehensive guide, explaining the intricacies of AWD systems in a way that's both technical and easy to grasp. We'll cover everything from the purpose of understanding AWD to troubleshooting common issues, and even touch upon safety considerations.

Purpose of Understanding AWD Systems

Why bother understanding AWD? It's simple: knowledge is power. Specifically, it empowers you to:

- Diagnose Issues Accurately: No more guessing games when your AWD system acts up. Understanding how it works lets you pinpoint the problem.

- Perform Repairs Confidently: Knowing the components and their functions allows you to tackle repairs yourself, saving money and gaining valuable experience.

- Make Informed Modification Decisions: Thinking about lifting your truck or adding larger tires? Understanding how those changes impact your AWD system is vital.

- Appreciate the Technology: AWD is a marvel of engineering. Understanding it will give you a deeper appreciation for your vehicle.

Key Specs and Main Parts of an AWD System

AWD systems aren't one-size-fits-all. Different manufacturers use different approaches, but some core components are consistent. Let's break them down:

Core Components

- Engine: The heart of the operation, providing the power that eventually reaches the wheels.

- Transmission: Transmits power from the engine to the drivetrain, often with gear ratios to optimize torque and speed.

- Transfer Case: This is where the magic of AWD happens. The transfer case splits the power from the transmission and sends it to both the front and rear axles. It often contains gears, clutches, or viscous couplings to manage the torque distribution. Some systems use a Power Transfer Unit (PTU), which is often smaller and lighter, typically found in lighter-duty AWD applications.

- Front and Rear Differentials: These allow the wheels on each axle to rotate at different speeds, essential for turning. Open differentials are the most common, but limited-slip or locking differentials are also used in some AWD systems for improved traction.

- Driveshafts (Propeller Shafts): Connect the transfer case to the front and rear differentials. They transmit the rotational power.

- Axle Shafts: Connect the differentials to the wheels.

- Wheel Speed Sensors (WSS): Used in conjunction with ABS and traction control systems to detect wheel slip. These sensors often feed information to the AWD system's control unit.

- AWD Control Unit (ECU): Many modern AWD systems are electronically controlled. This unit monitors sensor data and controls the transfer case or clutches to optimize torque distribution based on driving conditions.

Key Specifications

- Torque Split: The percentage of torque sent to the front and rear axles. Common examples are 50/50 (equal distribution) or variable splits that adjust dynamically.

- AWD System Type: Permanent AWD (always engaged), part-time AWD (selectable engagement), or automatic AWD (engages based on conditions).

- Differential Type: Open, limited-slip, or locking. Affects traction performance.

- Clutch Type (If Applicable): Multi-plate wet clutch, viscous coupling, etc. Affects the speed and smoothness of torque transfer.

- Engagement Method: Electronic, mechanical, or hydraulic.

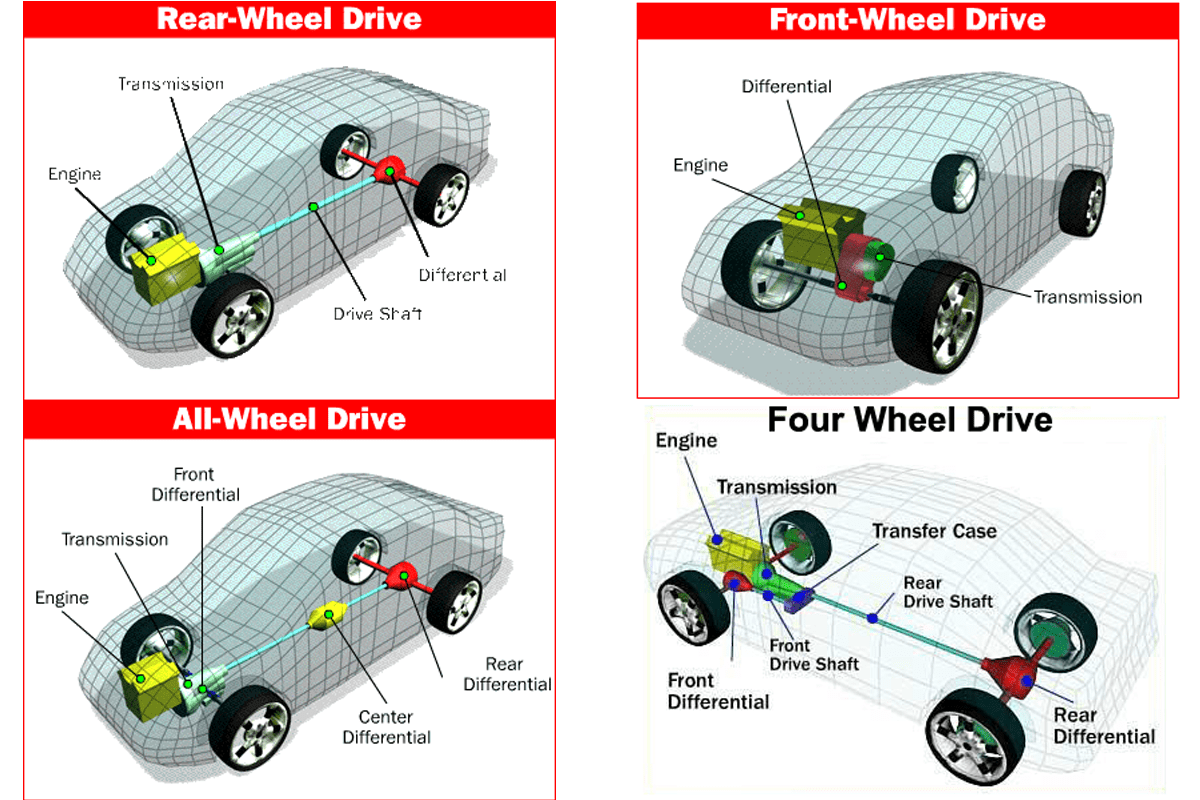

Symbols and Diagram Interpretation

Reading diagrams requires understanding the symbology. While conventions can vary slightly, here are some common symbols:

- Solid Lines: Represent mechanical connections, like driveshafts or axle shafts.

- Dashed Lines: Represent electrical or hydraulic connections, like wiring harnesses or hydraulic lines.

- Circles: Often represent gears or rotating components.

- Squares/Rectangles: Can represent electronic control units, sensors, or actuators.

- Arrows: Indicate the direction of power flow or fluid flow.

- Colors: Often used to distinguish different systems or components. For instance, blue might represent hydraulic lines, while red represents electrical wiring.

Understanding these symbols allows you to trace the flow of power through the AWD system and identify the relationships between different components.

How It Works: A Simplified Explanation

The fundamental principle of AWD is to distribute power to all four wheels. This provides superior traction compared to two-wheel drive, especially on slippery surfaces.

- Power Generation: The engine generates power.

- Power Transmission: The transmission transfers that power and modifies torque.

- Power Split: The transfer case (or PTU) splits the power between the front and rear axles. The method of splitting the power is key. Some systems use gears for a fixed split. Others use clutches (like a multi-plate wet clutch) or viscous couplings that can vary the torque distribution based on wheel slip. Electronically controlled systems use sensors and a control unit to dynamically adjust the torque split.

- Differential Action: The front and rear differentials allow the wheels on each axle to rotate at different speeds, preventing binding when turning.

- Wheel Rotation: The axle shafts transfer the power from the differentials to the wheels, propelling the vehicle forward.

Key Concept: Torque distribution is the heart of AWD. Systems vary on how they achieve this distribution, influencing their performance characteristics.

Some AWD systems are "full-time," meaning all four wheels are always receiving power. Other systems are "part-time," meaning the driver can manually engage or disengage the AWD system. And finally, many modern systems are "automatic," meaning they engage and disengage the AWD system automatically based on sensor inputs like wheel slip or throttle position.

Real-World Use: Basic Troubleshooting Tips

Here are some common AWD system issues and basic troubleshooting tips:

- Clunking Noises: Could indicate worn U-joints in the driveshafts, a failing transfer case, or differential issues. Inspect the U-joints for play and lubricate them. Check the transfer case and differentials for leaks and proper fluid levels.

- Vibrations: Could be caused by a bent driveshaft, unbalanced tires, or worn wheel bearings. Visually inspect the driveshafts for damage. Have your tires balanced. Check the wheel bearings for play.

- Wheel Slip: If the AWD system isn't engaging properly, you might experience excessive wheel slip. Check the AWD system's fuses and relays. If your system has an electronic control unit, scan it for error codes.

- Warning Lights: An illuminated AWD warning light indicates a problem with the system. Scan the system for error codes and consult your vehicle's service manual for diagnosis.

- Difficulty Turning (Binding): If you experience binding while turning on dry pavement, it could indicate a problem with the transfer case or a differential that's not allowing the wheels to rotate at different speeds. This is often an indication of a mismatch in tire sizes or incorrect fluid in the transfer case or differential.

Remember, always consult your vehicle's service manual for specific troubleshooting procedures and torque specifications.

Safety: Highlighting Risky Components

Working on AWD systems involves some inherent risks. Here are some key safety considerations:

- Driveshafts: Rotating driveshafts can cause serious injury. Always disconnect the battery and ensure the vehicle is properly supported before working near them.

- Springs: Some AWD systems use coil springs within the suspension. These springs are under immense pressure and can cause serious injury if released improperly. Use proper spring compressors when working with coil springs.

- Hydraulic Systems: Some AWD systems use hydraulic components. Relieve pressure in hydraulic systems before disconnecting lines. Hydraulic fluid can be harmful if it comes into contact with skin or eyes.

- Electrical Components: Electronic AWD systems contain numerous electrical components. Disconnect the battery before working on electrical components to prevent shocks or short circuits.

- Heavy Components: Transfer cases, differentials, and driveshafts are heavy. Use proper lifting equipment and techniques to prevent injury.

Always wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and sturdy footwear, when working on your vehicle.

AWD systems can be complex, but with a solid understanding of the core components, how they work, and the associated safety precautions, you can confidently tackle many repairs and modifications yourself. Remember to consult your vehicle's service manual for specific instructions and torque specifications.

We have the AWD system diagram file that complements this article. This diagram provides a visual representation of the system, including component locations and connections. It's a valuable resource for anyone working on their own vehicle. Contact us to get your copy!