What Is The Transmission On A Car

Let's dive deep into the heart of your car's drivetrain: the transmission. This article isn't just a casual overview; it's a technical guide designed for the experienced DIYer, the budding modder, and anyone who wants to truly understand how their car converts engine power into motion. We'll cover the inner workings, key components, basic troubleshooting, and even safety considerations. Think of this as your transmission's anatomy lesson – and we'll keep it practical.

Purpose: Why Bother Understanding Your Transmission?

Why should you care about the intricacies of your transmission? Well, for starters, understanding its function and components is crucial for:

- DIY Repairs and Maintenance: Knowing how the transmission works allows you to diagnose problems more accurately, perform basic maintenance (like fluid changes), and even tackle minor repairs yourself, saving you a bundle in labor costs.

- Performance Modifications: If you're planning to modify your car for increased performance, understanding the transmission is paramount. You'll need to know how it will handle the increased power and torque, and whether upgrades are necessary.

- Preventive Maintenance: By understanding how the transmission operates, you can anticipate potential issues and take preventive measures to prolong its life.

- Informed Decision-Making: When faced with a major repair or replacement, understanding the transmission empowers you to make informed decisions and avoid being taken advantage of.

Plus, let’s be honest, it's just plain cool to know how things work!

Key Specs and Main Parts

The transmission's primary job is to provide a variable gear ratio between the engine and the wheels. This allows the engine to operate within its optimal RPM range regardless of the vehicle's speed. This is done using a series of gears. Here's a breakdown of the key parts:

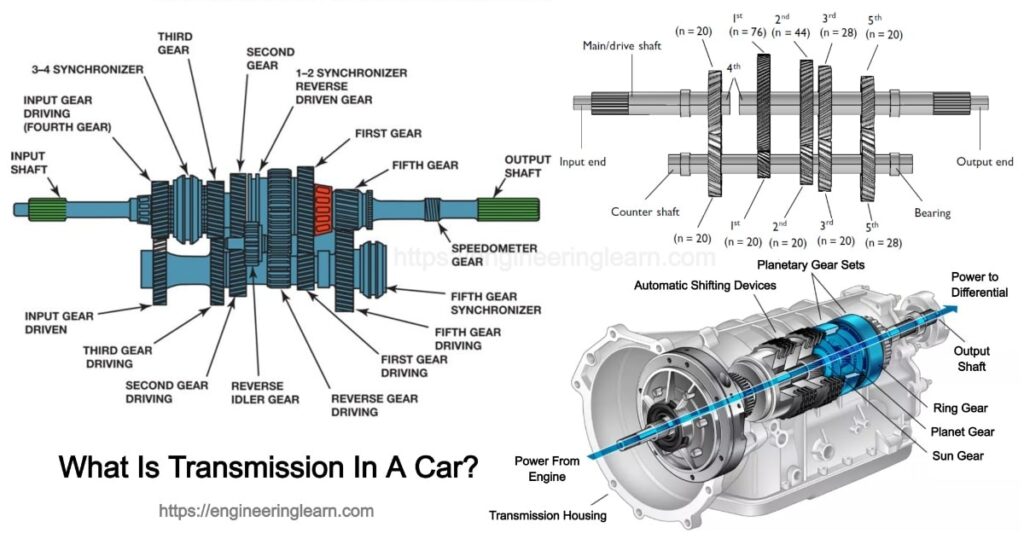

Manual Transmission

- Input Shaft: The shaft that receives power directly from the engine via the clutch.

- Output Shaft: The shaft that transmits power to the driveshaft and ultimately to the wheels.

- Gears: Sets of gears with different ratios are arranged on the input and output shafts. These are what provide the different speeds.

- Synchronizers (Synchros): These devices match the speed of the gears before they engage, preventing grinding and damage. They are essential for smooth shifting.

- Shift Forks: Mechanical components moved by the gear selector that engage the synchronizers to shift gears.

- Shift Linkage: A system of rods, cables, or levers that connects the gear selector to the shift forks.

- Clutch: A mechanical device that disconnects the engine from the transmission, allowing for gear changes. (Not technically *in* the transmission, but critical to its operation).

- Transmission Case: The housing that encloses and protects all the internal components.

Automatic Transmission

- Torque Converter: Replaces the clutch in a manual transmission. It uses fluid dynamics to transmit power from the engine to the transmission. It provides torque multiplication at low speeds.

- Planetary Gear Sets: Complex arrangements of gears (sun gear, planet gears, ring gear) that provide different gear ratios.

- Valve Body: The "brain" of the automatic transmission. It controls the flow of hydraulic fluid to the various clutches and bands, based on input from sensors and the driver.

- Clutches and Bands: These engage and disengage different planetary gear sets to change gear ratios. Bands are typically used to hold certain planetary components stationary.

- Transmission Fluid Pump: Supplies hydraulic pressure to operate the clutches, bands, and valve body.

- Transmission Control Unit (TCU): An electronic control module that monitors various sensors and controls the valve body to optimize shifting.

Key Specs: Transmission specs include the number of gears (e.g., 5-speed, 6-speed), gear ratios for each gear, and torque capacity (the maximum amount of torque the transmission can handle without failing). For automatic transmissions, other specs include shift points (RPM at which the transmission shifts gears) and the type of fluid used (e.g., ATF, Dexron, Mercon).

How It Works

Manual Transmission

The engine's crankshaft spins the input shaft of the transmission. When you press the clutch pedal, you disconnect the engine from the transmission. Then, you select a gear using the gear selector. This moves a shift fork, which engages a synchronizer. The synchronizer matches the speed of the selected gear to the speed of the output shaft. Once the speeds are matched, the selected gear locks onto the output shaft. When you release the clutch pedal, the engine's power is transmitted through the engaged gear to the output shaft, which then drives the wheels.

Automatic Transmission

The torque converter transfers power from the engine to the transmission using fluid. Inside the torque converter is an impeller (connected to the engine), a turbine (connected to the transmission), and a stator. The impeller spins, flinging fluid towards the turbine, causing it to spin as well. The stator redirects the fluid flow, increasing torque. The valve body, controlled by the TCU, directs hydraulic fluid to engage specific clutches and bands. These clutches and bands lock different components of the planetary gear sets, resulting in different gear ratios. The TCU monitors vehicle speed, engine load, and other factors to determine the optimal time to shift gears. This is a simplified explanation, but covers the core principles.

Real-World Use – Basic Troubleshooting Tips

Here are some common transmission problems and basic troubleshooting tips:

Manual Transmission

- Difficulty Shifting: Could be due to a worn clutch, damaged synchronizers, or low transmission fluid. Check the clutch cable/linkage for proper adjustment. Check/replace transmission fluid.

- Grinding Gears: Usually indicates worn synchronizers. Requires professional repair or replacement.

- Popping Out of Gear: Can be caused by worn gears, shift linkage problems, or internal damage.

- Clutch Slippage: The engine revs up without the car accelerating. Indicates a worn clutch.

Automatic Transmission

- Slipping Gears: The transmission shifts erratically or fails to hold a gear. Could be due to low fluid level, worn clutches or bands, or a malfunctioning valve body. Check the fluid level and condition.

- Rough Shifting: Harsh or jerky gear changes can be caused by a malfunctioning valve body, solenoid issues, or contaminated transmission fluid.

- Delayed Engagement: A delay between shifting into drive or reverse and the car moving. Often indicates low fluid level or internal damage.

- Fluid Leaks: Check for leaks around the transmission pan, seals, and cooler lines.

Important: Always check the transmission fluid level and condition first. Low or dirty fluid is a common cause of many transmission problems. Use the correct type of fluid specified in your vehicle's owner's manual.

Safety – Risky Components

Working on a transmission can be dangerous. Here are a few safety considerations:

- Hot Surfaces: The transmission can get very hot, especially after driving. Allow it to cool completely before working on it.

- Heavy Components: Transmissions are heavy and awkward to handle. Use proper lifting equipment and get assistance when needed.

- Pressurized Fluid: Automatic transmissions operate under high hydraulic pressure. Relieve the pressure before disconnecting any lines or components.

- Springs and Retainers: Disassembling a transmission involves dealing with compressed springs and retainers. Use caution and wear safety glasses to protect your eyes.

- Eye Protection: Always wear safety glasses when working on any part of your car to avoid eye injuries.

- Transmission Fluid: Transmission fluid contains harmful chemicals. Avoid contact with skin and eyes. Dispose of used fluid properly.

If you are not comfortable working on your transmission, it is best to consult a qualified mechanic.