What Is Cvt In A Car

Okay, so you're diving into the world of transmissions and have stumbled across "CVT." Let's break down what a CVT, or Continuously Variable Transmission, is, how it functions, and what you need to know about it from a DIYer's perspective. This isn't your grandfather's automatic; it's a different beast entirely.

Purpose of Understanding CVTs

Why bother understanding CVTs? Well, for a few key reasons:

- Diagnosis and Repair: Many common transmission issues can be addressed with a basic understanding of the system. Knowing how a CVT *should* work makes it easier to identify when it *isn't* working correctly.

- Modifications: While not as common as with traditional transmissions, understanding the principles of operation is crucial if you're considering any performance modifications or aftermarket enhancements.

- Maintenance: Properly maintaining a CVT is critical to its longevity. Knowing what's going on inside allows you to make informed decisions about fluid changes, inspections, and preventative care.

- General Automotive Knowledge: Just expanding your overall knowledge of how different car systems work is a rewarding pursuit.

Key Specs and Main Parts

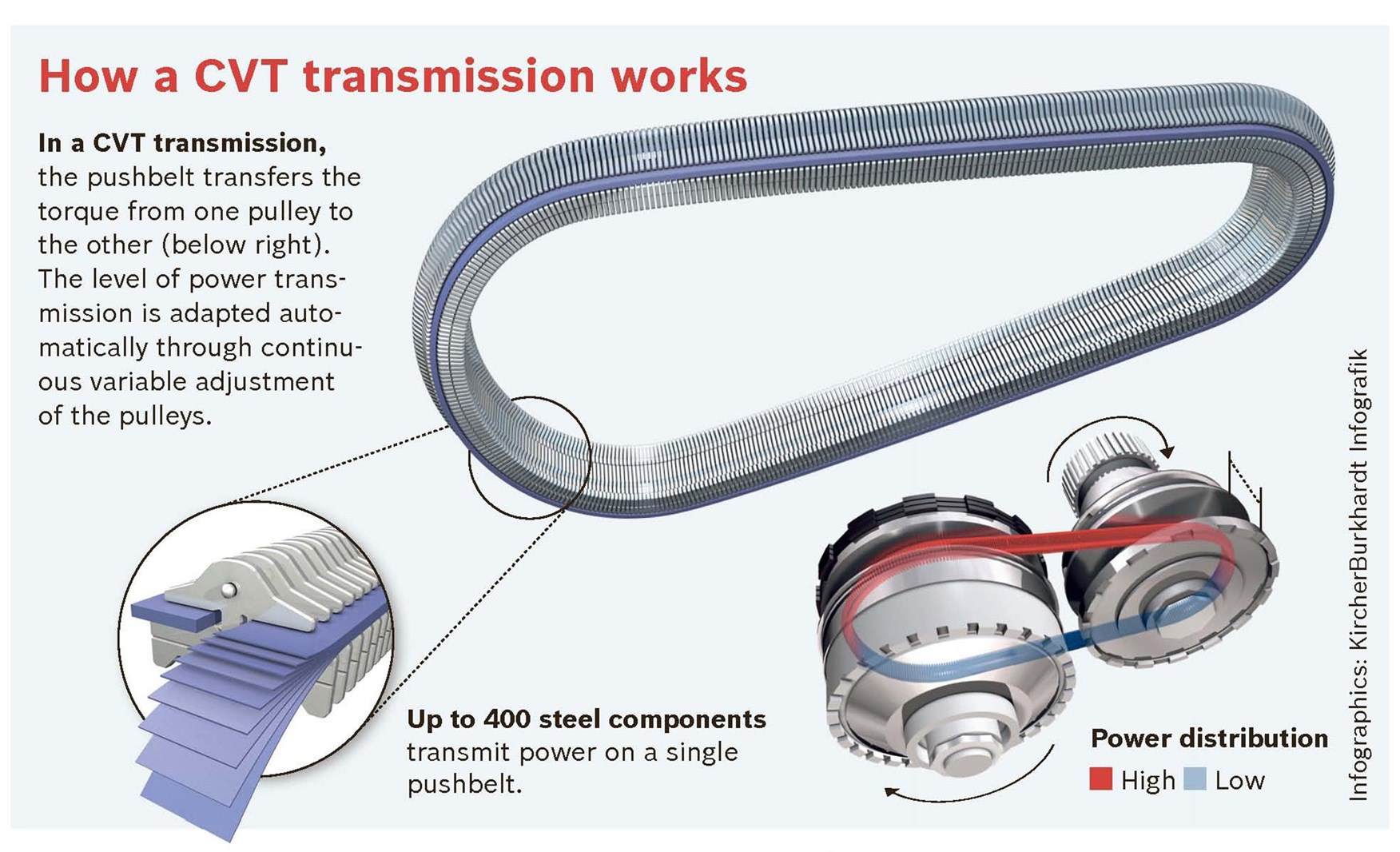

The core principle of a CVT is to provide a seamless, continuous range of gear ratios, unlike traditional stepped gear transmissions. Instead of distinct gears, a CVT uses a system to create an infinite number of ratios within a defined range.

Main Components:

- Input Pulley (Drive Pulley): Connected to the engine, this pulley receives power and transfers it to the belt or chain.

- Output Pulley (Driven Pulley): Connected to the differential and ultimately the wheels, this pulley receives power from the belt or chain.

- Belt or Chain: This is the crucial element that transmits power between the two pulleys. Most CVTs use a high-strength, flexible metal belt or chain designed to withstand the extreme stresses and friction.

- Hydraulic Control System: This system uses hydraulic pressure to control the effective diameter of the pulleys, thereby changing the gear ratio. It's essentially the "brain" of the CVT.

- Sensors: Various sensors (speed sensors, pressure sensors, temperature sensors) provide feedback to the control system about the operating conditions of the CVT.

- Valve Body: This assembly contains solenoids and valves that regulate the flow of hydraulic fluid within the control system.

- Torque Converter (in some designs): Similar to a traditional automatic transmission, a torque converter may be used to provide smooth starts and torque multiplication at low speeds. However, some modern CVTs now use a wet clutch system in place of the torque converter for improved efficiency.

- CVT Fluid: Specially formulated fluid is critical for lubricating, cooling, and providing hydraulic pressure within the CVT. Using the wrong fluid can quickly damage a CVT.

How It Works

Imagine two cones facing each other, connected by a belt. If you move the belt closer to the narrow end of one cone and the wide end of the other, you change the gear ratio. That's the basic concept. In a real CVT, these "cones" are actually variable-diameter pulleys controlled by hydraulic pressure.

Here's a more detailed breakdown:

- Engine Input: The engine provides power to the input pulley.

- Ratio Adjustment: The hydraulic control system, based on inputs from sensors and the driver's throttle input, adjusts the effective diameter of the input and output pulleys. This is done by moving the sides of the pulleys closer together or further apart.

- Power Transfer: The belt or chain transfers power from the input pulley to the output pulley at the selected gear ratio.

- Output to Wheels: The output pulley transmits power to the differential and ultimately to the wheels.

- Continuous Adjustment: The hydraulic control system continuously adjusts the pulley diameters to maintain the optimal gear ratio for the desired speed and load.

The beauty of this system is that it can keep the engine operating at its optimal RPM for maximum efficiency or power, regardless of vehicle speed. This is why CVTs often provide better fuel economy than traditional automatic transmissions.

Real-World Use - Basic Troubleshooting

CVTs, like any complex system, can experience problems. Here are a few basic troubleshooting tips:

- Slipping: If the engine revs up without a corresponding increase in vehicle speed, the CVT may be slipping. This could be due to worn belt/chain, low fluid, or a failing hydraulic control system.

- Jerky or Erratic Behavior: This could be caused by faulty sensors, a malfunctioning valve body, or contaminated CVT fluid.

- Noise: Unusual noises, such as whining or grinding, can indicate internal damage to the CVT.

- Check Engine Light: Any problems with the CVT can trigger the check engine light. Use an OBD-II scanner to retrieve the diagnostic trouble codes (DTCs).

Important: Always check the CVT fluid level and condition as a first step in troubleshooting. Low or contaminated fluid is a common cause of CVT problems. Also, ensure that you're using the correct type of CVT fluid specified by the manufacturer. Using the wrong fluid can cause serious damage.

Safety – Highlight Risky Components

Working on a CVT can be dangerous if you're not careful. Here are some safety considerations:

- High Pressure: The hydraulic control system operates at high pressure. Relieve the pressure before disconnecting any lines or components.

- Hot Fluid: CVT fluid can be extremely hot. Allow the CVT to cool down before draining or servicing it.

- Moving Parts: Obviously, never work on the CVT while the engine is running or the vehicle is in motion.

- Specialized Tools: Some CVT repairs require specialized tools. Don't attempt to force anything or improvise tools.

- Fluid Disposal: Dispose of used CVT fluid properly. It's harmful to the environment.

Critical Safety Note: Due to the complexity of the CVT's hydraulic and electronic control systems, some repairs are best left to qualified professionals. Attempting repairs beyond your skill level can result in serious damage to the CVT or even personal injury.