What Is The Abs Light On A Car

So, you've got that amber ABS light staring back at you from the dashboard. Don't panic! It's telling you something, and understanding what that is can save you a ton of money and keep you safe. This article is designed to give you a solid understanding of your Anti-lock Braking System (ABS), what that light means, and how to approach troubleshooting. We'll skip the jargon where we can, but we'll cover the important technical bits too, so you can talk the talk (and maybe even fix the problem yourself!).

Purpose of Understanding the ABS Light & System

Why bother diving into the ABS? Well, a malfunctioning ABS can compromise your braking performance, especially in slippery conditions. That ABS light isn't just an annoyance; it's a warning that your car might not stop as effectively as it should. Understanding the system allows you to:

- Diagnose Issues: Identify potential problems and pinpoint the faulty component.

- Perform Basic Repairs: Address simpler issues like sensor cleaning or wiring repairs.

- Communicate Effectively: Explain the problem clearly to a mechanic if you can't fix it yourself.

- Make Informed Decisions: Determine if a repair is urgent or can wait.

- Enhance Safety: Ensure your braking system is functioning optimally.

Having a solid grasp of the ABS also empowers you to modify your vehicle safely. For instance, when upgrading brakes or suspension, understanding how these changes affect the ABS is crucial. Ultimately, understanding the ABS is about safety and saving money.

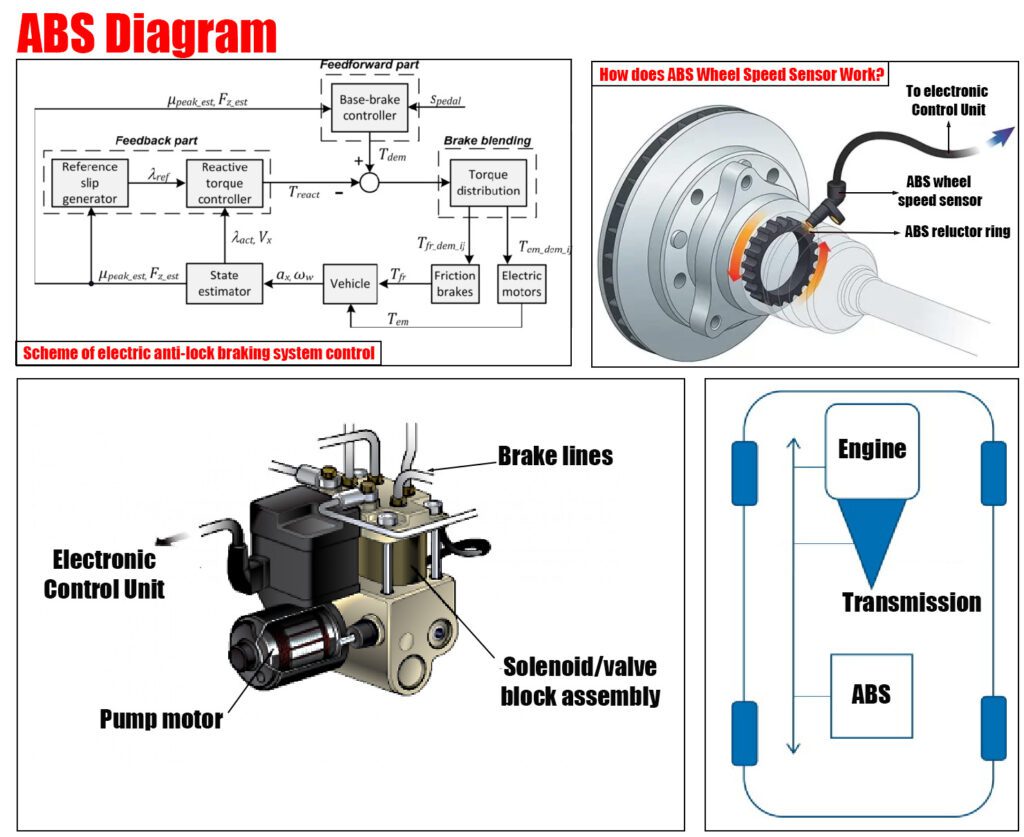

Key Specs and Main Parts of the ABS

The ABS is a complex system, but it boils down to these core components:

- Wheel Speed Sensors (WSS): These are the eyes of the ABS. They constantly monitor the rotational speed of each wheel. They typically use a magnetic pulse ring (reluctor ring) and a sensor that detects the changes in magnetic field as the teeth pass by.

- ABS Control Module (ECU): The brain of the system. It receives data from the wheel speed sensors and determines if a wheel is about to lock up. It contains sophisticated algorithms that interpret sensor data and control the hydraulic modulator.

- Hydraulic Modulator (HCU): The muscles of the system. It contains a series of valves and pumps that precisely control the brake pressure applied to each wheel. It's capable of rapidly increasing, decreasing, or holding brake pressure independently for each wheel circuit.

- Brake Lines: The arteries that carry brake fluid to the calipers. Proper bleeding and inspection are critical to ABS performance.

- Brake Calipers: These house the brake pads and clamp them against the rotors to slow the wheels.

- ABS Pump/Motor: Helps in maintaining pressure in the HCU, and recirculates fluid for pressure modulation.

Key specifications to consider when working on your ABS include:

- Sensor Resistance: Ohm readings of the WSS can indicate if the sensor is functional.

- Fluid Type: Using the wrong brake fluid (e.g., DOT 3 instead of DOT 4) can damage the ABS.

- Brake Line Pressure: Knowing the expected pressure in the system is important for diagnosis.

ABS System Symbols and Diagrams Explained

ABS diagrams aren't as intimidating as they look. Here's how to decipher them:

- Solid Lines: Typically represent hydraulic lines carrying brake fluid.

- Dashed Lines: Usually indicate electrical wiring and signal paths.

- Colors: Color coding varies by manufacturer, but often specific colors are assigned to particular sensor wires or hydraulic circuits. Refer to your vehicle's specific wiring diagram for color assignments.

- Icons: Standard icons represent components like sensors, valves, pumps, and the ECU. Look for the key at the bottom of the diagram to understand these symbols.

A block diagram of a typical ABS system might show the ECU connected to each WSS. The ECU then connects to the HCU. The HCU then connects to each brake caliper circuit.

How the ABS Works: A Breakdown

The ABS works on the principle of preventing wheel lockup during braking. Here's the process:

- Monitoring: The wheel speed sensors constantly send data to the ABS control module (ECU).

- Detection: If the ECU detects that a wheel is slowing down much faster than the others (impending lockup), it activates. This is based on rate of deceleration and comparison of speeds between the wheels.

- Modulation: The ABS modulates brake pressure to that wheel. This typically involves reducing pressure momentarily to allow the wheel to regain traction.

- Cycling: The ABS rapidly cycles the brake pressure (increasing, decreasing, holding) multiple times per second. This allows the driver to maintain steering control while still braking effectively. You’ll feel this as a pulsing sensation in the brake pedal.

This process is repeated for each wheel independently, ensuring maximum braking performance and stability.

Real-World Use: Basic Troubleshooting Tips for ABS

The ABS light is on, now what? Here are some basic troubleshooting steps:

- Visual Inspection: Check the wheel speed sensors for damage or loose connections. Look for cuts or abrasions in the wiring. Ensure the reluctor rings are clean and free of debris.

- Sensor Testing: Use a multimeter to check the resistance of the wheel speed sensors. Compare the readings to the manufacturer's specifications.

- Code Reading: Use an OBD-II scanner with ABS capability to retrieve diagnostic trouble codes (DTCs). These codes will provide clues about the specific problem area.

- Brake Fluid Level: Low brake fluid can trigger the ABS light. Check the reservoir and top it off if necessary.

- Fuse Check: Inspect the ABS fuse. A blown fuse can disable the entire system.

If you find a trouble code for a specific wheel speed sensor, a common issue is a dirty sensor or reluctor ring. Try cleaning these components before replacing the sensor. Sometimes, debris can interfere with the sensor's ability to read the wheel speed accurately.

Safety Considerations: Risky ABS Components

Working with the ABS involves certain risks:

- High Pressure: The hydraulic modulator contains high-pressure brake fluid. Depressurize the system before disconnecting any hydraulic lines. Always consult your vehicle's service manual for the correct depressurization procedure.

- Electronic Components: Be careful when working with the ABS control module. Static electricity can damage sensitive electronic components. Use an anti-static wrist strap.

- Brake Fluid: Brake fluid is corrosive. Avoid skin contact and protect your eyes. Clean up any spills immediately.

- Improper Bleeding: After working on the hydraulic system, properly bleeding the brakes is crucial. Air in the system can severely compromise braking performance and ABS functionality. Some vehicles require specific ABS bleeding procedures using a scan tool.

It's worth reiterating: consult your vehicle's specific service manual before performing any ABS repairs. The manual contains critical safety information and specific procedures for your vehicle model.

We have a generic ABS system diagram available for download to help you visualize the components and their connections. Feel free to grab it for reference. We hope this article has helped you understand the basics of your car's ABS system. With this knowledge, you can tackle simple repairs, diagnose problems effectively, and ensure your car's braking system is always in top condition.