What Is Overdrive Gear Used For

Overdrive gears are a crucial component in modern vehicles, contributing significantly to fuel efficiency and reduced engine wear at cruising speeds. Understanding how overdrive works can be invaluable for DIY mechanics and car enthusiasts, especially when diagnosing transmission issues or considering performance modifications. This article provides a detailed look into the function, mechanics, and practical application of overdrive gears.

Purpose of Overdrive

The primary purpose of an overdrive gear is to reduce the engine's revolutions per minute (RPM) at higher vehicle speeds. Without overdrive, the engine would need to spin at a relatively high RPM to maintain a constant highway speed. This high RPM translates to increased fuel consumption, more engine wear and tear, and potentially more noise in the cabin. Overdrive allows the engine to operate at a lower, more efficient RPM for a given vehicle speed. This improves fuel economy, extends engine life, and provides a quieter ride.

Key Specs and Main Parts

Overdrive systems can be found in both manual and automatic transmissions, although the implementation differs slightly. Here's a breakdown of key specifications and components:

- Gear Ratio: Overdrive gears have a gear ratio less than 1:1. This means the output shaft of the transmission spins faster than the input shaft (connected to the engine). For example, a 0.8:1 overdrive ratio means that for every revolution of the input shaft, the output shaft rotates 1.25 times.

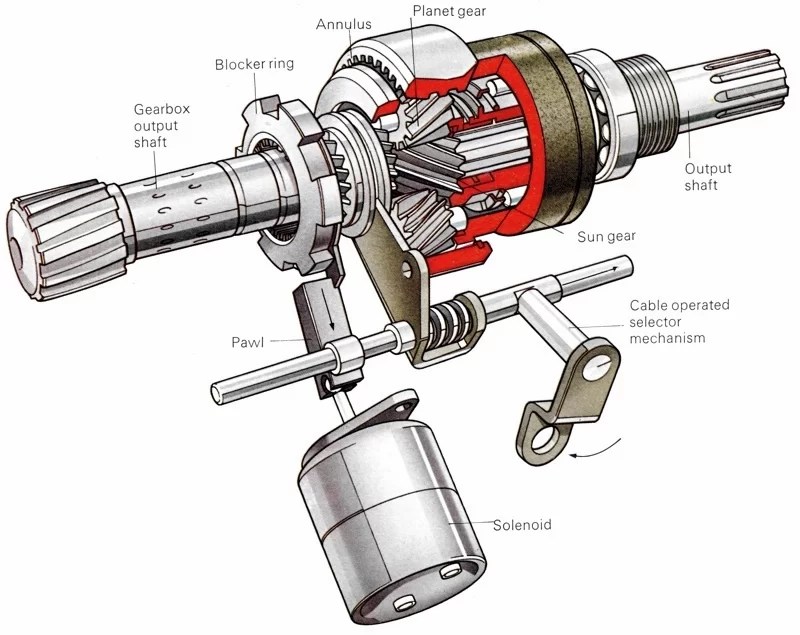

- Planetary Gear Set: Commonly used in automatic transmissions, a planetary gear set allows for multiple gear ratios within a compact space. It typically consists of a sun gear, planet gears, a ring gear, and a carrier. By locking or releasing different elements of the planetary gear set using clutches and bands, different gear ratios can be achieved, including overdrive.

- Clutches and Bands: In automatic transmissions, clutches and bands are hydraulically controlled components that engage and disengage to lock or release specific gears within the planetary gear set. These components are critical to the smooth operation of the overdrive function.

- Solenoids: Electrically controlled valves that direct hydraulic fluid to engage or disengage the clutches and bands in automatic transmissions. These are controlled by the vehicle's computer (ECU/PCM).

- Sensors: Speed sensors (both input and output shaft speeds) are crucial for the transmission control module (TCM) to determine when to engage or disengage overdrive. Throttle position sensors (TPS) are also used to determine engine load.

- Transmission Control Module (TCM): A dedicated computer (or integrated into the ECU/PCM) that controls the automatic transmission's operation, including engaging and disengaging overdrive based on sensor inputs and programmed logic.

How It Works (Automatic Transmission)

In an automatic transmission, the process of engaging overdrive is typically managed by the TCM. Here's a simplified step-by-step explanation:

- Data Acquisition: The TCM receives input from various sensors, including vehicle speed sensors (VSS), throttle position sensor (TPS), and engine RPM.

- Logic Processing: Based on the sensor inputs, the TCM determines whether the vehicle is operating under conditions suitable for overdrive engagement. This usually involves a combination of factors such as reaching a certain speed threshold, having a steady throttle position, and the engine operating within a specific RPM range.

- Solenoid Activation: If the TCM determines that overdrive can be engaged, it sends an electrical signal to the appropriate solenoid.

- Hydraulic Activation: The energized solenoid directs hydraulic fluid to actuate the appropriate clutch or band, locking or releasing the necessary components of the planetary gear set.

- Gear Ratio Change: With the correct clutch or band engaged, the transmission shifts into overdrive, resulting in a lower engine RPM for a given vehicle speed.

How It Works (Manual Transmission)

Manual transmissions with overdrive have a dedicated overdrive gear, usually the highest gear (e.g., 5th or 6th). The driver manually selects this gear when conditions are appropriate for cruising. No computer control is involved; it's purely a mechanical engagement.

Real-World Use & Basic Troubleshooting

Here are some common issues related to overdrive and basic troubleshooting steps:

- Overdrive Not Engaging:

- Check the overdrive switch (if equipped) to ensure it's not disabled.

- Inspect the transmission fluid level and condition. Low or contaminated fluid can cause shifting problems.

- Check for diagnostic trouble codes (DTCs) using an OBD-II scanner. Codes related to solenoids, sensors, or the TCM can indicate a problem.

- If equipped, test the overdrive solenoid using a multimeter to check for proper resistance.

- Erratic Shifting in Overdrive:

- This can be caused by a malfunctioning TPS or VSS. Check these sensors for proper operation.

- Also check the transmission fluid.

- Consider the vehicle's load. If the vehicle is heavily loaded or climbing a steep hill, the overdrive may repeatedly engage and disengage ("hunting"). In these situations, manually disengaging overdrive can improve performance and reduce strain on the transmission.

- "Check Engine" Light with Transmission Issues:

- Immediately scan the vehicle for diagnostic trouble codes. Many transmission-related issues will trigger the "check engine" light.

Safety

Working on automatic transmissions can be dangerous due to the presence of high-pressure hydraulic fluid and electrical components. Here are some important safety precautions:

- Hydraulic Fluid: Be extremely careful when working with hydraulic fluid. It can be very hot and under high pressure, posing a burn hazard. Allow the system to cool down before opening any lines or components. Always wear safety glasses.

- Electrical Components: Disconnect the battery before working on any electrical components of the transmission, such as solenoids or sensors.

- Jacking the Vehicle: Always use jack stands when working under a vehicle supported by a jack. Never rely solely on the jack.

- Transmission Weight: Transmissions are heavy. Use a transmission jack when removing or installing a transmission.

Conclusion

Understanding overdrive systems is essential for maintaining and troubleshooting modern vehicles. By grasping the function of the overdrive gear, diagnosing potential problems, and applying the correct troubleshooting techniques, experienced DIYers can save money on repairs and enhance their knowledge of automotive technology. Armed with this information, you're better equipped to understand the inner workings of your vehicle's transmission and address potential issues effectively.

Remember, we have a detailed diagram of a typical overdrive system available for download. This diagram includes all the key components and their interconnections, providing a valuable resource for your repairs or learning. We hope this article has given you the knowledge you need.