What Is Front Wheel Drive Cars

Alright, let's dive into the world of Front-Wheel Drive (FWD) vehicles. This is a crucial topic for any serious DIY mechanic or car enthusiast. Understanding FWD systems will empower you to diagnose issues more effectively, perform routine maintenance with confidence, and even consider modifications to enhance performance or efficiency. We've got a detailed diagram available for download (link at the end), but let's first build a solid foundation of knowledge.

Key Specs and Main Parts

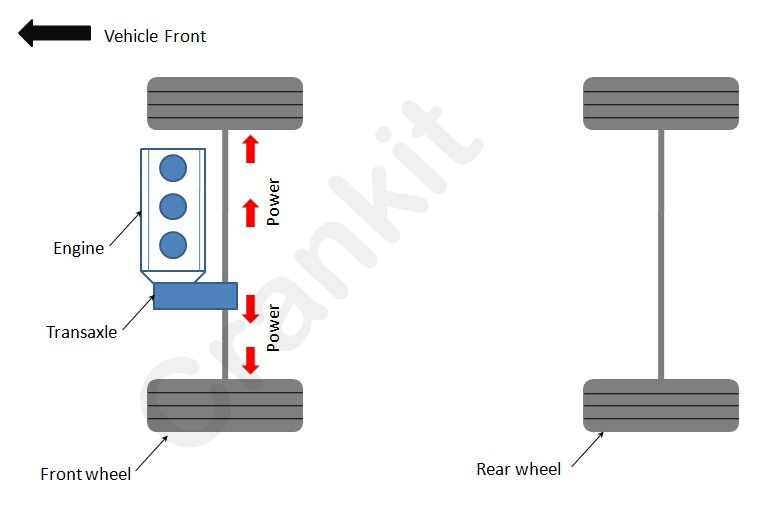

At its core, FWD means that the engine's power is directed to the front wheels, which are responsible for both steering and propulsion. This contrasts with Rear-Wheel Drive (RWD) or All-Wheel Drive (AWD) systems. The major components working together in a FWD system include:

- Engine: The heart of the operation, providing the initial power.

- Transmission/Transaxle: A transaxle combines the functions of a transmission and a differential into a single unit, which is crucial for FWD. It modifies the engine's torque and speed, and splits the power output to the driven wheels.

- Differential: Housed within the transaxle, the differential allows each front wheel to rotate at different speeds. This is essential when turning, as the outside wheel needs to travel a greater distance than the inside wheel.

- Drive shafts (Half-shafts): These connect the transaxle to the front wheels. They transmit the rotational force from the differential to the wheels, causing them to turn. They are designed with constant-velocity (CV) joints to allow for articulation during steering and suspension movement.

- CV Joints (Constant Velocity Joints): Located at both ends of the drive shafts, CV joints allow the drive shaft to transmit power smoothly through varying angles. They are critical for steering and handling. The two common types are fixed joints (near the wheel hub) and plunge joints (near the transaxle).

- Steering System: This system is integrated with the front wheels, allowing the driver to control the direction of the vehicle. Common steering systems include rack-and-pinion, often assisted by hydraulic or electric power steering.

- Suspension System: The front suspension (typically MacPherson strut or double wishbone) absorbs road imperfections and maintains tire contact. It also plays a key role in handling and ride comfort.

Symbols and Diagram Conventions

Understanding the diagram is crucial for effective troubleshooting. Here's a breakdown of common symbols and conventions you might encounter:

- Solid Lines: Generally represent physical connections, such as drive shafts or linkages. Thicker lines often indicate major components.

- Dashed Lines: Can indicate vacuum lines, hydraulic lines (power steering), or electrical wiring. Their thickness might indicate the line's pressure rating or wire gauge.

- Arrows: Show the direction of fluid flow (e.g., power steering fluid) or the transmission of power (e.g., from the transaxle to the wheels).

- Color Coding: Different colors might be used to distinguish different systems. For instance, red might indicate hydraulic lines, blue for coolant, and yellow for electrical. Refer to the diagram's legend for specific color codes.

- Component Icons: Standardized icons are used to represent components like the engine, transaxle, differential, CV joints, etc. Familiarize yourself with these symbols for quick identification.

- Torque Specifications: Often listed near the corresponding bolt or fastener. These values are crucial for proper assembly and preventing damage.

How It Works

The engine generates power through combustion. This power is then transmitted to the transaxle. Within the transaxle, gears are selected to provide the desired torque and speed to the drive shafts. The differential, also housed within the transaxle, splits the power between the two front wheels, allowing them to rotate at different speeds during turns. The drive shafts, equipped with CV joints, then transfer this rotational force to the wheels, causing them to turn and propel the vehicle forward.

The steering system is directly linked to the front wheels. When the driver turns the steering wheel, it actuates a linkage (usually a rack-and-pinion system) that pivots the front wheels, allowing the vehicle to change direction. The front suspension system ensures that the wheels maintain contact with the road, even over uneven surfaces, providing stability and control.

The efficiency of a FWD system is generally considered higher compared to RWD, as less power is lost in the drivetrain (fewer components to transfer the power). However, FWD vehicles can sometimes experience torque steer, a pulling sensation on the steering wheel during hard acceleration, due to unequal drive shaft lengths or suspension geometry issues.

Real-World Use: Basic Troubleshooting Tips

Here are some common FWD issues you might encounter and how to approach them:

- Clicking or Popping Noise While Turning: This is a classic sign of a worn or damaged CV joint. Inspect the CV joint boots for tears or grease leaks. If the boot is damaged, the joint is likely contaminated and needs replacement.

- Vibration During Acceleration: Can be caused by unbalanced wheels, worn tires, or damaged drive shafts. Inspect the tires for uneven wear, and consider having the wheels balanced. Check the drive shafts for any signs of bending or damage.

- Difficulty Shifting Gears: Could indicate issues with the transmission/transaxle, clutch (in manual transmissions), or shift linkage. Start by checking the fluid level in the transaxle. If the fluid is low or contaminated, it could be affecting shifting performance.

- Excessive Play in Steering: Could be due to worn tie rod ends, ball joints, or a loose steering rack. Inspect these components for any signs of wear or damage.

- Uneven Tire Wear: Often indicates suspension alignment issues. Have the alignment checked and adjusted to ensure proper tire wear.

Safety Considerations

Working on FWD systems involves handling components under significant stress and potentially hazardous fluids. Always prioritize safety:

- Proper Lifting and Support: Never work under a vehicle supported only by a jack. Use jack stands rated for the vehicle's weight.

- Disconnect Battery: Before working on any electrical components, disconnect the negative terminal of the battery to prevent accidental shorts.

- Handle CV Joints with Care: Avoid bending or damaging the CV joints during removal and installation.

- Dispose of Fluids Properly: Used transmission fluid, brake fluid, and other automotive fluids are hazardous waste. Dispose of them according to local regulations.

- Wear Safety Glasses: Protect your eyes from flying debris or splashing fluids.

- Use the Right Tools: Using the correct tools for the job is crucial for safety and preventing damage to components.

- Torque to Spec: Always use a torque wrench to tighten bolts and fasteners to the manufacturer's specified torque. Over-tightening can damage components, while under-tightening can lead to loosening and failure.

Specifically, the CV joints are crucial for reliable vehicle operation but require careful handling. Their precise engineering makes them sensitive to impacts and contamination. When removing or installing drive shafts, be gentle and avoid stressing the CV joints beyond their designed range of motion. Similarly, springs in the suspension can release very quickly and need specialist tools to compress before disassembly.

With a solid understanding of these key components and safety protocols, you're well-equipped to tackle basic maintenance and repairs on FWD vehicles. Remember to consult the vehicle's service manual for specific procedures and torque specifications.

Ready to dive deeper? You can download the detailed FWD system diagram here. This diagram provides a visual representation of the system, highlighting key components and their relationships. Use it as a reference guide when diagnosing problems or performing maintenance. Good luck, and stay safe!