What Is Cvt In Car Transmission

Alright, let's dive into the fascinating world of Continuously Variable Transmissions, or CVTs. As an experienced DIYer, understanding your car's transmission is crucial for effective maintenance, troubleshooting, and even considering performance modifications. This article will give you a solid grasp of CVTs, covering their components, operation, and potential issues. We’ll approach this like a trusted mechanic explaining the inner workings, using technical terms but always making sure the concepts are clear.

Why Understanding Your CVT Matters

Knowing the ins and outs of your CVT isn't just about sounding smart at the next car meet. A solid understanding will empower you to:

- Diagnose Problems Early: Identify unusual noises, slipping, or hesitation before they lead to major breakdowns.

- Perform Basic Maintenance: Properly change CVT fluid and inspect key components for wear.

- Make Informed Repair Decisions: Understand what a mechanic is explaining and avoid unnecessary repairs.

- Consider Performance Upgrades: Explore aftermarket CVT coolers or valve body modifications (though proceed with extreme caution!).

Key Specs and Main Parts of a CVT

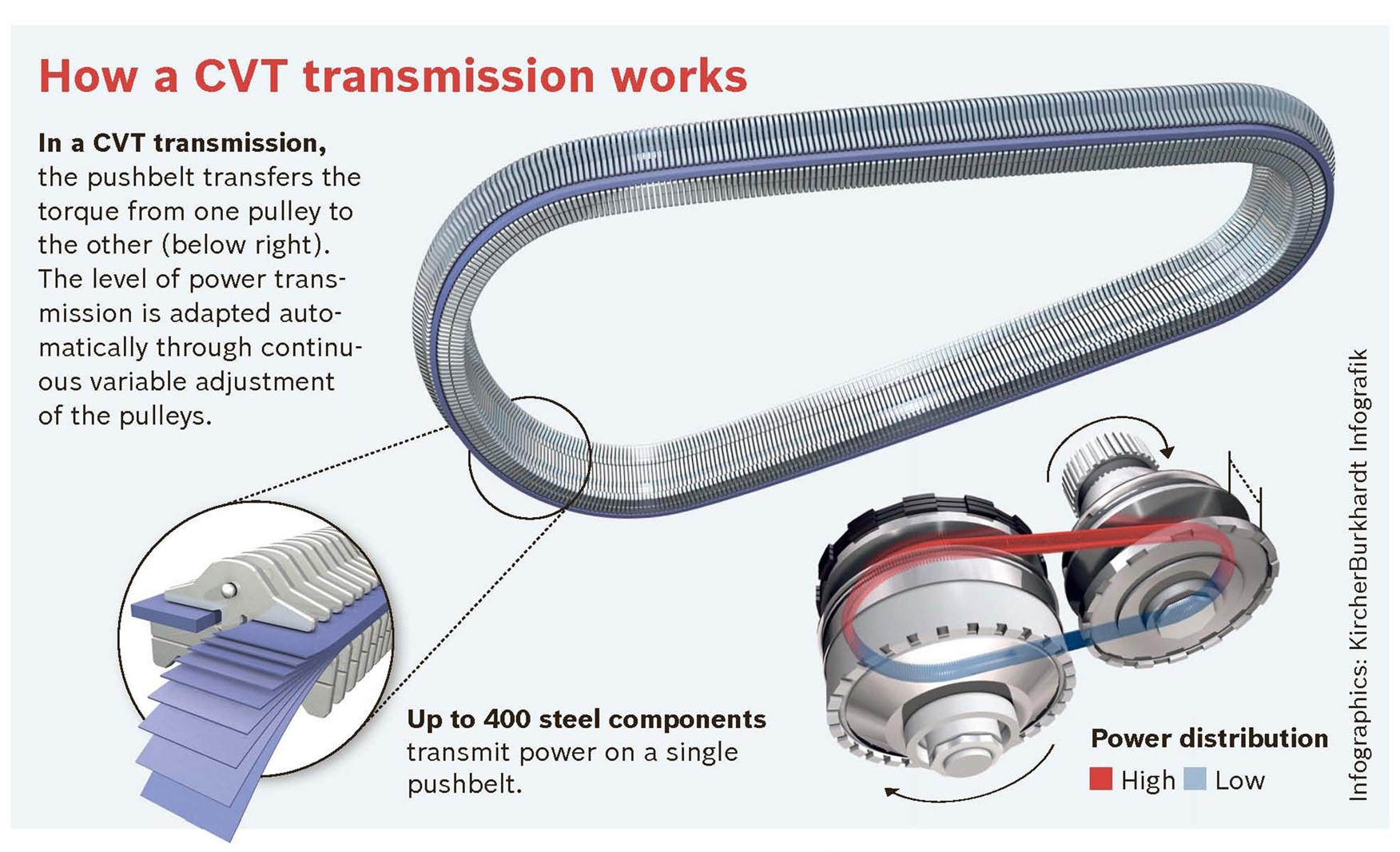

CVTs, unlike traditional automatic transmissions with fixed gear ratios, offer a virtually infinite number of gear ratios within a specific range. This is achieved through a unique system, typically involving:

- Input Shaft: Connects to the engine and transmits engine power to the CVT.

- Primary Pulley (Drive Pulley): This pulley is connected to the input shaft. It's comprised of two cone-shaped sheaves that can move together or apart.

- Secondary Pulley (Driven Pulley): Connected to the output shaft, which delivers power to the wheels. It also consists of two cone-shaped sheaves.

- Belt or Chain: A high-strength belt or chain (often made of steel) connects the primary and secondary pulleys. This belt/chain is the critical link in transmitting power. The design of this belt/chain and its material is one of the defining differences between CVT implementations.

- Hydraulic Control System: A complex network of valves, solenoids, and sensors that control the position of the pulley sheaves. This system adjusts the effective diameters of the pulleys, thereby changing the gear ratio.

- Transmission Control Unit (TCU): The "brain" of the CVT. The TCU receives input from various sensors (e.g., engine speed, vehicle speed, throttle position) and uses this information to control the hydraulic control system and optimize gear ratio.

- Torque Converter (Often Present): Similar to traditional automatics, many CVTs use a torque converter to provide smooth off-the-line acceleration and torque multiplication. Some newer designs use a wet clutch instead.

- Output Shaft: Transmits power from the secondary pulley to the differential and ultimately to the wheels.

How a CVT Works: The Magic of Variable Ratios

The core principle behind a CVT is deceptively simple: changing the effective diameters of two pulleys connected by a belt or chain. Here's a breakdown:

- The TCU's Role: The TCU constantly monitors various sensors and determines the optimal gear ratio based on driving conditions.

- Hydraulic Actuation: The TCU sends signals to the hydraulic control system. This system uses hydraulic pressure to move the sheaves of the primary and secondary pulleys.

- Ratio Adjustment: When the sheaves of the primary pulley move closer together, the belt/chain is forced to ride higher on the pulley, effectively increasing its diameter. Simultaneously, the sheaves of the secondary pulley move further apart, allowing the belt/chain to ride lower, decreasing its diameter. This creates a "low gear" ratio, providing more torque for acceleration.

- Smooth Transitions: As the vehicle accelerates, the TCU continuously adjusts the pulley positions, smoothly transitioning to higher gear ratios. This eliminates the distinct "shifts" found in traditional automatic transmissions, resulting in smoother and more fuel-efficient operation.

Imagine a bicycle with gears. In a traditional bike, you have a limited number of gears. A CVT is like a bike with an infinite number of gears, allowing for optimal efficiency at any speed.

Real-World Use: Basic Troubleshooting

While CVTs offer advantages, they can also present unique problems. Here are some basic troubleshooting tips:

- Slipping: If the engine revs high but the vehicle doesn't accelerate accordingly, the belt/chain might be slipping. This could be due to low fluid level, worn belt/chain, or internal damage.

- Jerky Acceleration: This could indicate a problem with the hydraulic control system or the TCU. Check for any diagnostic trouble codes (DTCs) using an OBD-II scanner.

- Unusual Noises: Whining or buzzing sounds could indicate low fluid level, a failing pump, or internal damage to the pulleys or belt/chain.

- Fluid Leaks: CVT fluid leaks should be addressed immediately to prevent damage. Check the seals around the pulleys, input shaft, and output shaft. Always use the correct CVT fluid specified for your vehicle. Using the wrong fluid can cause serious damage.

Safety: Proceed with Caution

Working on a CVT requires extreme caution. Here are some key safety considerations:

- High Pressure: The hydraulic control system operates at high pressure. Depressurize the system before disconnecting any lines or components. Refer to your vehicle's service manual for the proper procedure.

- Fluid Temperature: CVT fluid can get extremely hot. Allow the system to cool down before working on it to avoid burns.

- Belt/Chain Tension: The belt/chain is under significant tension. Do not attempt to disassemble the pulleys without proper tools and knowledge. Serious injury can result.

- Torque Converter: If your CVT uses a torque converter, remember it is filled with fluid and can be heavy. Support it properly when removing it to prevent dropping it and causing injury or damage.

- Electronics: The TCU and associated sensors are sensitive electronic components. Handle them with care and avoid static electricity.

Important Safety Note: Due to the complexity and precision of CVT components, major repairs should ideally be left to qualified technicians. Incorrect assembly or adjustments can lead to catastrophic failure. If you are unsure about any procedure, consult a professional.

Final Thoughts

Understanding your CVT is a valuable asset for any car enthusiast. By grasping the fundamentals of its operation and potential issues, you'll be better equipped to maintain your vehicle, diagnose problems, and make informed decisions about repairs or upgrades. While major repairs should be left to the professionals, a solid understanding will help you navigate the world of CVTs with confidence.