What Is Heat Soaking In Cars

Alright, let's dive into heat soaking in cars. It's a phenomenon that affects just about every vehicle on the road, and understanding it can be invaluable whether you're tackling repairs, planning performance modifications, or simply trying to diagnose an unusual issue. This article will break down the 'what,' 'why,' and 'how' of heat soaking, giving you the technical understanding you need without getting lost in jargon.

What is Heat Soaking?

Heat soaking, in the context of an automobile, refers to the gradual accumulation and retention of heat within the engine compartment and surrounding components *after* the engine has been shut off. It's the heat that continues to radiate from the hot engine block, exhaust manifold, catalytic converter, and other engine parts, even when the cooling system isn't actively circulating coolant. Think of it like a cast iron skillet – it stays hot for a long time after you've turned off the burner.

The purpose of understanding heat soaking is multifaceted. It can help you diagnose hard starting issues, prevent vapor lock, optimize fuel delivery, and ultimately, improve the overall performance and longevity of your vehicle. Ignoring heat soaking can lead to premature failure of sensitive components.

Key Specs and Main Parts Affected

Several factors contribute to the severity of heat soaking:

- Ambient Temperature: The hotter the outside air, the more pronounced the heat soaking effect.

- Engine Design: Compact engine bays with poor ventilation exacerbate the issue. Some engine designs inherently trap more heat than others.

- Operating Conditions: Prolonged idling, stop-and-go traffic, and heavy towing put more thermal stress on the engine.

- Cooling System Efficiency: A poorly maintained or inefficient cooling system allows the engine to run hotter, leading to increased heat soaking after shutdown.

The main parts affected by heat soaking include:

- Fuel System Components: Fuel lines, fuel injectors, and fuel pumps can be negatively impacted. Vapor lock, a condition where fuel vaporizes in the lines due to excessive heat, is a classic symptom of heat soaking.

- Electronic Control Unit (ECU): The ECU is relatively robust, but prolonged exposure to high temperatures can shorten its lifespan or cause intermittent malfunctions.

- Sensors: Manifold Absolute Pressure (MAP) sensors, throttle position sensors (TPS), and crankshaft position sensors are all sensitive to heat. Inaccurate readings can result from heat soaking.

- Ignition System Components: Ignition coils and other ignition components can experience reduced performance or premature failure due to excessive heat.

- Wiring Harnesses: The insulation on wires can become brittle and crack under prolonged exposure to high temperatures, leading to shorts and other electrical problems.

- Rubber and Plastic Components: Hoses, vacuum lines, and plastic connectors become brittle and prone to cracking when exposed to excessive heat.

How Heat Soaking Works

When the engine is running, the cooling system (radiator, water pump, thermostat) actively removes heat from the engine block. However, when the engine is switched off, the coolant stops circulating. The heat generated during combustion is still present in the engine components. This heat then begins to radiate outwards, raising the temperature of the surrounding components in the engine bay.

Conduction, convection, and radiation are the three primary modes of heat transfer involved. Conduction is the transfer of heat through direct contact, like the heat transferring from the engine block to the cylinder head. Convection is the transfer of heat through the movement of fluids (in this case, air), such as hot air rising from the engine. Radiation is the transfer of heat through electromagnetic waves, which is how the exhaust manifold heats surrounding components even without direct contact.

The severity of heat soaking depends on the thermal mass of the engine components. The exhaust manifold, being made of cast iron or stainless steel, has a high thermal mass and retains heat for a long time. Aluminum engine blocks tend to dissipate heat faster than cast iron blocks.

Real-World Use – Basic Troubleshooting Tips

Here are some common symptoms and troubleshooting tips related to heat soaking:

Hard Starting After Hot Soak

Symptom: Engine cranks but fails to start easily after sitting for 30-60 minutes after being driven. This is a classic sign of heat soaking.

- Possible Cause: Vapor lock in the fuel lines or injectors. The fuel has vaporized due to excessive heat, making it difficult for the engine to draw in a liquid fuel charge.

- Troubleshooting: Check for fuel leaks. Consider insulating fuel lines. Some mechanics will pour cool water over the fuel rail to see if it helps with restarting. (proceed with caution, do not pour water on electrical components). Also check the fuel pressure regulator for leaks.

Reduced Performance

Symptom: Noticeable decrease in engine power or fuel economy, especially after driving for extended periods in hot weather.

- Possible Cause: Inaccurate sensor readings due to heat soaking. The ECU may be receiving incorrect data about engine temperature, air intake temperature, or other parameters, leading to suboptimal fuel delivery and ignition timing.

- Troubleshooting: Use a scan tool to monitor sensor readings. Check for any DTC (Diagnostic Trouble Code) related to temperature sensors. Examine wiring harnesses for signs of heat damage.

Erratic Idling

Symptom: Unstable or fluctuating idle speed after the engine has reached operating temperature.

- Possible Cause: Heat-related malfunctions of the idle air control (IAC) valve or throttle position sensor (TPS).

- Troubleshooting: Clean the IAC valve. Check the TPS voltage. Inspect vacuum lines for leaks.

Component Failure

Symptom: Premature failure of fuel pumps, ignition coils, or other engine components.

- Possible Cause: Prolonged exposure to excessive heat from heat soaking.

- Troubleshooting: Consider relocating heat-sensitive components to cooler locations. Install heat shields to protect components from radiant heat. Inspect rubber hoses for cracks and replace as needed.

Safety – Highlight Risky Components

Working around a hot engine requires caution. Never touch the exhaust manifold or catalytic converter immediately after the engine has been running. These components can reach extremely high temperatures and cause severe burns. Also, be aware of pressurized fuel lines. Releasing pressure or disconnecting lines when the engine is hot increases the risk of fuel spraying and potential fire. Always allow the engine to cool down before working on the fuel system.

When pouring water for the troubleshooting, ensure the engine is off and avoid electrical components. This prevents electric shock. Disconnect battery ground terminal before doing any electrical work.

Moving Forward

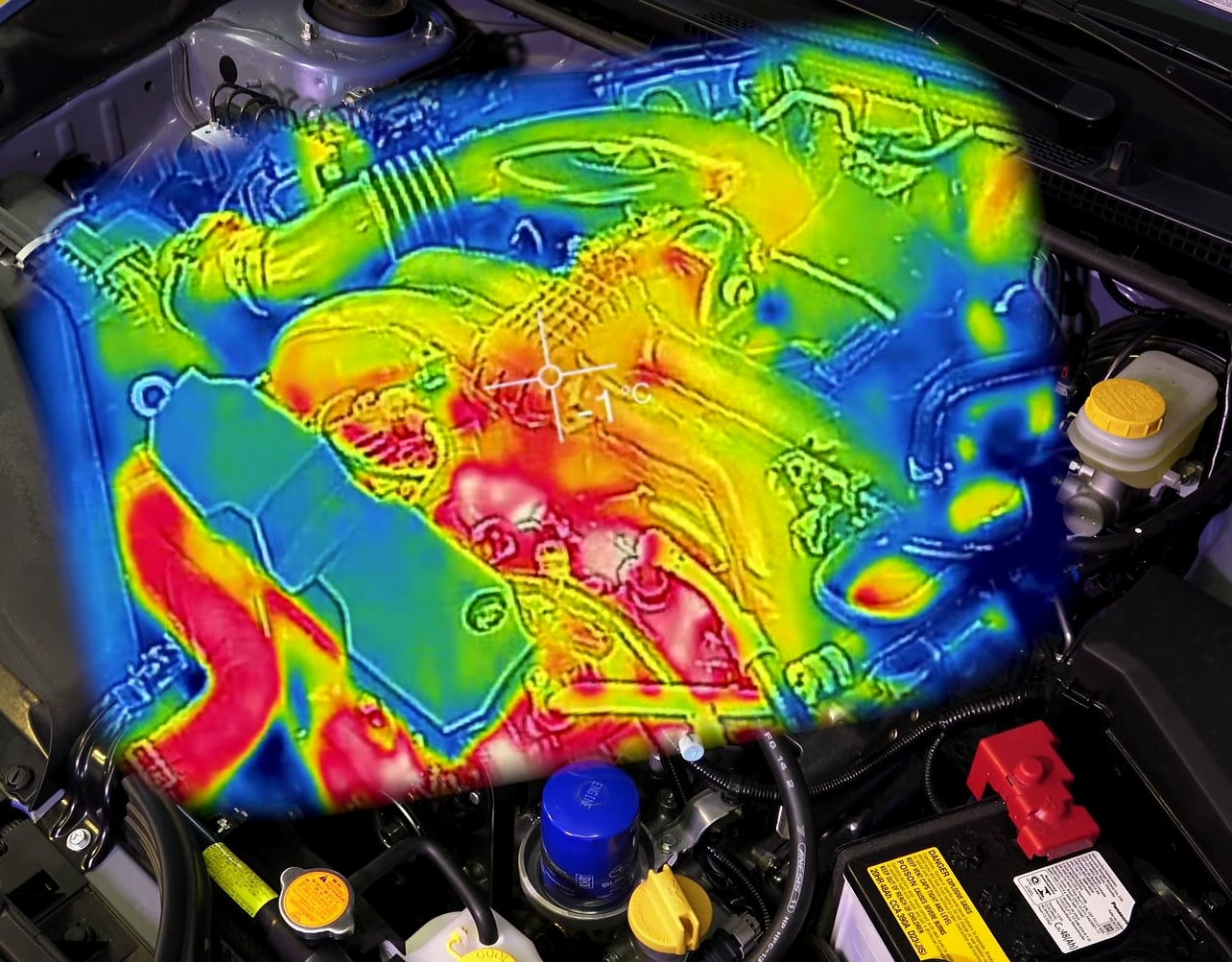

This discussion has covered the key elements of heat soak, but there is always more to learn. If you'd like a more detailed reference, including a diagram highlighting potential heat soak areas and component locations, we have a downloadable file available. It provides a visual aid to further enhance your understanding and troubleshooting capabilities.