What Is Paddle Shifting In Cars

Paddle shifters have become increasingly common in modern vehicles, from performance cars to everyday sedans. Understanding how they work empowers you to troubleshoot issues, appreciate the engineering, and even explore modifications down the line. This article delves into the mechanics and electronics behind paddle shifting, providing a technical overview suitable for experienced DIYers and car enthusiasts.

Purpose of Understanding Paddle Shifting

A solid understanding of paddle shifting is crucial for several reasons:

- Diagnostics and Repairs: When encountering issues with your paddle shifters, knowing the underlying system allows you to pinpoint the source of the problem, whether it's a faulty switch, wiring issue, or a problem within the transmission control unit (TCU).

- Performance Enhancement: Some DIYers explore modifying the shift mapping or responsiveness of their paddle shifters. This requires a deep understanding of the system's operation.

- Informed Modifications: Before making any modifications to your vehicle's transmission system, including the paddle shifters, it's vital to understand how the existing system functions to avoid unintended consequences.

- General Car Knowledge: Understanding paddle shifting adds to your overall automotive knowledge, enabling you to better appreciate the technology behind modern vehicles.

Key Specs and Main Parts

The paddle shifting system, at its core, is an interface between the driver and the automatic or automated manual transmission. The key components include:

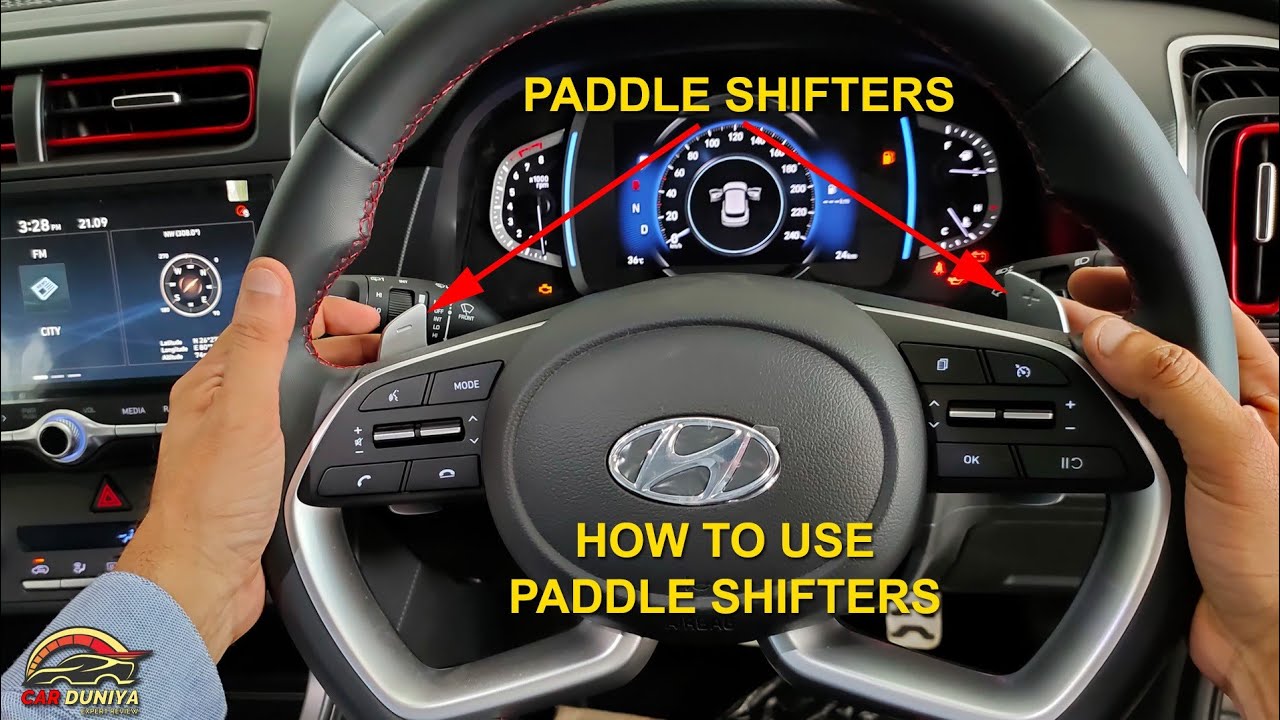

- Paddles: These are the physical levers located behind the steering wheel that the driver uses to initiate gear changes. Typically, one paddle is for upshifting (+) and the other for downshifting (-).

- Switches/Sensors: When a paddle is pulled, it activates a switch or sensor. These sensors are often Hall-effect sensors, which detect the presence of a magnetic field.

- Wiring Harness: The electrical signals from the paddle switches are transmitted to the vehicle's electronic control units (ECUs) via a wiring harness.

- Clock Spring/Rotary Coupler: This component allows the steering wheel to rotate while maintaining a continuous electrical connection to the vehicle's electrical system. It's a crucial component in connecting the paddle shifters to the rest of the car's electronics.

- Transmission Control Unit (TCU): The TCU is a dedicated computer that controls the automatic or automated manual transmission. It receives the signals from the paddle shifters and translates them into commands for the transmission.

- Electronic Control Unit (ECU): In some vehicles, the engine control unit (ECU) is also involved in the paddle shifting process, especially for throttle blipping during downshifts or for managing engine torque during gear changes.

- Transmission: The transmission itself, which could be a traditional automatic transmission with a torque converter or an automated manual transmission (AMT) with clutches controlled electronically.

How It Works

The paddle shifting system operates through a series of electrical and electronic interactions:

- Paddle Activation: When the driver pulls a paddle, it activates a switch or sensor. This sensor sends a low-voltage electrical signal.

- Signal Transmission: The signal travels through the wiring harness and the clock spring to the vehicle's electronic control units (ECUs).

- TCU Interpretation: The TCU receives the signal and interprets it as a request for an upshift or downshift.

- Transmission Control: Based on the driver's request, the current gear, engine speed, and other parameters, the TCU commands the transmission to execute the shift. This involves actuating solenoids that control the flow of hydraulic fluid within the transmission to engage and disengage different gear sets. In an automated manual transmission, the TCU controls the clutches and gear selection directly.

- Feedback and Confirmation: The TCU monitors the transmission's operation and confirms that the shift has been successfully completed.

Modern systems often incorporate sophisticated algorithms to ensure smooth and safe shifts. For example, the TCU might delay a downshift if the engine speed is too high, preventing over-revving. It may also perform throttle blipping during downshifts to match engine speed to the transmission speed, resulting in smoother gear changes.

Real-World Use – Basic Troubleshooting Tips

Here are some common problems you might encounter and some initial troubleshooting steps:

- Paddles Not Responding:

- Check the fuses related to the transmission control system. A blown fuse can disable the paddle shifters.

- Inspect the wiring harness and connectors for damage or corrosion, especially around the steering column and inside the steering wheel.

- Use a multimeter to test the continuity of the paddle switches. If a switch is faulty, it may need to be replaced.

- If you have access to a diagnostic scan tool, check for trouble codes related to the transmission control system or the paddle shifters themselves.

- Delayed or Jerky Shifts:

- Ensure that the transmission fluid is at the correct level and in good condition. Low or contaminated fluid can affect shift quality.

- Check for trouble codes related to the transmission. These codes can provide clues about potential problems with the transmission itself.

- In rare cases, the TCU itself might be malfunctioning. This is more difficult to diagnose and may require specialized equipment.

Important Note: Many modern vehicles have complex electronic systems. If you're not comfortable working with electrical systems, it's best to consult a qualified mechanic.

Safety – Highlight Risky Components

Working on the electrical system of a car always carries risks. Here are some specific areas to be cautious of:

- Airbag System: The steering wheel houses the airbag module. Never work on the steering wheel without first disconnecting the battery and taking the necessary precautions to prevent accidental airbag deployment. Refer to your vehicle's service manual for specific instructions.

- Clock Spring: The clock spring is a delicate component. Improper handling can damage it, leading to electrical issues and potentially disabling the airbag.

- Electrical System: Always disconnect the battery before working on any part of the electrical system to prevent electrical shock.

- Transmission: When working on the transmission, be aware that it contains pressurized hydraulic fluid. Avoid disconnecting any lines or components without first relieving the pressure.

Incorrectly installing or modifying the paddle shifters could lead to unintended consequences, such as erratic shifting behavior or even damage to the transmission. Always consult your vehicle's service manual and follow the manufacturer's instructions carefully.

This article has provided a detailed overview of paddle shifting in cars. We have a detailed diagram available that visually represents the system, including the wiring and connections. Understanding the specifics of your car's paddle shifting system will allow you to better appreciate its function and efficiently troubleshoot any problems that might arise.