What Is Drive Belt In Car

So, you're diving into the world of automotive maintenance, and the drive belt has caught your eye. Good choice! Understanding this unassuming rubber strap is crucial for keeping your engine accessories humming. Think of it as the silent workhorse of your car, responsible for a lot more than you might realize. This article will break down everything you need to know, from its purpose to troubleshooting.

Purpose of Understanding the Drive Belt

Why should you bother understanding the drive belt system? Several reasons. First, preventative maintenance is key to avoiding breakdowns. Knowing how to inspect your belt for wear and tear can save you from being stranded on the side of the road. Second, for DIYers, replacing a drive belt is a relatively straightforward task that can save you a significant amount of money compared to taking it to a mechanic. Third, if you're modifying your engine – adding a supercharger, for example – you'll need to understand the belt system to ensure proper belt tension and routing. This understanding will prevent premature failure and potential damage to other components. Finally, a solid grasp of the drive belt system will allow you to better diagnose issues that arise from its failure, like a dead battery or overheating engine. We also have included a detailed diagram of the drive belt system which you can download at the end of this article.

Key Specs and Main Parts

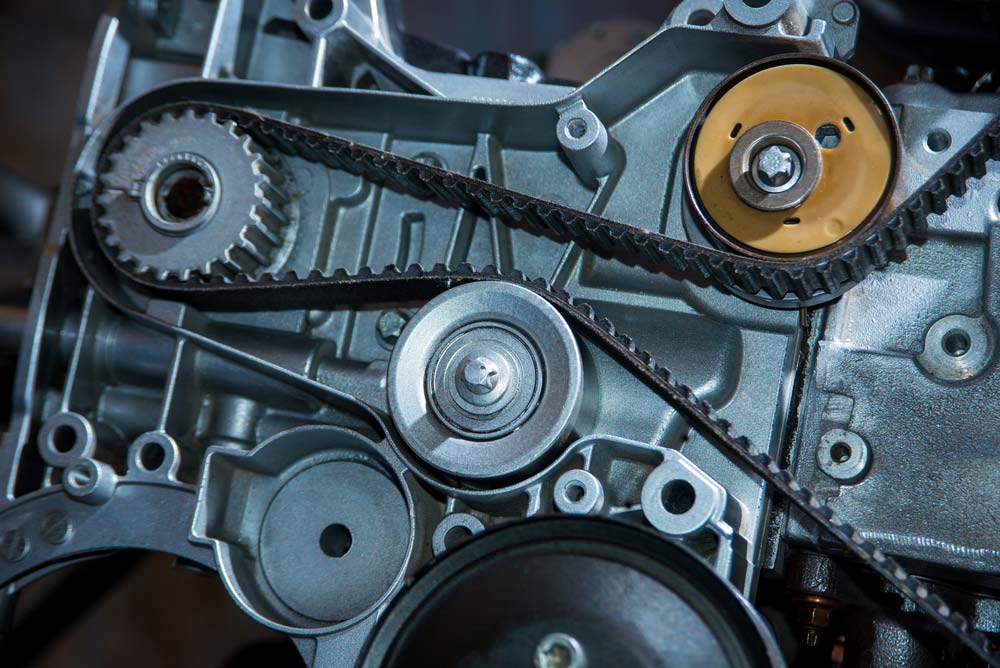

Let's start with the basics. The drive belt, also sometimes called the serpentine belt, is a continuous belt that wraps around various pulleys attached to engine accessories. Here's a rundown of the main components and specs:

- Drive Belt (Serpentine Belt): Made from reinforced rubber, typically EPDM (ethylene propylene diene monomer) or HNBR (hydrogenated nitrile butadiene rubber) for higher temperature applications. Key specs include:

- Length: Specified in millimeters or inches, crucial for proper fit.

- Width: Also specified in millimeters or inches, and corresponds to the pulley groove width.

- Number of Ribs: Corresponds to the number of grooves on the pulleys.

- Crankshaft Pulley (Harmonic Balancer): Connected directly to the crankshaft, this pulley drives the entire system. Its primary function, besides driving the belt, is to dampen torsional vibrations from the engine.

- Alternator Pulley: Driven by the belt, the alternator generates electricity to power your car's electrical system and charge the battery.

- Power Steering Pump Pulley: Provides hydraulic pressure to assist with steering.

- Air Conditioning Compressor Pulley: Engages and disengages to power the A/C compressor, providing cool air.

- Water Pump Pulley: Drives the water pump, circulating coolant to regulate engine temperature.

- Idler Pulley: A smooth pulley used to guide the belt and maintain proper tension.

- Tensioner Pulley: This is a spring-loaded pulley that automatically maintains the correct tension on the belt. It's absolutely crucial for belt life and proper accessory operation.

How It Works

The drive belt system operates on a simple principle: rotational force from the engine's crankshaft is transferred to the accessories via the belt. The crankshaft pulley, connected to the engine, spins, which in turn rotates the drive belt. This belt then drives the various accessory pulleys. The tensioner pulley maintains the correct tension on the belt, preventing slippage and ensuring efficient power transfer. If the belt slips, the accessories won't operate at their designed speed, leading to problems like a weak battery (alternator not charging properly), poor steering (power steering pump not working efficiently), or overheating (water pump not circulating coolant adequately).

Real-World Use – Basic Troubleshooting Tips

Okay, let's talk about what happens when things go wrong. Here are some common drive belt issues and how to diagnose them:

- Squealing Noise: This is the most common symptom. It usually indicates a loose or worn belt. Check the belt tensioner first. If it's functioning properly, inspect the belt for cracks, glazing (a shiny, hardened surface), or missing ribs.

- Cracked or Frayed Belt: Visual inspection is key. Cracks along the ribs or frayed edges indicate a deteriorating belt that needs replacement.

- Missing Ribs: Missing ribs will cause reduced accessory performance and eventually belt failure. Replace immediately.

- Accessory Failure: If your alternator isn't charging, power steering isn't working, or A/C isn't blowing cold, it could be a sign of a slipping or broken drive belt.

- Belt Dust: Excessive belt dust around the pulleys indicates belt wear and potential misalignment.

Important Note: Before replacing the belt, always check the pulleys for damage or misalignment. A damaged pulley can quickly destroy a new belt. Spin each pulley by hand (engine off, of course!) and listen for unusual noises or feel for roughness. Also, make sure the pulleys are aligned correctly; a misaligned pulley will cause premature belt wear.

Safety Considerations

Working around the drive belt system can be dangerous if you're not careful. Here are some essential safety precautions:

- Disconnect the Battery: Before working on any part of the electrical system, including the alternator, disconnect the negative terminal of the battery. This prevents accidental shocks or short circuits.

- Engine Off and Cool: Never work on the drive belt system with the engine running or hot. Wait for the engine to cool down completely.

- Keep Fingers and Clothing Clear: The rotating components of the drive belt system can cause serious injury. Keep your fingers, hands, and loose clothing away from the pulleys and belt.

- Use Proper Tools: Use the correct tools for the job, including a belt tensioner tool to release tension on the belt. Attempting to remove the belt without the proper tool can damage the tensioner or other components.

Understanding the Diagram

A drive belt diagram illustrates the specific routing of the belt around the various pulleys for your particular vehicle. These diagrams are crucial for proper installation. We have created a downloadable file of the drive belt system diagram. This diagram provides a clear visual representation of the belt's path, including the location of the tensioner and idler pulleys. Following the diagram ensures that the belt is routed correctly, preventing slippage and premature wear. In addition, the diagram includes torque specifications for the tensioner and other relevant hardware, ensuring that all components are properly tightened during installation.

The downloadable diagram uses these conventions:

- Solid Lines: Represent the drive belt itself.

- Arrows: Indicate the direction of belt travel.

- Different Colors: May be used to highlight specific sections of the belt or individual pulleys for clarity.

- Icons: Each pulley is labeled with an icon representing its function (e.g., alternator, water pump, etc.).

By carefully studying the diagram, you can confidently identify the correct routing for your drive belt and ensure a successful installation.

Ready to Download the Diagram?

You can download the detailed drive belt diagram here. Use it as a reference for repairs, maintenance, or modifications. Remember, understanding your car's systems is the first step towards confident DIY car care!