What Is The Cvt In A Nissan

Let's dive into the Continuously Variable Transmission (CVT) found in many Nissan vehicles. Understanding how this transmission works, its key components, and potential issues will empower you to perform basic troubleshooting, interpret diagnostic codes, and even tackle some repairs yourself. We'll break down the technical jargon and provide practical insights for the experienced DIYer.

Purpose: Why Understanding Your Nissan CVT Matters

Why bother learning about your Nissan's CVT? The most obvious reason is repair and maintenance. When your CVT starts acting up, knowing the symptoms, understanding the diagnostic codes, and being able to identify potential problem areas can save you a significant amount of money. Instead of blindly relying on a mechanic, you can approach the issue with informed questions and potentially perform some repairs yourself.

Furthermore, this knowledge can be invaluable for performance modifications (although CVT tuning is a delicate art and often best left to professionals). Understanding the limitations of your CVT will prevent you from pushing it beyond its design limits and potentially causing catastrophic failure. Finally, simply understanding how your car works is satisfying and empowering. It allows you to be a more informed consumer and a more confident driver.

And, for those of you doing a swap or retrofit, understanding the CVT's operation and control systems is absolutely critical.

Key Specs and Main Parts of a Nissan CVT

Nissan uses CVTs from various manufacturers, primarily JATCO. Here are some of the key components common across most Nissan CVTs:

- Torque Converter: This fluid coupling transmits engine torque to the CVT. It allows the engine to idle while the car is stopped and provides torque multiplication at low speeds.

- Forward/Reverse Clutch Pack: Selects the direction of travel (forward or reverse).

- Primary Pulley (Input Pulley): Connected to the engine via the torque converter. Its effective diameter is adjusted hydraulically.

- Secondary Pulley (Output Pulley): Connected to the differential and drives the wheels. Its effective diameter is also adjusted hydraulically.

- Steel Belt or Chain: The heart of the CVT. This belt (or chain) connects the primary and secondary pulleys. Its ability to transfer power while conforming to varying pulley diameters is what makes the CVT unique.

- Hydraulic Control System: A complex system of valves, solenoids, and sensors that regulates the pressure applied to the pulleys, controlling the gear ratio.

- Transmission Control Module (TCM): The "brain" of the CVT. It receives inputs from various sensors (vehicle speed, engine speed, throttle position, etc.) and uses this information to control the hydraulic control system.

- Oil Pump: Provides hydraulic pressure to the entire system.

- CVT Fluid: A specialized fluid designed to withstand the high pressures and temperatures within the CVT. It also provides lubrication and cooling. Using the correct fluid is crucial for CVT longevity.

Key specs to be aware of include the fluid type (Nissan NS-2, NS-3, or equivalent are common – check your owner’s manual!), torque capacity (important if you’re considering engine modifications), and the overall gear ratio range.

Symbols and Diagram Conventions

Understanding schematic diagrams is crucial for effective troubleshooting. Here are some common conventions:

- Solid Lines: Typically represent hydraulic lines carrying CVT fluid.

- Dashed Lines: Often represent electrical wiring.

- Different Colors: Colors are frequently used to differentiate between different hydraulic circuits or electrical signals. The legend will usually identify what each color represents (e.g., red for high-pressure, blue for control pressure).

- Circles: Often represent hydraulic actuators, such as pistons within the pulley assemblies.

- Squares/Rectangles: Can represent valves, solenoids, or electronic components.

- Ground Symbols: Indicate electrical grounding points.

- Arrows: Indicate the direction of fluid flow or electrical signal flow.

The schematic you download should include a detailed key explaining all the symbols used.

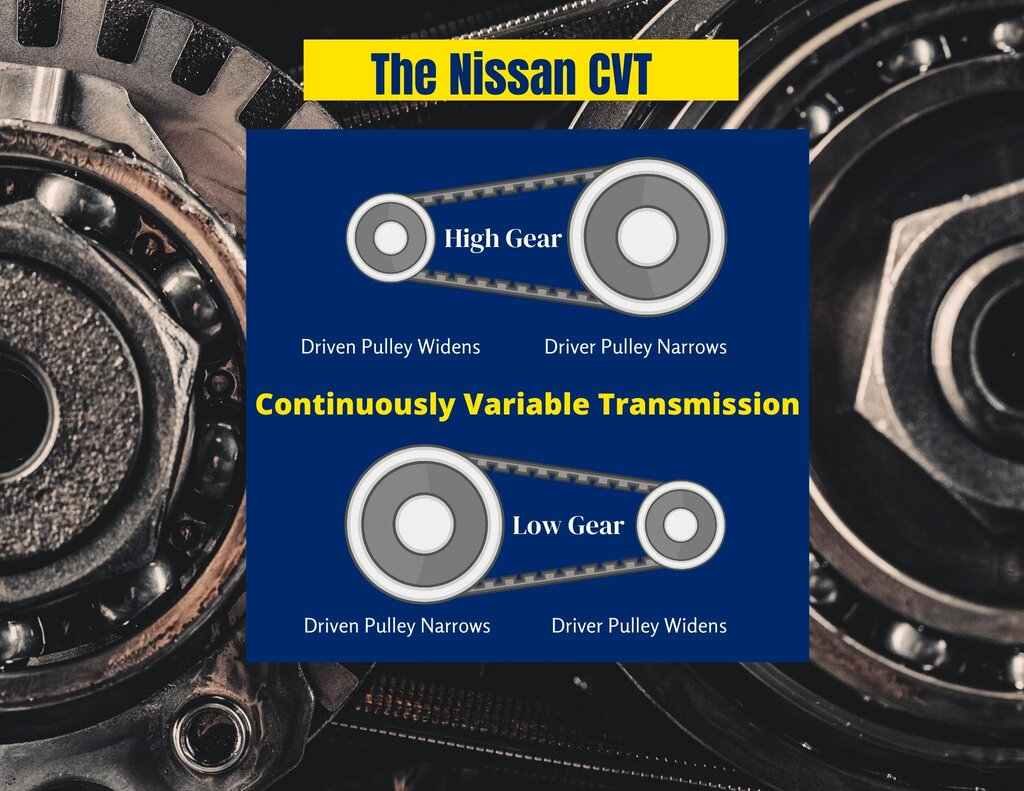

How a Nissan CVT Works

The magic of the CVT lies in its ability to provide a continuously variable gear ratio. Unlike traditional automatic transmissions with fixed gear steps, the CVT can seamlessly adjust the ratio to optimize engine performance and fuel efficiency.

Here’s a simplified explanation:

- The engine's torque is transmitted to the primary pulley via the torque converter.

- The TCM monitors various sensor inputs and determines the optimal gear ratio.

- The TCM controls the hydraulic control system, which adjusts the pressure applied to the primary and secondary pulleys.

- Increasing the pressure on one pulley causes its effective diameter to increase, while simultaneously decreasing the diameter of the other pulley.

- This change in diameter alters the gear ratio between the pulleys.

- The steel belt (or chain) transmits power from the primary pulley to the secondary pulley.

- The secondary pulley transmits power to the differential, which drives the wheels.

For example, during acceleration, the CVT will select a low gear ratio (small diameter on the primary pulley, large diameter on the secondary pulley) to provide maximum torque multiplication. At cruising speed, the CVT will select a high gear ratio (large diameter on the primary pulley, small diameter on the secondary pulley) to improve fuel efficiency.

Real-World Use: Basic Troubleshooting Tips

Here are some common CVT problems and troubleshooting tips:

- Slipping or Hesitation: Could indicate low CVT fluid, contaminated fluid, worn belt/chain, or a failing hydraulic control system. Check the fluid level and condition first.

- Jerky Acceleration: Might be caused by a malfunctioning solenoid or valve in the hydraulic control system. Scan for diagnostic trouble codes (DTCs).

- Whining Noise: Could indicate a failing oil pump or low fluid level.

- Transmission Overheating: Often caused by low fluid, a clogged cooler, or excessive strain on the transmission.

- Diagnostic Trouble Codes (DTCs): Use an OBD-II scanner to retrieve DTCs. These codes provide valuable clues about the source of the problem. Research the specific code to understand its possible causes.

Important: Always use the correct CVT fluid. Using the wrong fluid can damage the CVT. Consider a CVT cooler if you frequently tow or drive in hot conditions.

Safety Considerations

Working on a CVT can be dangerous if you don't take proper precautions. Here are some critical safety considerations:

- High Pressure: The hydraulic system operates at high pressure. Relieve pressure before disconnecting any lines.

- Hot Fluid: CVT fluid can be extremely hot. Allow the transmission to cool down before draining the fluid.

- Electrical Hazards: Disconnect the battery before working on any electrical components.

- Support the Vehicle Properly: Always use jack stands when working under a vehicle.

- Wear Safety Glasses and Gloves: Protect your eyes and hands from fluid and debris.

The hydraulic accumulator (if present) can store significant pressure even when the vehicle is off. Improper handling can lead to serious injury. Consult a service manual for specific procedures on relieving pressure safely.

The CVT valve body contains many small, precision parts. Disassembly should only be attempted with the proper tools and a clean workspace. Loss of even one small check ball can render the transmission inoperable.

Remember, if you're not comfortable performing a repair, it's always best to consult a qualified technician.

We have a detailed schematic diagram of a typical Nissan CVT available for download. This diagram will provide you with a more in-depth understanding of the CVT's internal components and how they interact. This is an invaluable aid for diagnosis and repair.