What Is An All Wheel Drive

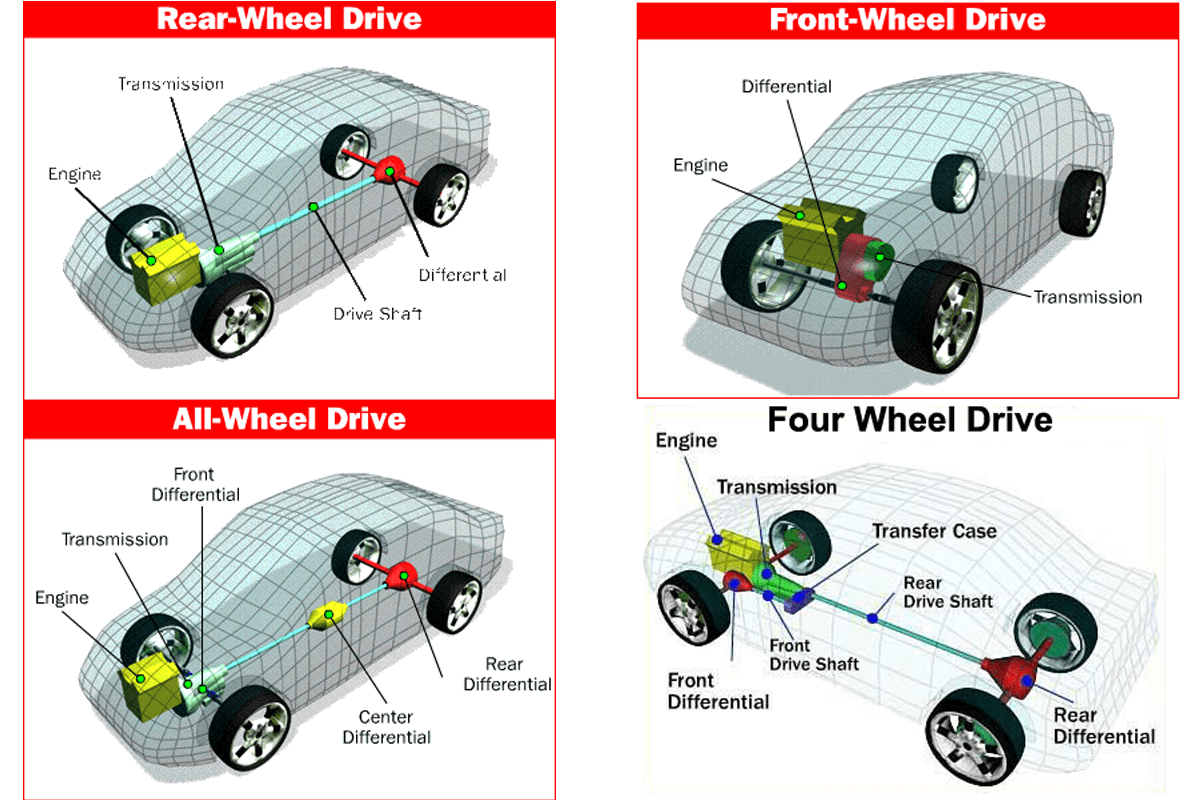

Alright, let's dive into the world of All-Wheel Drive (AWD) systems. This isn't your basic front-wheel or rear-wheel drive; AWD is a different beast entirely. Understanding how it works is crucial for more than just bragging rights. Knowing the components and functionality empowers you to diagnose issues, perform basic maintenance, and even consider modifications down the line. We'll break down the key aspects, giving you the knowledge to tackle AWD problems with confidence.

Purpose: Why Understand AWD?

Why bother learning about AWD? Well, consider this: a malfunctioning AWD system can lead to reduced traction, poor fuel economy, and even damage to expensive components. Understanding the system allows you to:

- Diagnose Problems Early: Identify unusual noises, vibrations, or handling issues that could indicate an AWD problem.

- Perform Basic Maintenance: Check fluid levels, inspect components, and potentially replace worn parts.

- Make Informed Decisions: Choose the right tires, understand the limitations of your system, and decide on appropriate modifications.

- Communicate Effectively: Talk to your mechanic with confidence, explaining the symptoms and potential causes you suspect.

Having a detailed understanding of your AWD system, especially coupled with a technical diagram (which we can provide - more on that later), is an invaluable asset for any serious DIY mechanic or car enthusiast.

Key Specs and Main Parts

AWD systems, while diverse, share common components. Let's look at the major players:

- Engine: Provides the initial power. Essential, obviously!

- Transmission: Transmits power from the engine, and allows gear changes.

- Transfer Case (or Power Transfer Unit - PTU): This is the heart of many AWD systems. It splits the engine's power between the front and rear axles. Some vehicles use a PTU which is typically lighter duty than a traditional transfer case.

- Front Differential: Distributes power to the front wheels. A differential allows wheels to rotate at different speeds, which is crucial for turning.

- Rear Differential: Distributes power to the rear wheels, same concept as the front.

- Driveshafts (or Propeller Shafts): Connect the transfer case to the front and rear differentials, transmitting power.

- Axle Shafts: Connect the differentials to the wheels.

- Viscous Couplings/Clutches (Optional): Some systems use these to control the amount of torque sent to each axle. Viscous couplings contain a fluid that thickens when sheared, providing variable torque transfer. Clutches are electronically controlled.

- Sensors and Control Modules (Optional): More sophisticated AWD systems use sensors (wheel speed, throttle position, etc.) and control modules (ECUs) to dynamically adjust torque distribution based on driving conditions.

Key specs include the torque split ratio (e.g., 50/50, 60/40 front/rear), the type of coupling or clutch used, and the response time of the system.

Understanding Symbols (In a Technical Diagram)

Technical diagrams use standardized symbols. While they vary slightly between manufacturers, some common ones include:

- Solid Lines: Represent mechanical connections, like driveshafts or axles.

- Dashed Lines: Represent control lines or electrical connections, such as wiring harnesses for sensors.

- Arrows: Indicate the direction of power flow or fluid flow.

- Circles: Often represent gears or bearings.

- Rectangles: Can represent control modules, sensors, or actuators.

- Color Coding: Some diagrams use color to differentiate between different systems (e.g., blue for hydraulic, red for electrical).

Refer to the diagram's legend for specific symbol definitions. A good diagram will have a comprehensive key.

How It Works: Power Flow and Torque Distribution

The basic principle is this: the engine's power goes to the transmission, then to the transfer case. The transfer case splits the power, sending a portion to the front differential and a portion to the rear differential via driveshafts. The differentials then distribute the power to the individual wheels.

Different AWD systems achieve this split in different ways:

- Full-Time AWD: Constantly sends power to all four wheels. The torque split can be fixed or variable. A fixed split, like 50/50, sends an equal amount of torque to both axles at all times. Variable systems use viscous couplings, clutches, or electronic controls to adjust the torque distribution based on wheel slip, throttle input, and other factors.

- Part-Time AWD: Typically found on trucks and older SUVs. The driver manually engages AWD, locking the front and rear axles together. This is suitable for off-road use but can cause binding on paved surfaces.

- Automatic AWD (or On-Demand AWD): Normally operates in front-wheel or rear-wheel drive, but automatically engages AWD when wheel slip is detected. These systems often use electronically controlled clutches to engage the rear axle when needed.

The key is torque distribution. The goal is to send power to the wheels with the most traction, maximizing grip and preventing wheel spin. Sophisticated systems can even vary the torque split between individual wheels, improving handling in cornering situations.

Real-World Use: Basic Troubleshooting

Here are some basic troubleshooting tips for common AWD problems:

- Unusual Noises: Grinding, clunking, or whining noises from the transfer case or differentials can indicate worn bearings, gears, or low fluid levels.

- Vibrations: Vibrations, especially at higher speeds, can be caused by worn U-joints in the driveshafts or an unbalanced driveshaft.

- Poor Traction: If you're experiencing wheel spin in conditions where AWD should provide good traction, check the fluid levels in the transfer case and differentials. Also, inspect the clutches or viscous couplings for wear or damage.

- Warning Lights: Many modern vehicles have AWD warning lights. If the light is on, consult your owner's manual or have the system scanned for error codes.

- Binding: If you experience binding or difficulty turning on paved surfaces in 4WD (especially on older part-time systems), disengage the system immediately. Continuing to drive in this condition can damage the drivetrain.

Remember, a thorough visual inspection is always the first step. Look for leaks, damage, and worn components.

Safety: Risky Components

Working on AWD systems involves some inherent risks:

- Driveshafts: These rotate at high speeds and can cause serious injury if they become detached. Always secure the vehicle properly before working on the drivetrain.

- Differentials: Contain gears that can pinch fingers or hands. Be careful when disassembling and reassembling differentials.

- High Torque: Many AWD components are subjected to high torque loads. Use the correct tools and torque specifications when tightening bolts.

- Fluid Handling: Differential and transfer case fluids can be messy and contain harmful chemicals. Wear gloves and eye protection.

- Vehicle Stability: Never work under a vehicle supported only by a jack. Use jack stands.

Always disconnect the negative battery terminal before working on electrical components in the AWD system.

Finally, remember that we have a detailed technical diagram available that complements this information. It can be a valuable tool for understanding the specific layout and components of your AWD system. Download it to enhance your troubleshooting and repair capabilities.