What Is The Transmission In A Car

Let's dive into the heart of your car's drivetrain: the transmission. This isn't just about knowing where the shift lever is. Understanding how the transmission functions is crucial for diagnosing problems, performing maintenance, and even planning modifications. Whether you're troubleshooting a rough shift or contemplating a transmission swap, a solid grasp of its inner workings is invaluable. Think of this as leveling up your DIY car knowledge.

Purpose of the Transmission

The internal combustion engine (ICE) that powers most cars produces power most efficiently within a relatively narrow band of RPMs (revolutions per minute). The transmission's primary job is to translate this engine output, providing the necessary torque and speed to the wheels, regardless of vehicle speed. Without a transmission, your car would either stall at low speeds or scream at redline before reaching a decent cruising velocity.

In essence, the transmission acts as a torque multiplier at low speeds, giving you the grunt needed to accelerate from a standstill. At higher speeds, it shifts to higher gears, reducing engine RPMs for fuel efficiency and quieter operation. Think of it like riding a bicycle – you use lower gears to climb hills (more torque), and higher gears to cruise on flat ground (more speed with less effort).

Key Specs and Main Parts

Transmissions come in two main flavors: manual and automatic. While the operating principles are similar, the internal components and control mechanisms differ significantly.

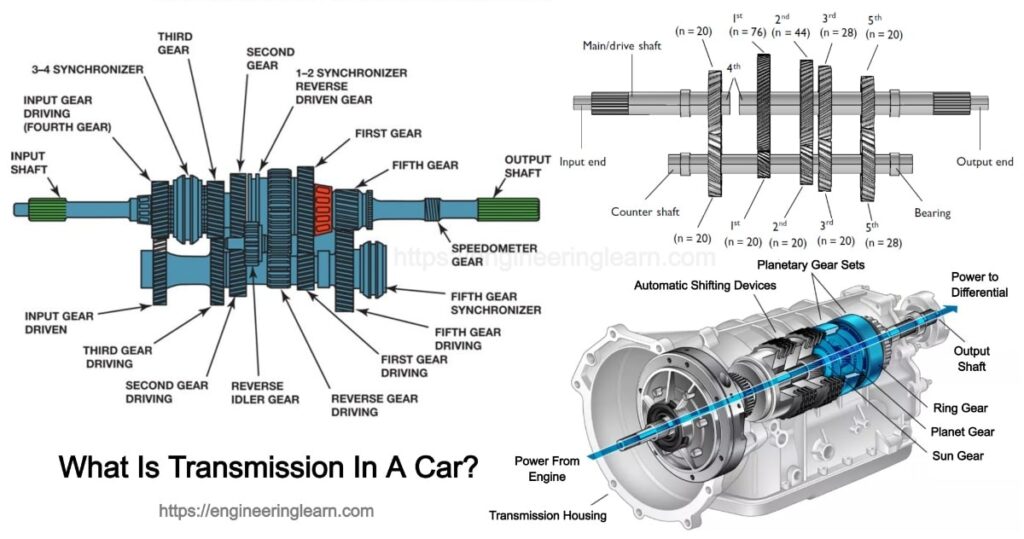

Manual Transmission

A manual transmission relies on the driver to select gears using a clutch and shift lever. Key components include:

- Input Shaft: Connected to the engine's flywheel/clutch assembly. It receives the engine's rotational force.

- Output Shaft: Delivers power to the driveshaft and ultimately the wheels.

- Gears: A series of meshing gears with different ratios, providing various speed and torque combinations.

- Synchronizers (Synchros): These are crucial for smooth shifting. They match the speeds of the gears you're trying to engage, preventing grinding. Bad synchros lead to crunchy shifts.

- Shift Forks and Rails: These move the synchronizers to engage the desired gear.

- Clutch: This mechanism disengages the engine from the transmission, allowing you to change gears without damaging the engine or transmission.

Automatic Transmission

An automatic transmission handles gear changes automatically, using a complex system of hydraulics, electronics, and planetary gearsets. Key components include:

- Torque Converter: This replaces the clutch found in manual transmissions. It's a fluid coupling that allows the engine to keep running even when the wheels are stopped, and it also provides some torque multiplication.

- Planetary Gearsets: These are complex arrangements of gears that provide different gear ratios.

- Valve Body: The hydraulic control center of the transmission. It directs fluid pressure to engage different clutches and bands, controlling gear selection.

- Clutches and Bands: These engage and disengage planetary gearsets to achieve different gear ratios.

- Transmission Control Module (TCM): This electronic brain monitors various sensors and controls the valve body, determining when to shift gears.

- Oil Pump: Provides hydraulic pressure to operate the transmission.

How It Works

Manual Transmission Operation

When you press the clutch pedal, you disconnect the engine from the transmission. You then move the shift lever, which moves the shift forks to engage the desired gear. The synchros ensure a smooth engagement by matching the speeds of the gears. Releasing the clutch re-engages the engine, and power is transferred through the selected gearset to the output shaft and ultimately to the wheels. Different gear ratios provide different levels of torque and speed.

Automatic Transmission Operation

The torque converter allows the engine to spin independently of the transmission at idle. As engine RPMs increase, the torque converter transmits power to the transmission. The TCM monitors vehicle speed, engine load, and throttle position, and then signals the valve body to direct hydraulic fluid to the appropriate clutches and bands, engaging the correct planetary gearset for the desired gear. This process happens automatically, without driver intervention (except for selecting drive, reverse, etc.).

Real-World Use – Basic Troubleshooting Tips

Here are some common transmission issues and possible causes:

- Rough Shifting (Manual): Could be worn synchros, a misadjusted clutch, or low transmission fluid.

- Grinding Gears (Manual): Almost always indicates worn synchros.

- Slipping Clutch (Manual): The engine RPMs increase without a corresponding increase in vehicle speed. Indicates a worn clutch.

- Erratic Shifting (Automatic): Could be low transmission fluid, a faulty TCM, or problems with the valve body.

- Delayed Engagement (Automatic): The transmission takes a long time to engage when shifting into drive or reverse. Could be low fluid, a failing torque converter, or internal damage.

- Transmission Fluid Leaks: Check for leaks around the pan gasket, seals, and cooler lines. Low fluid can cause serious damage.

Important Note: Before attempting any transmission repair, always check the fluid level and condition. Dark, burnt-smelling fluid is a sign of serious problems. Changing the fluid regularly can help prevent many issues.

Safety – Highlight Risky Components

Working on a transmission can be dangerous. Here are some key safety considerations:

- Weight: Transmissions are heavy! Use a proper transmission jack when removing or installing one. Dropping a transmission can cause serious injury.

- Hydraulic Pressure (Automatic): Automatic transmissions operate under high hydraulic pressure. Relieve the pressure before disconnecting any lines or components.

- Hot Fluid: Transmission fluid can get very hot. Let the transmission cool down before working on it to avoid burns.

- Chemicals: Transmission fluid and cleaning solvents can be harmful. Wear gloves and eye protection.

- Support the Vehicle Properly: Always use jack stands when working underneath a vehicle. Never rely solely on a jack.

Always disconnect the negative battery cable before working on any electrical components.

Furthermore, if you suspect internal damage to the transmission (like broken gears or a faulty torque converter), it's often more cost-effective to replace the entire unit with a rebuilt or remanufactured transmission. Rebuilding a transmission requires specialized tools and knowledge.

In conclusion, understanding the transmission in your car is a valuable asset for any car enthusiast or DIY mechanic. From diagnosing problems to performing maintenance, this knowledge empowers you to take better care of your vehicle. The transmission is a complex component, but with a bit of study and care, you can keep it running smoothly for years to come.