What Is The Transmission Of A Car

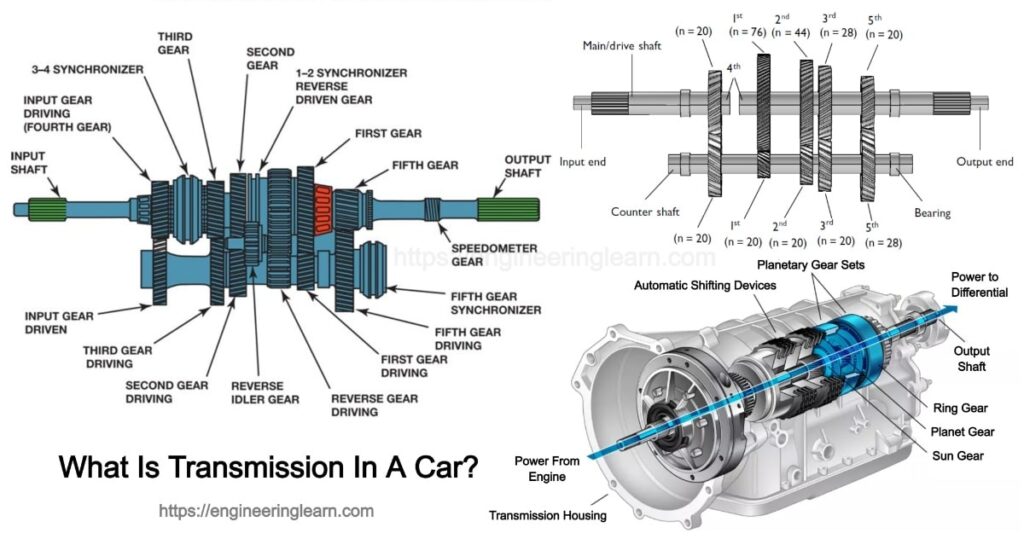

Understanding your car's transmission is crucial, whether you're planning a rebuild, troubleshooting a nagging problem, or simply expanding your automotive knowledge. This article provides a detailed overview of transmission systems, breaking down their purpose, key components, operation, and basic troubleshooting. We'll cover both automatic and manual transmissions, highlighting their similarities and differences. Knowing the intricacies of your transmission empowers you to make informed decisions about maintenance and repairs, potentially saving you significant time and money. The diagram we have available for download provides a visual aid to complement this information, making it easier to grasp the complex relationships between the various parts.

Purpose: Power Transfer and Gear Ratio Control

The primary purpose of the transmission is to transfer the power generated by the engine to the wheels. It achieves this while also allowing the engine to operate within its optimal RPM range, regardless of the vehicle's speed. Without a transmission, your engine would struggle to provide sufficient torque at low speeds and would quickly over-rev at higher speeds, leading to inefficiency and potential damage. Think of it like a bicycle: you shift gears to make pedaling easier on hills or to go faster on flat ground. The transmission performs a similar function for your car.

Specifically, the transmission:

- Increases Torque: At lower speeds, the transmission provides a higher gear ratio, multiplying the engine's torque output to overcome inertia and acceleration.

- Reduces Speed: At higher speeds, the transmission shifts to lower gear ratios, reducing the engine's RPM for fuel efficiency and reduced wear.

- Provides Neutral: Allows the engine to run without transmitting power to the wheels.

- Enables Reverse: Allows the vehicle to move backward.

Key Specs and Main Parts

Transmissions come in two main types: manual and automatic. While they achieve the same goal, their internal mechanisms differ significantly.

Manual Transmission:

- Input Shaft: Receives power directly from the engine's flywheel via the clutch.

- Output Shaft: Delivers power to the driveshaft and ultimately to the wheels.

- Gears: Various sized gears arranged in pairs on the input and output shafts. The ratio between these gear pairs determines the gear ratio for each speed.

- Synchronizers (Synchros): Allow smooth engagement of gears by matching the speeds of the gears being meshed. Worn synchros are a common cause of grinding when shifting.

- Shift Forks: Move the synchronizers to engage different gears.

- Shift Linkage: Connects the gear shift lever in the cabin to the shift forks inside the transmission.

- Clutch: A mechanical device that connects and disconnects the engine from the transmission, allowing for gear changes.

Automatic Transmission:

- Torque Converter: Replaces the clutch in a manual transmission. It uses fluid to transfer power from the engine to the transmission, allowing the engine to idle without stalling.

- Planetary Gear Sets: Complex gear systems that provide different gear ratios.

- Clutches and Bands: Engage and disengage different planetary gear sets to change gears.

- Valve Body: A hydraulic control center that directs transmission fluid to the clutches and bands, controlling gear shifts.

- Transmission Control Module (TCM): An electronic control unit that monitors various sensors and controls the valve body to achieve optimal shifting.

- Transmission Fluid: A specialized fluid that lubricates, cools, and transmits hydraulic pressure within the transmission.

Key Specs: Transmission specifications often include the number of gears (e.g., 5-speed manual, 6-speed automatic), gear ratios, and torque capacity. Understanding these specs is important when selecting a transmission for a specific application or when upgrading for increased performance.

Symbols: Interpreting Transmission Diagrams

Transmission diagrams utilize standard symbols to represent components and their relationships. Common symbols include:

- Solid Lines: Typically represent mechanical connections, such as shafts, gears, and linkages.

- Dashed Lines: Often indicate hydraulic lines or electrical wiring.

- Circles: Usually represent gears or bearings.

- Rectangles: Can represent valves, solenoids, or other control devices.

- Arrows: Indicate the direction of motion or fluid flow.

Color coding may also be used to differentiate between different systems, such as lubrication lines (often colored green or blue) and hydraulic control lines (often colored red or orange). Pay close attention to the diagram's legend or key to understand the specific meaning of each symbol and color.

How It Works: From Engine to Wheels

Manual Transmission Operation:

When you press the clutch pedal, the engine is disconnected from the transmission. You then move the gear shift lever to select the desired gear. This action moves the shift forks, which engage the appropriate synchronizer to mesh the corresponding gears on the input and output shafts. When you release the clutch pedal, the engine is reconnected to the transmission, and power flows through the selected gear set to the wheels.

Automatic Transmission Operation:

The torque converter constantly transmits power from the engine to the transmission. The TCM monitors vehicle speed, engine load, and throttle position to determine the optimal gear. It then signals the valve body to direct hydraulic pressure to the appropriate clutches and bands, engaging the corresponding planetary gear set. This process allows for smooth and automatic gear changes without the need for a clutch pedal.

Real-World Use: Basic Troubleshooting Tips

Here are some common transmission problems and basic troubleshooting tips:

- Manual Transmission:

- Grinding during shifting: Worn synchronizers are the most likely cause.

- Difficulty shifting: Could be caused by a worn clutch, damaged shift linkage, or low transmission fluid.

- Popping out of gear: Indicates worn gears or shift forks.

- Automatic Transmission:

- Slipping gears: Often caused by low or contaminated transmission fluid, worn clutches, or a faulty valve body.

- Rough shifting: Can be caused by a faulty valve body, TCM issues, or incorrect transmission fluid.

- Delayed engagement: May indicate low transmission fluid or a worn torque converter.

Checking Transmission Fluid: Regularly check your transmission fluid level and condition. Low fluid can cause serious damage. The fluid should be bright red and free of debris. Dark, burnt-smelling fluid indicates a problem. Consult your vehicle's owner's manual for the proper fluid type and checking procedure.

Safety: Highlighting Risky Components

Working on a transmission can be dangerous. Always disconnect the battery before starting any work. Here are some specific safety considerations:

- Transmission Fluid: Hot transmission fluid can cause burns. Allow the transmission to cool down before draining the fluid. Wear gloves to protect your skin.

- Springs: Some transmissions contain strong springs that can cause injury if released unexpectedly. Use appropriate tools and follow the manufacturer's instructions carefully.

- Weight: Transmissions are heavy. Use a transmission jack or other appropriate lifting equipment to support the transmission during removal and installation.

- Torque Converter (Automatic): The torque converter is filled with fluid and can be heavy. Support it properly when removing it.

- Seals and Gaskets: Replacing seals and gaskets requires care. Damaged seals can lead to leaks and performance problems.

If you are not comfortable performing a particular repair, it is best to consult a qualified mechanic.

We have a detailed transmission diagram available for download to further assist your understanding. The diagram provides a visual reference for the components and their relationships, making it easier to follow along with the explanations provided in this article. Feel free to use it as a tool for learning and troubleshooting your vehicle's transmission.