What Is Exhaust In A Car

Alright, let's dive into the often-overlooked but crucial system in your car: the exhaust. As a seasoned DIYer, understanding your exhaust system isn't just about making your car louder (though that can be part of it!). It's about optimizing performance, ensuring your engine breathes properly, diagnosing problems, and even making informed decisions when upgrading components. This article will break down the key aspects of a typical car exhaust system, its function, components, and how to troubleshoot common issues. We even have a detailed diagram you can download to reference as we go!

Purpose and Importance

The exhaust system serves several vital functions. Primarily, it removes the harmful combustion byproducts from your engine. These byproducts include carbon monoxide (CO), hydrocarbons (HC), and nitrogen oxides (NOx), all of which are not only bad for the environment but also dangerous to your health. Without a properly functioning exhaust, these gases would fill the cabin of your car, leading to serious health risks.

Beyond simply removing gases, the exhaust system also plays a role in:

- Reducing Noise: The muffler is specifically designed to dampen the loud explosions happening in your engine.

- Improving Fuel Efficiency: A properly designed exhaust can optimize exhaust flow, reducing backpressure and allowing the engine to run more efficiently.

- Boosting Engine Performance: By minimizing backpressure, the engine can expel exhaust gases more easily, allowing it to draw in more fresh air and fuel for combustion, leading to increased horsepower and torque.

Understanding how all these parts work together is critical for diagnosing issues like reduced power, poor fuel economy, or unusual noises. It also equips you to handle basic repairs or decide on suitable aftermarket upgrades. Having a good grasp on the exhaust system means you won't be at the mercy of a mechanic for simple fixes.

Key Specs and Main Parts

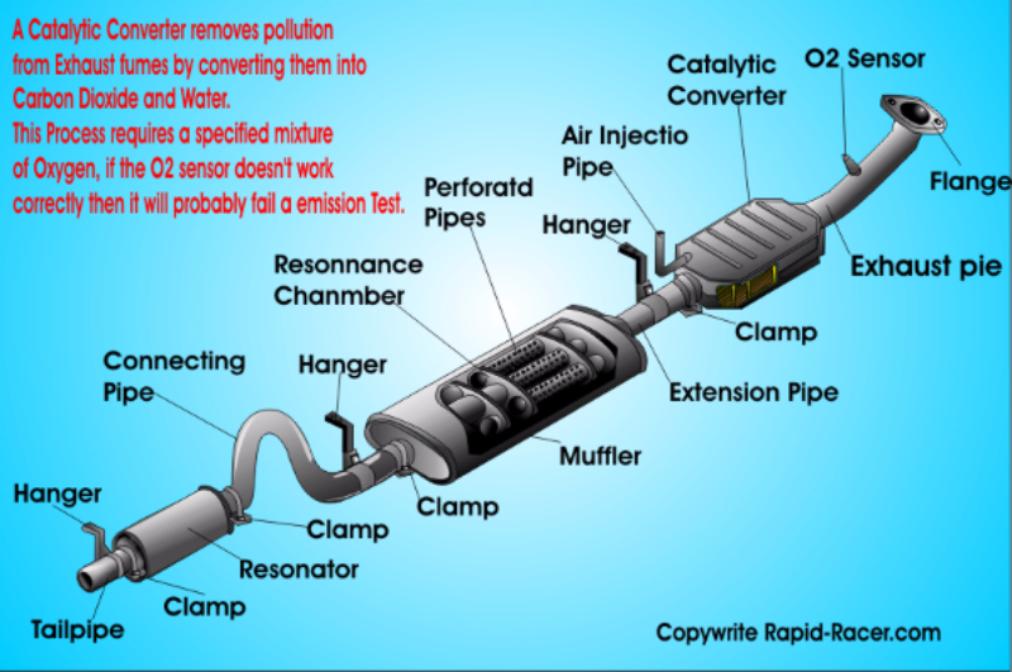

A typical exhaust system is comprised of several key components, each with a specific function:

- Exhaust Manifold: This is the first component that collects exhaust gases directly from the engine's cylinder head(s). It's usually made of cast iron or, in performance applications, stainless steel or tubular headers. The manifold's design significantly influences exhaust flow and can be a bottleneck for performance.

- Catalytic Converter: This is a crucial emissions control device. It uses chemical reactions to convert harmful gases (CO, HC, and NOx) into less harmful substances like carbon dioxide (CO2), water (H2O), and nitrogen (N2).

- Oxygen Sensors (O2 Sensors): These sensors measure the amount of oxygen in the exhaust stream, providing feedback to the engine control unit (ECU) to adjust the air-fuel mixture. There are typically two O2 sensors: one upstream (before) the catalytic converter and one downstream (after).

- Resonator (Optional): Some vehicles have a resonator, which is a pre-muffler device that further reduces noise and helps tune the exhaust note.

- Muffler: This is the primary noise reduction device. It uses a series of chambers and baffles to attenuate sound waves. Mufflers come in various designs, affecting the exhaust note (e.g., chambered, straight-through).

- Piping: These are the metal tubes that connect all the components together. They are usually made of steel, aluminized steel, or stainless steel. The diameter and bends in the piping affect exhaust flow.

- Exhaust Hangers: These rubber or metal mounts secure the exhaust system to the undercarriage of the car, preventing it from dragging and vibrating excessively.

Key specifications to consider when dealing with exhaust components include:

- Pipe Diameter: The diameter of the exhaust piping affects flow rate. Larger diameter pipes generally improve flow but can reduce backpressure, which can negatively impact low-end torque in some engines.

- Material: The material (steel, aluminized steel, stainless steel) affects durability and corrosion resistance. Stainless steel is the most durable but also the most expensive.

- Backpressure: This is the resistance to exhaust flow. While too much backpressure is detrimental, a certain amount is often necessary, especially in naturally aspirated engines, to maintain optimal engine performance.

Symbols and Conventions (Diagram)

While every diagram can vary slightly, here are some common conventions to look for in a typical exhaust system schematic:

- Lines: Solid lines generally represent the exhaust pipes themselves. Dashed lines might indicate connections to sensors or vacuum lines. The thickness of the line can sometimes suggest the pipe diameter.

- Colors: Colors are not always present but when used:

- Red: might indicate high-temperature areas.

- Blue: Might indicate areas with sensors or electronic components.

- Icons:

- O2 Sensor: Often depicted as a small rectangle with a wire coming out.

- Catalytic Converter: Often depicted as a larger rectangular box with a honeycomb pattern inside.

- Muffler: Often depicted as a cylinder with internal baffles drawn schematically.

- Arrows: Arrows will typically indicate the direction of exhaust flow.

How It Works

The exhaust system's operation is relatively straightforward. The combustion process within the engine cylinders creates high-pressure, hot exhaust gases. These gases are forced out of the cylinders through the exhaust valves and into the exhaust manifold. The exhaust manifold collects these gases from all cylinders and directs them into a single pipe.

From the manifold, the exhaust gases flow through the catalytic converter, where harmful pollutants are converted into less harmful substances. Oxygen sensors upstream and downstream of the converter monitor its efficiency and provide feedback to the ECU.

Next, the gases pass through the resonator (if equipped) and then the muffler, where noise is reduced. Finally, the exhaust gases are expelled out the tailpipe into the atmosphere.

The entire system is designed to efficiently remove exhaust gases while minimizing backpressure and noise. A well-designed system ensures optimal engine performance, fuel efficiency, and emissions control.

Real-World Use: Basic Troubleshooting Tips

Here are some common exhaust system problems and how to diagnose them:

- Loud Exhaust Noise: This could indicate a hole in the exhaust piping, a failing muffler, or a broken exhaust hanger. Visually inspect the system for rust, leaks, or damage. Listen carefully to pinpoint the location of the noise.

- Reduced Engine Power: This could be caused by a clogged catalytic converter or excessive backpressure due to a restriction in the exhaust system. Check for rust, dents, or collapsed pipes. A malfunctioning O2 sensor can also contribute to reduced power.

- Poor Fuel Economy: This can be caused by a leaking exhaust manifold gasket or a malfunctioning O2 sensor. A leak in the exhaust system *before* the O2 sensor will cause the sensor to read lean, causing the ECU to add more fuel.

- Check Engine Light: Many exhaust system problems, such as a failing catalytic converter or O2 sensor, will trigger the check engine light. Use an OBD-II scanner to retrieve the trouble codes and diagnose the issue. Common codes related to the exhaust system are P0420 (Catalyst System Efficiency Below Threshold) and codes related to O2 sensor failures.

- Smell of Exhaust Fumes Inside the Cabin: This is a serious safety issue and could indicate a leak in the exhaust manifold or exhaust piping. Have the system inspected immediately.

Safety

Working on the exhaust system can be hazardous due to the high temperatures involved. Always allow the exhaust system to cool completely before attempting any repairs. Even after the engine is off, the exhaust can remain extremely hot for a considerable amount of time. Use gloves and eye protection when working on the exhaust system.

Also, be aware of the potential for asbestos in older exhaust systems (particularly in exhaust manifold gaskets). If you suspect asbestos, take appropriate precautions, such as wearing a respirator and wetting down the material before handling it.

Finally, when welding on exhaust components, be sure to disconnect the battery to prevent damage to the vehicle's electrical system.

Now that you have a solid understanding of your car's exhaust system, you're better equipped to diagnose problems, perform basic repairs, and even consider performance upgrades. To further aid you in your journey, we have the detailed diagram of a generic exhaust system available for download. This diagram will provide a visual reference to all the components we have discussed, making it easier to understand their placement and function within the system. Good luck, and wrench safely!