What Is All Wheel Drive Vehicle

Alright, let's dive into the world of All-Wheel Drive (AWD) vehicles. As someone who's likely turned a wrench or two yourself, you probably already have a good grasp of the basics. But this article is all about getting into the nitty-gritty, the details that can make a difference when diagnosing a problem, planning a modification, or simply understanding how your car ticks.

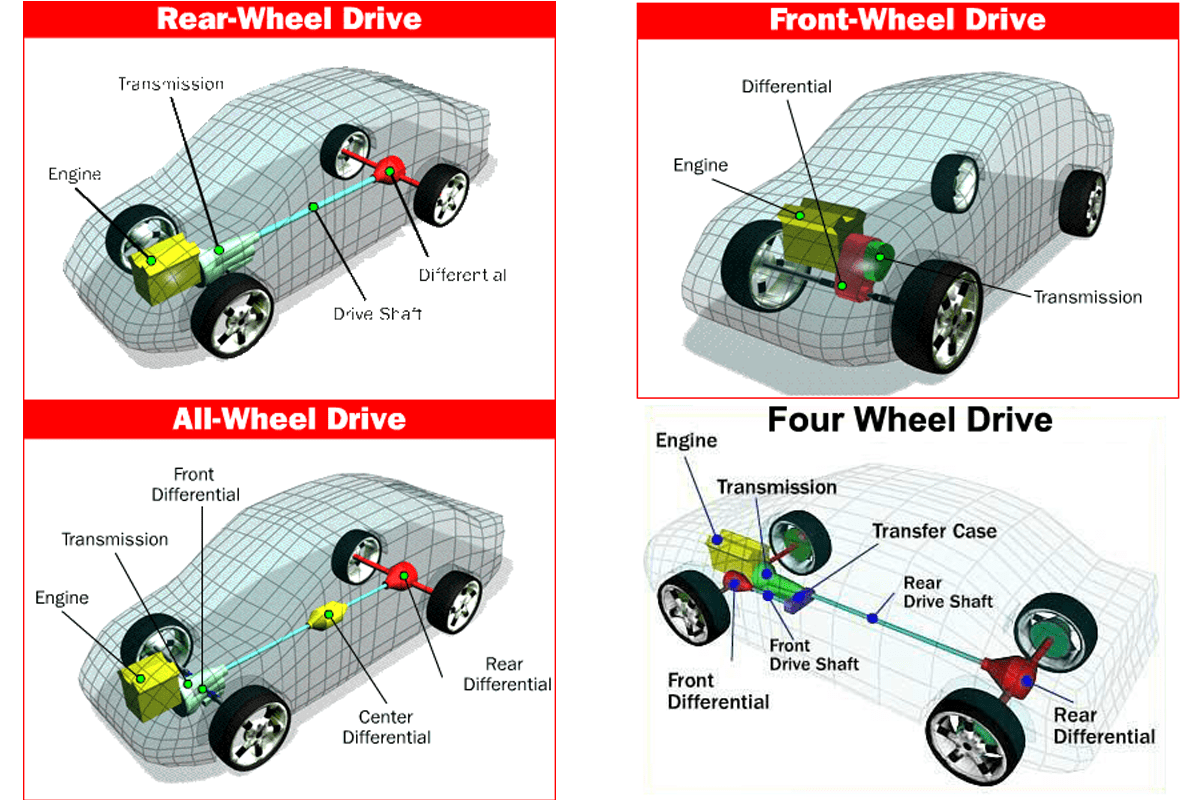

Purpose: Understanding AWD systems is crucial for anyone serious about car maintenance, modification, or repair. Knowing how the system works, the components involved, and potential failure points can save you time, money, and frustration. Whether you're upgrading your suspension, troubleshooting a drivetrain issue, or just want to understand your car better, this detailed explanation and accompanying diagram (available for download later) will be a valuable resource.

Key Specs and Main Parts of an AWD System

The core purpose of an AWD system is to distribute torque from the engine to all four wheels, providing enhanced traction compared to two-wheel drive (2WD) systems. This is especially beneficial in slippery conditions like snow, ice, mud, or gravel. However, not all AWD systems are created equal. They differ in their sophistication, torque distribution strategies, and suitability for different driving conditions. Here's a breakdown of the key components you'll find in most AWD setups:

1. Engine and Transmission

This is where the power originates. The engine generates torque, which is then transmitted to the transmission. The transmission's job is to convert the engine's output into usable power and speed ratios for the wheels.

2. Transfer Case

The transfer case is the heart of an AWD system. This unit takes the power from the transmission and splits it between the front and rear axles. The split can be fixed (e.g., 50/50) or variable, depending on the system type. It's essentially a secondary gearbox that redirects power. Different types exist, including chain-driven, gear-driven, and electronically controlled transfer cases.

3. Front and Rear Differentials

The differentials allow the wheels on the same axle to rotate at different speeds, which is essential when turning. Without a differential, the inner wheel would have to travel the same distance as the outer wheel during a turn, causing binding and tire slippage. A standard differential distributes torque equally, but this can be a problem in low-traction situations – if one wheel spins freely, all the torque goes to that wheel. This is where limited-slip differentials (LSDs) or electronic brake-based systems come into play.

4. Axles and Driveshafts

Axles connect the differential to the wheels, transmitting the power that makes them turn. Driveshafts connect the transmission to the transfer case and the transfer case to the differentials. These components are subject to considerable stress, especially in high-performance or off-road applications.

5. Electronic Control Unit (ECU) and Sensors

Many modern AWD systems are electronically controlled. The ECU monitors various sensors (wheel speed sensors, throttle position, steering angle, etc.) and adjusts the torque distribution based on driving conditions. This allows for a more dynamic and responsive AWD system.

6. Coupling (Clutch Pack, Viscous Coupling, or Electronic Clutch)

In some AWD systems, a coupling is used to engage or disengage the rear axle. This allows the vehicle to operate in 2WD mode under normal conditions, improving fuel economy. When needed, the coupling engages the rear axle, providing AWD capability. Examples include viscous couplings (using fluid resistance) and electronically controlled clutch packs.

Understanding AWD System Symbols

While our detailed diagram will visually illustrate these components, understanding common symbols is essential for interpreting schematics and technical documents. Here's a brief rundown:

- Solid Lines: Typically represent mechanical connections, such as driveshafts or axles. Thicker lines may indicate higher load-bearing components.

- Dashed Lines: Often denote electronic signals or vacuum lines used for control systems.

- Gear Symbols: Represent gears within the transmission, transfer case, or differentials. The number of teeth may be indicated.

- Clutch Symbols: Illustrate clutch plates or packs, indicating the presence of a coupling mechanism.

- Sensor Symbols: Represent various sensors (e.g., wheel speed sensors, ABS sensors).

- Color Coding: While not standardized across all diagrams, colors might be used to differentiate between hydraulic lines, electrical circuits, or different sections of the drivetrain. Refer to the diagram's legend for specific color interpretations.

How AWD Works: A Step-by-Step Explanation

Let's break down the power flow in a typical electronically controlled AWD system:

- The engine generates power, which is sent to the transmission.

- The transmission provides the appropriate gear ratio for the driving conditions.

- The transmission outputs power to the transfer case.

- The transfer case splits the torque between the front and rear driveshafts. The split can be fixed (e.g., 50/50) or variable. In variable systems, the ECU controls a coupling (clutch pack or viscous coupling) within the transfer case to adjust the torque distribution.

- The front and rear driveshafts transmit the torque to the front and rear differentials, respectively.

- The differentials allow the wheels on each axle to rotate at different speeds.

- The axles connect the differentials to the wheels, delivering the power to the ground.

- The ECU continuously monitors wheel speed sensors and other inputs. If it detects wheel slip, it can adjust the torque distribution by engaging or disengaging the coupling in the transfer case, sending more torque to the wheels with better traction.

Real-World Use: Basic Troubleshooting Tips

Here are a few common AWD-related issues and how to diagnose them:

- Unusual Noises: Grinding, whining, or clunking noises from the drivetrain could indicate worn bearings, damaged gears in the transfer case or differentials, or failing CV joints on the axles.

- Vibrations: Vibrations, especially at higher speeds, could be caused by worn U-joints on the driveshafts, unbalanced driveshafts, or damaged axles.

- AWD Warning Light: A lit AWD warning light on your dashboard indicates a problem with the AWD system. Use an OBD-II scanner to read the error codes and pinpoint the issue. Common causes include faulty wheel speed sensors, issues with the transfer case, or problems with the ECU.

- Poor Traction: If you're experiencing poor traction in slippery conditions, it could be due to a failing coupling in the transfer case, worn differentials, or problems with the electronic control system.

Safety Considerations

Working on an AWD system can be dangerous if proper precautions aren't taken. Here are a few key safety points:

- Driveshafts: Driveshafts can store rotational energy. Always chock the wheels, engage the parking brake, and disconnect the battery before working on the drivetrain.

- Differentials: Differential fluids can be hot and may contain harmful chemicals. Wear gloves and eye protection when working with differentials.

- Transfer Case: The transfer case is a complex unit. If you're not comfortable disassembling it yourself, it's best to take it to a professional.

- Electronic Components: Disconnect the battery before working on any electrical components of the AWD system.

Always consult your vehicle's repair manual for specific instructions and torque specifications. Improper repairs can damage the AWD system and compromise safety.

Remember that AWD doesn't make your vehicle invincible. It improves traction, but it doesn't change the laws of physics. Drive safely and responsibly, especially in challenging conditions.

Now that you have the know-how to navigate the intricacies of AWD systems, remember that a detailed diagram can be immensely helpful. We have the detailed diagram in hand, which you can download HERE.