What Is Paddle Shift In Cars

Understanding Paddle Shifters: A Technical Deep Dive

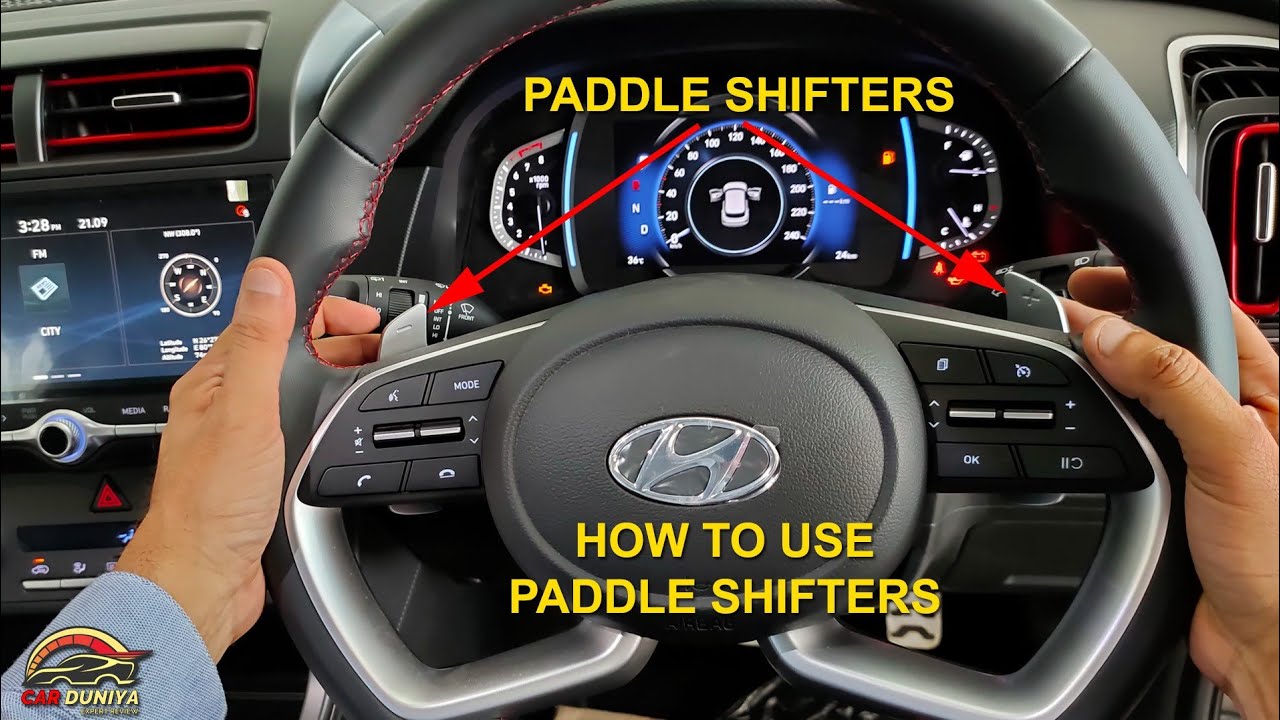

Welcome, fellow gearheads! You've probably seen those little levers tucked behind the steering wheel in modern cars – the paddle shifters. They look cool, but what do they actually do, and how do they work? This article is your comprehensive guide to understanding paddle shifters, from their purpose to troubleshooting common issues. Think of this as the information you'd get from a seasoned mechanic, explained in a way that makes sense for an experienced DIYer like yourself.

Purpose and Why Understanding Matters

The primary purpose of paddle shifters is to provide the driver with manual control over an automatic transmission or a dual-clutch transmission (DCT) without the need for a traditional clutch pedal and gear lever. This offers a blend of convenience and performance, allowing for quicker gear changes and more engaging driving dynamics, especially in sporty or performance-oriented vehicles. Understanding paddle shifters matters for several reasons:

- Performance Enhancement: Using paddle shifters effectively allows you to maximize engine power and torque, leading to quicker acceleration and improved cornering.

- Troubleshooting: If your paddle shifters aren't working correctly, understanding their operation is crucial for diagnosing the problem.

- Modifications & Upgrades: You might be considering adding paddle shifters to a car that didn't originally have them, or upgrading existing ones. Knowledge is key!

- Preventative Maintenance: Catching small issues early can prevent bigger, more expensive problems down the road.

Key Specs and Main Parts

Let's break down the essential components of a paddle shift system:

- Paddles: These are the physical levers located behind the steering wheel. Typically, there's a "+" paddle for upshifting and a "-" paddle for downshifting. Material can range from plastic to metal (aluminum, magnesium) depending on the car's trim and intended usage.

- Switches/Sensors: When you pull a paddle, it activates a switch or sensor. These are usually hall-effect sensors or micro-switches. Hall-effect sensors are preferred because of their increased reliability and longer lifespan.

- Wiring Harness: The signal from the switches/sensors is transmitted through a wiring harness to the transmission control unit (TCU) or engine control unit (ECU). Pay attention to the integrity of this harness. Damaged wiring can be a major source of issues.

- Transmission Control Unit (TCU) / Engine Control Unit (ECU): The TCU (or ECU in some cases) is the "brain" of the operation. It receives the signal from the paddles, interprets it, and then sends commands to the transmission to execute the gear change.

- Solenoids: Inside the transmission, solenoids are electronically controlled valves that direct hydraulic fluid to engage and disengage different gear sets. The TCU controls these solenoids based on the paddle shifter input.

- Hydraulic System (Automatic Transmissions): Automatic transmissions utilize hydraulic pressure to engage clutches and bands for gear selection. The solenoids, controlled by the TCU based on paddle input, manage this hydraulic pressure.

- Actuators (DCTs): Dual-clutch transmissions use electromechanical or electrohydraulic actuators to engage and disengage the clutches and shift forks. These actuators are controlled by the TCU.

How It Works

The operation of a paddle shift system can be described in a few key steps:

- Driver Input: You pull either the "+" or "-" paddle.

- Signal Transmission: The activated switch/sensor sends a signal through the wiring harness to the TCU/ECU.

- Signal Interpretation: The TCU/ECU receives the signal and determines the appropriate action based on factors like current gear, engine speed (RPM), vehicle speed, and throttle position. Modern systems often incorporate "shift logic" that prevents downshifts that would over-rev the engine.

- Transmission Control: The TCU/ECU sends a command to the appropriate solenoids (automatic transmission) or actuators (DCT) within the transmission.

- Gear Change: The solenoids/actuators engage or disengage the necessary clutches/bands or shift forks to execute the gear change.

The TCU/ECU is constantly monitoring various parameters to ensure smooth and safe gear changes. For example, it might briefly cut ignition timing during an upshift to reduce torque and prevent harshness. Downshifts are often accompanied by "rev-matching," where the TCU briefly blips the throttle to increase engine speed and match it to the new gear, resulting in a smoother transition and reduced stress on the drivetrain.

Real-World Use – Basic Troubleshooting Tips

Here are a few common issues and how you might diagnose them:

- Paddles Not Responding: This could be due to a faulty switch/sensor in the paddle itself, a broken wire in the harness, or a problem with the TCU/ECU. Start by checking the connections to the paddles and the wiring harness for any damage. Use a multimeter to test the continuity of the wiring and the functionality of the switches/sensors. A scan tool can also read diagnostic trouble codes (DTCs) that might point to a specific issue.

- Delayed or Jerky Shifts: This could be caused by low transmission fluid, worn-out solenoids (automatic transmission), or failing actuators (DCT). Check the transmission fluid level and condition. If the fluid is dark or smells burnt, it's time for a fluid change. A scan tool can often test the functionality of the solenoids/actuators.

- Inconsistent Performance: Sometimes the paddles work, sometimes they don't. This could indicate a loose connection, intermittent wiring issue, or a failing sensor. Carefully inspect the wiring and connections for any signs of corrosion or damage.

Important: Always consult your vehicle's repair manual for specific troubleshooting procedures and diagnostic information. Remember to disconnect the battery before working on any electrical components.

Safety – Highlight Risky Components

Working on a paddle shift system involves some potential safety hazards:

- Electrical System: The wiring harness and TCU/ECU are part of the vehicle's electrical system. Always disconnect the battery before working on any electrical components to prevent electrical shock.

- Airbag System: The steering wheel often houses the airbag. Mishandling the airbag system can result in accidental deployment, which can cause serious injury. Consult your vehicle's repair manual for proper airbag disabling procedures before removing the steering wheel.

- Transmission Fluid: Transmission fluid can be hot and under pressure. Allow the transmission to cool down before checking or changing the fluid. Wear gloves and eye protection to prevent burns and irritation.

Never attempt to modify or tamper with the airbag system without proper training and equipment.

If you are unsure about any aspect of the repair or diagnosis, consult a qualified mechanic.

By understanding the components, operation, and potential issues of paddle shifters, you're well-equipped to troubleshoot problems, perform maintenance, and even consider performance upgrades. Remember to prioritize safety and always consult your vehicle's repair manual for specific instructions.