What Is All Wheel Drive System

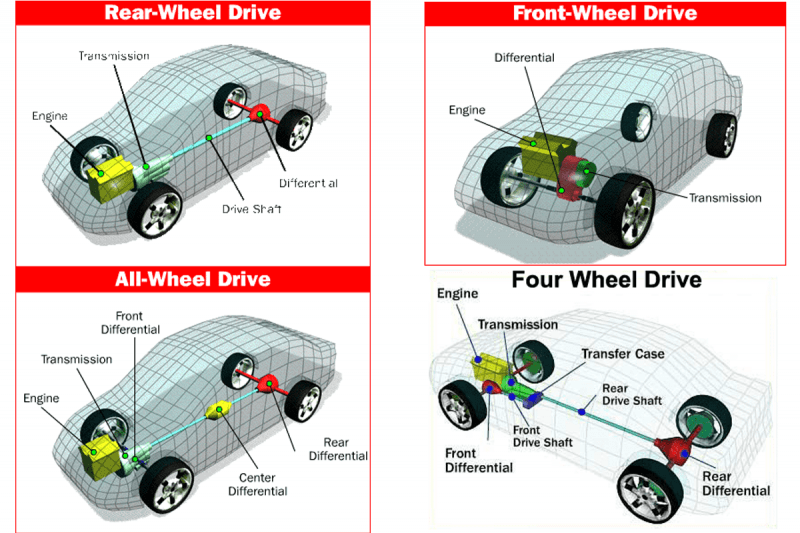

Alright, let's dive deep into the world of All-Wheel Drive (AWD) systems. This isn't just about getting better traction in the snow; understanding how your AWD system works can be invaluable for diagnosing issues, planning modifications, or even just appreciating the engineering marvel under your car. We'll break down the components, the operating principles, and even some basic troubleshooting. And remember, we have a detailed diagram available for download to help you visualize everything as we go.

Why Understanding Your AWD System Matters

Whether you're planning a lift kit, replacing a worn-out CV joint, or simply trying to figure out why your gas mileage has tanked, a solid understanding of your AWD system is crucial. Knowing the components, their function, and how they interact will empower you to diagnose problems accurately, perform maintenance confidently, and even plan performance upgrades effectively. For example, understanding the type of center differential in your system will inform your tire rotation strategy and influence your choice of aftermarket performance parts.

Key Specs and Main Parts

AWD systems come in various flavors, but they all share a few core components. Let's break them down:

- Engine: The heart of the system, providing the power that ultimately drives all four wheels.

- Transmission: Modifies the engine's torque and speed for optimal performance.

- Transfer Case (or Power Transfer Unit - PTU): This is often the key differentiating component between AWD systems. The transfer case splits power between the front and rear axles. In some systems, it's a simple gear-driven mechanism, while in others, it's a sophisticated electronically controlled unit. A PTU is generally smaller and found in transverse engine vehicles, while a larger transfer case is generally found in longitudinal engine vehicles.

- Front and Rear Differentials: These allow the left and right wheels on each axle to rotate at different speeds, crucial for turning. A standard open differential sends power to the wheel with the least resistance, which can be problematic in low-traction situations. Limited-slip differentials (LSDs) and locking differentials are used to overcome this issue.

- Driveshafts/Half-shafts: These rotating shafts transmit power from the transfer case and differentials to the wheels. Driveshafts typically connect the transfer case to the rear differential, while half-shafts (also known as axle shafts) connect the differentials to the wheels themselves.

- Axles: The final component connecting the half shafts to the wheels.

- Wheel Speed Sensors: These sensors, part of the ABS (Anti-lock Braking System), also play a crucial role in some AWD systems by providing data to the AWD control module for torque distribution.

- AWD Control Module (if applicable): Some AWD systems are electronically controlled, using sensors and algorithms to optimize torque distribution based on driving conditions.

Types of AWD Systems

Beyond the components, it's essential to understand the different types of AWD systems. Here's a quick overview:

- Full-Time AWD: Power is constantly sent to all four wheels. These systems often use a center differential to allow for speed differences between the front and rear axles.

- Part-Time AWD: The driver manually engages the AWD system, typically for off-road use. These systems often lack a center differential and should only be used on slippery surfaces to avoid drivetrain binding.

- Automatic/On-Demand AWD: The system operates primarily in two-wheel drive, and automatically engages AWD when wheel slip is detected. These systems often use a viscous coupling or electronically controlled clutch to transfer power to the other axle.

Decoding the AWD Diagram

The diagram we have for you uses common symbols to represent the various components of the AWD system. Let's decode some of the key visual elements:

- Solid Lines: Represent mechanical connections, such as driveshafts and axles. Thicker lines often indicate heavier-duty components.

- Dashed Lines: Typically represent electronic or hydraulic connections, such as wiring harnesses or fluid lines.

- Colors: Colors often represent different systems or fluid types. For example, blue might represent hydraulic fluid, while red might represent transmission fluid. Check the diagram's legend for specific color coding.

- Icons: Icons are used to represent specific components, such as differentials, transfer cases, and sensors. Familiarize yourself with these icons to quickly identify components on the diagram.

How It Works: From Engine to Wheel

The basic principle is simple: the engine generates power, which is then transmitted through the transmission to the transfer case. The transfer case splits the power between the front and rear axles. The differentials on each axle then allow the left and right wheels to rotate at different speeds. Let's consider an example of an automatic AWD system. When the system detects front wheel slip (through the ABS wheel speed sensors), the AWD control module activates a clutch pack in the transfer case, diverting torque to the rear wheels. The amount of torque sent to the rear can vary depending on the system and the severity of the wheel slip. Sophisticated systems can even redistribute torque between the left and right wheels on an axle using electronic stability control (ESC) to further enhance traction and stability.

Real-World Use and Basic Troubleshooting

So, how does this knowledge translate to real-world use? Here are a few basic troubleshooting tips:

- Unusual Noises: Grinding, clicking, or whining noises can indicate problems with the transfer case, differentials, or CV joints. Try to pinpoint the location of the noise to narrow down the possible causes.

- Vibrations: Vibrations, especially at certain speeds, can be caused by unbalanced driveshafts or worn-out CV joints. A failing center support bearing on a long driveshaft can also cause vibrations.

- Warning Lights: Pay attention to any AWD warning lights on your dashboard. These lights often indicate a problem with the AWD control module or sensors.

- Tire Wear: Uneven tire wear can be a sign of a misalignment or a problem with the differentials. Maintaining proper tire pressure is also crucial for optimal AWD performance. For vehicles with full-time AWD, maintaining similar tread depth on all four tires is essential to prevent premature wear on the differentials and transfer case.

Safety First: Handling Risky Components

Working on an AWD system can be dangerous if you're not careful. Here are a few safety considerations:

- Driveshaft Safety: When working on the driveshaft, always support the vehicle securely on jack stands. A falling driveshaft can cause serious injury. Before disconnecting the driveshaft, mark its position relative to the differential flange to ensure proper reassembly and balance.

- Differential Disassembly: Disassembling a differential requires specialized tools and knowledge. If you're not comfortable with this task, it's best to leave it to a professional. The backlash and preload settings are critical for proper differential operation.

- High-Pressure Fluids: Some AWD systems use high-pressure hydraulic fluid. Always depressurize the system before disconnecting any fluid lines.

- Electrical Components: When working on electrical components, disconnect the battery to prevent accidental shorts.

Remember, this is a general overview. Your specific AWD system may have unique features and quirks. The detailed diagram we have available for download provides a more granular look at the components and their relationships. Use it in conjunction with your vehicle's service manual for the most accurate information. Don't hesitate to consult with a qualified mechanic if you're unsure about any aspect of working on your AWD system.

Now that you have a better understanding of AWD systems, you can confidently tackle maintenance, repairs, and even performance upgrades. Happy wrenching!

We have the detailed AWD diagram available for download to assist with your repairs and learning. Check the link at the bottom of the page.